Back-flushing soot-cleaning device for high-efficiency dust-absorption vehicle

A technology of cleaning device and vacuuming vehicle, which is applied in cleaning methods, road cleaning, construction, etc., can solve the problems of limited use scope and weak processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

