Fuel-supply unit for a motor vehicle

A fuel supply and motor vehicle technology, which is applied to machines/engines, charging systems, mechanical equipment, etc., can solve problems such as short service life, high power consumption, noise, etc., and achieve the effect of simple structure and simple fuel supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

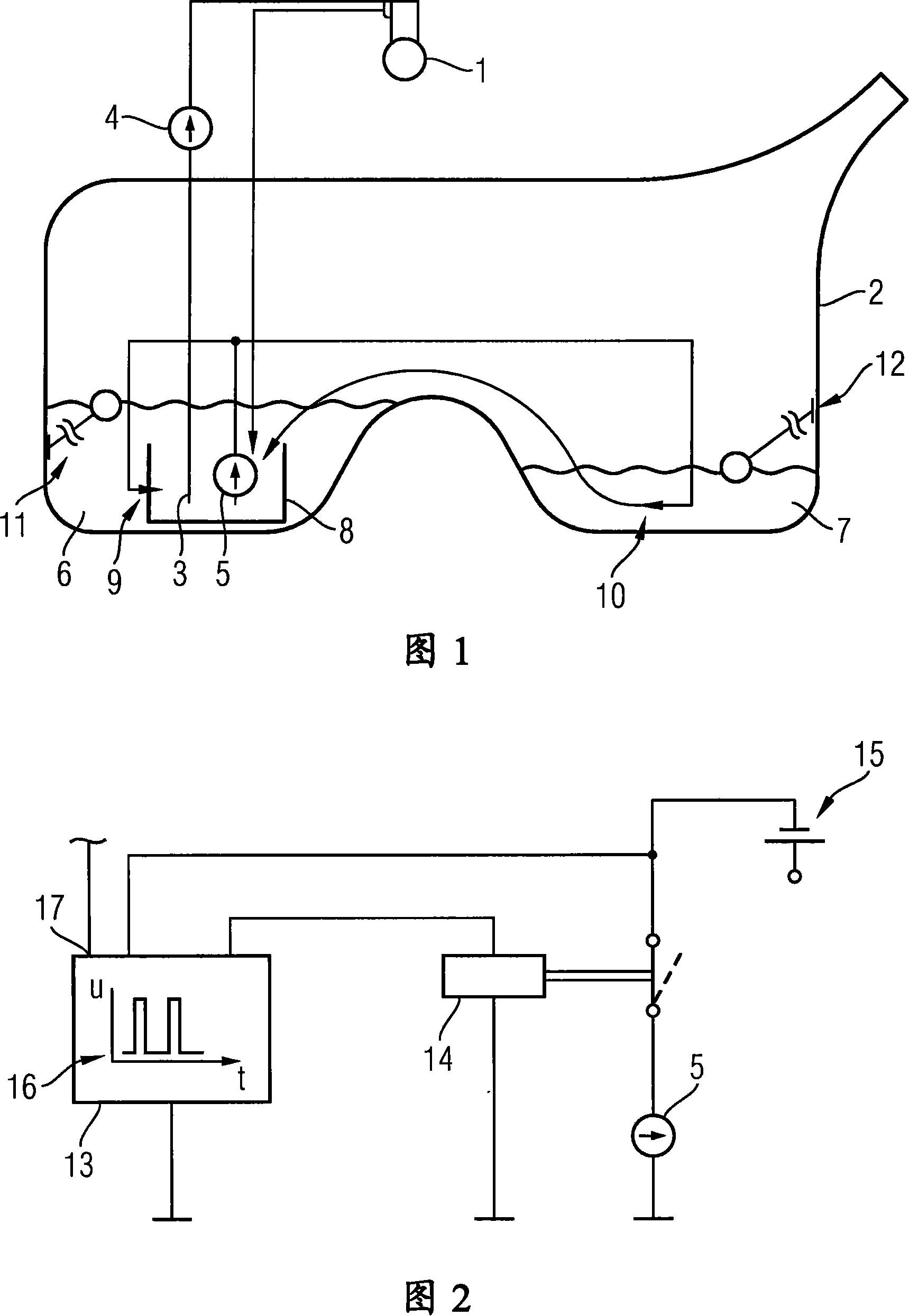

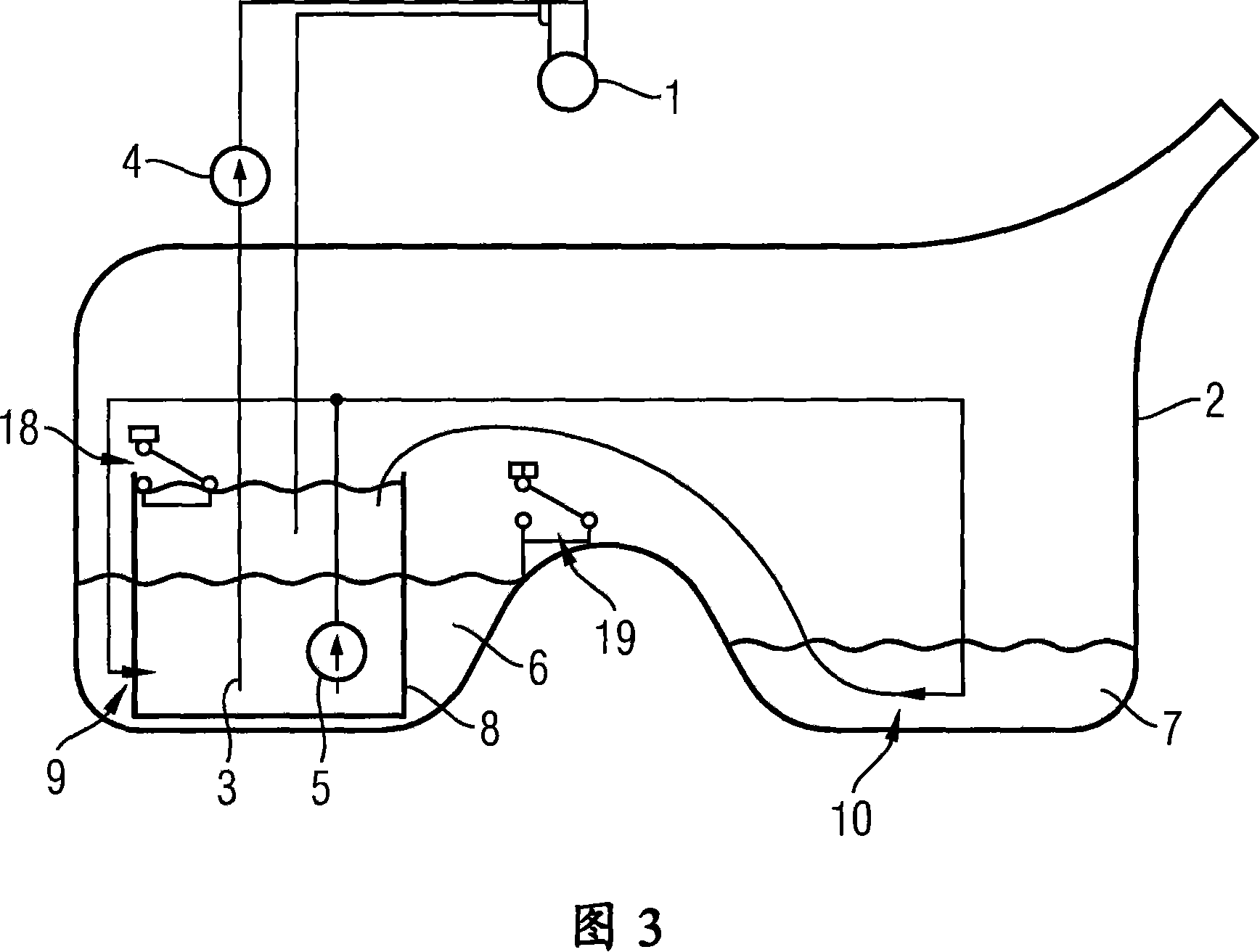

[0022] FIG. 1 schematically shows a fuel supply system for supplying fuel to an internal combustion engine 1 of a motor vehicle operating on the diesel principle. The fuel supply device has a main fuel pump 4 and a delivery pump 5 that sucks fuel through a suction connection 3 protruding into the fuel tank 2, and the delivery pump delivers the fuel in the fuel tank 2 to the suction of the main fuel pump 4. Oil joint 3. The main fuel pump 4 can be, for example, a mechanically driven high-pressure diesel pump. The fuel tank 2 is designed as a so-called saddle tank with two chambers. The main fuel pump 4 is arranged outside the fuel tank 2 , while the suction connection 3 and the delivery pump 5 are arranged inside a swirl box 8 preloaded to the bottom of the fuel tank 2 . Arranged in the chambers 6 , 7 are ejector pumps 9 , 10 which are supplied with fuel as drive medium by the delivery pump 5 and which convey the fuel from the chambers 6 , 7 into the swirl box 8 . Furthermor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com