Synthesis, split and racemization method for preparing chirality medicament levetiracetam midbody (S)-(+)-2-amido butyramide hydrochlorate

A technology of aminobutyramide and chiral drugs is applied in the field of preparation of chiral drug intermediates to achieve the effects of cost reduction, pollution reduction and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1.1: Preparation of 2-aminobutyric acid

[0041] In a 5000ml flask, 1500ml of 28% ammonia water was added, and 500g of 2-bromobutyric acid was added dropwise at room temperature. After the dropwise addition was completed, the mixture was heated to 40° C. and reacted for 12 hours. It was concentrated to dryness under reduced pressure, and the residual solid was purified with methanol to obtain 220 g of white crystalline 2-aminobutyric acid with a yield of 71% and a content of 99.45%.

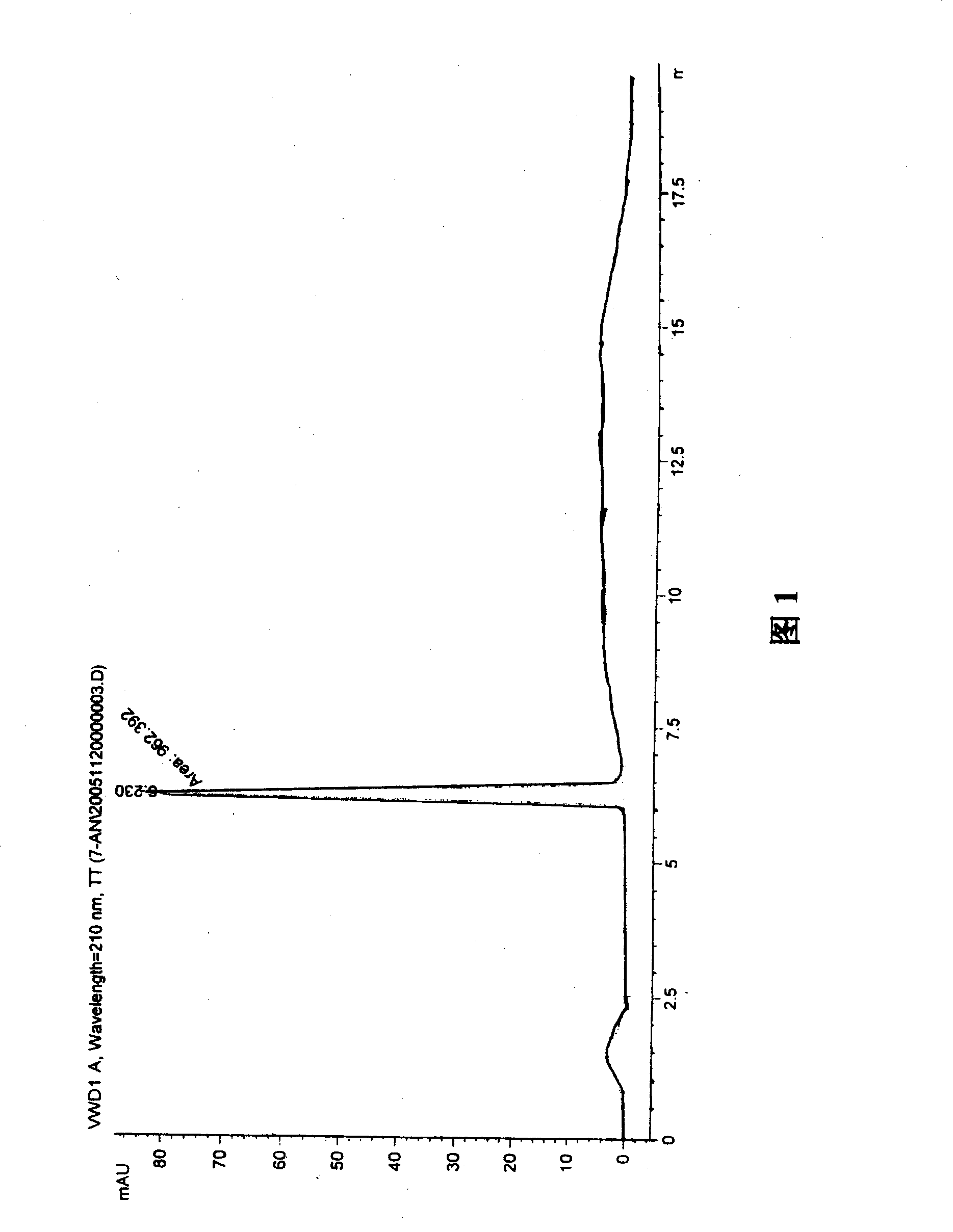

[0042] 1.2: Preparation of the swirled free base (±)-2-aminobutanamide

[0043] In a 2000ml flask, add 88g (0.854mol) 2-aminobutyric acid, 600ml methanol, cool to below 0°C, add dropwise 142.6g (1.2mol) thionyl chloride, after the dropwise addition, reflux for 3 hours and concentrate under reduced pressure Remove methanol, add 400 ml of ammonia water, extract with 400 ml of dichloromethane, dry over anhydrous magnesium sulfate, filter, concentrate under reduced pressure to remove the solv...

Embodiment 2

[0050] 2.1: Preparation of 2-aminobutyric acid

[0051] In a 5000ml flask, 2400ml of 28% ammonia water was added, and 800g of 2-bromobutyric acid was added dropwise at room temperature. After the addition was completed, it was heated to 40°C and reacted for 12 hours. It was concentrated to dryness under reduced pressure, and the residual solid was refined with methanol to obtain 340 g of white crystal 2-aminobutyric acid with a yield of 68.9% and a content of 99.3%.

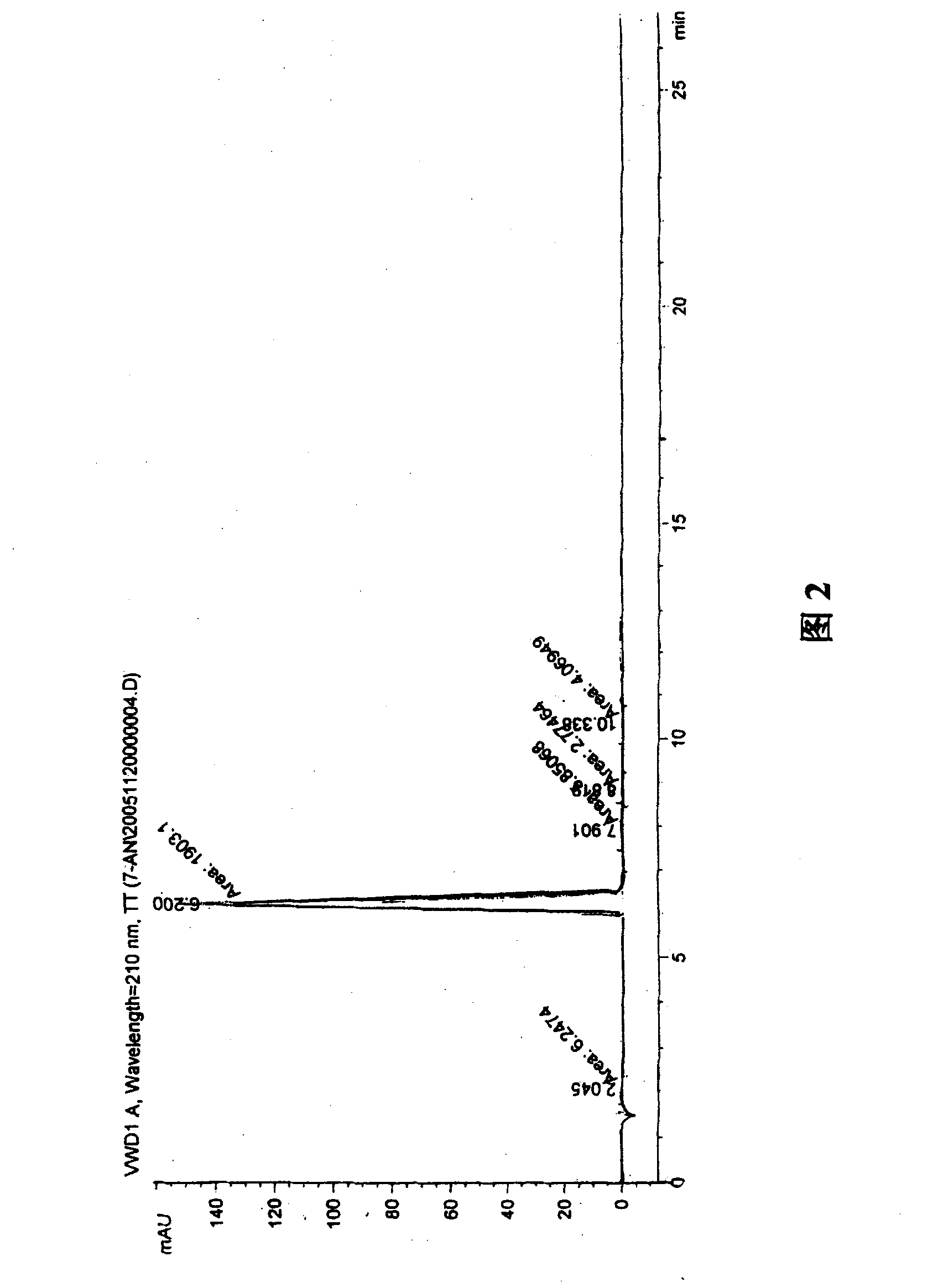

[0052] 2.2: Preparation of vortexed free base (±)-2-aminobutyramide

[0053] In a 5000ml flask, add 325g of 2-aminobutyric acid and 2200ml of methanol, cool to below 0°C, add 527g (1.2mol) of thionyl chloride dropwise, after the dropwise addition, reflux for 3 hours, concentrate under reduced pressure to remove methanol, and add 1480ml of ammonia water , extracted with 1500ml of dichloromethane, dried over anhydrous magnesium sulfate, filtered, concentrated under reduced pressure to remove the solvent, added 244...

Embodiment 3

[0060] 3.1: Preparation of 2-aminobutyric acid

[0061] In a 5000ml flask, 2400ml of 28% ammonia water was added, and 800g of 2-bromobutyric acid was added dropwise at room temperature. After the addition was completed, it was heated to 40°C and reacted for 12 hours. It was concentrated to dryness under reduced pressure, and the residual solid was refined with methanol to obtain 355 g of white crystal 2-aminobutyric acid, with a yield of 71.9% and a content of 99.0%.

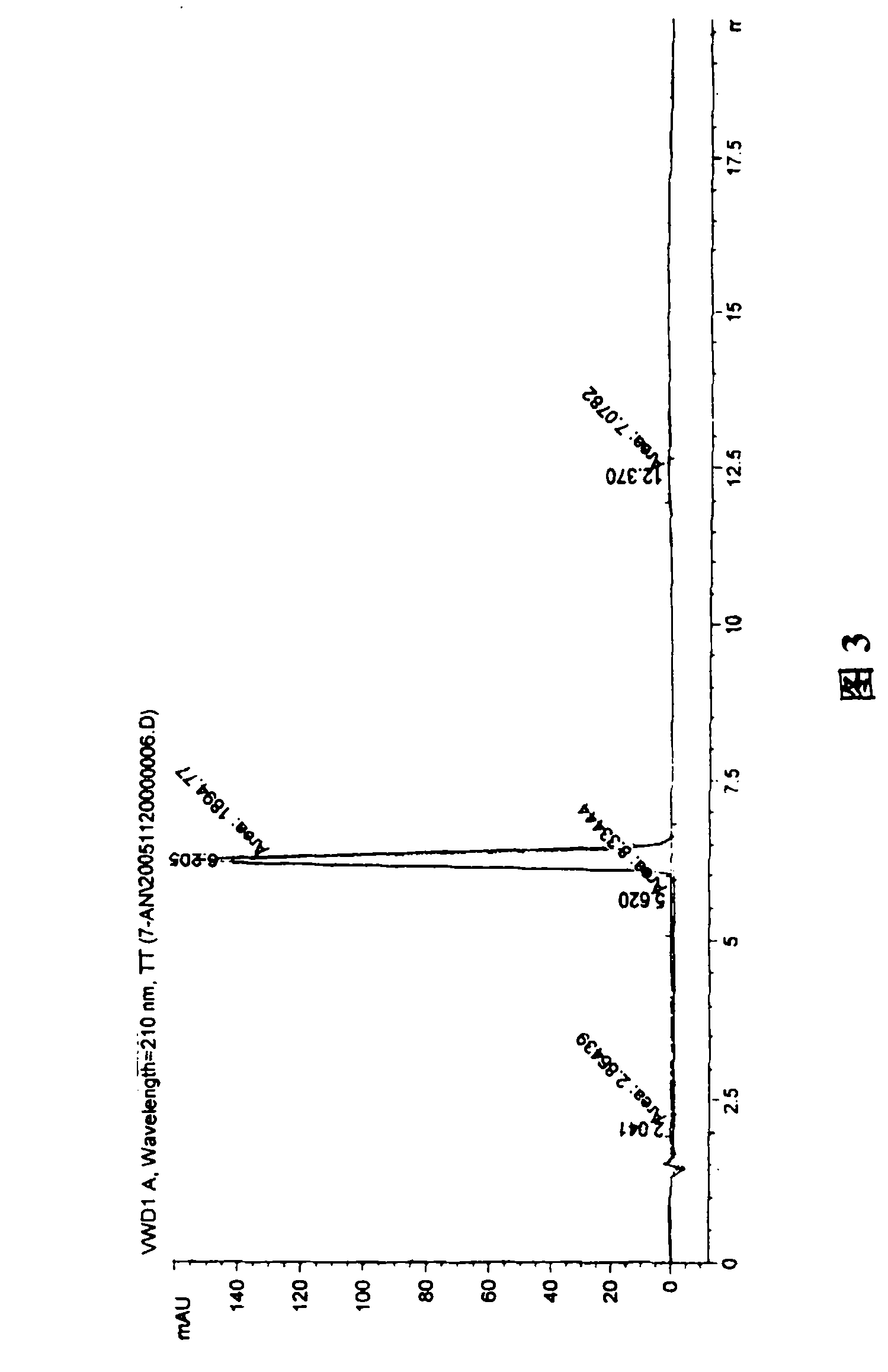

[0062] 3.2: Preparation of vortexed free base (±)-2-aminobutyramide

[0063] In a 5000ml flask, add 350g 2-aminobutyric acid and 2300ml methanol, cool to below 0°C, add 549g thionyl chloride dropwise, after the dropwise addition, reflux for 3 hours, concentrate under reduced pressure to remove methanol, add 1540ml concentrated ammonia water, use 1540ml Extract with dichloromethane, dry over anhydrous magnesium sulfate, filter, concentrate under reduced pressure to remove solvent, add 2540ml of anhydrous methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com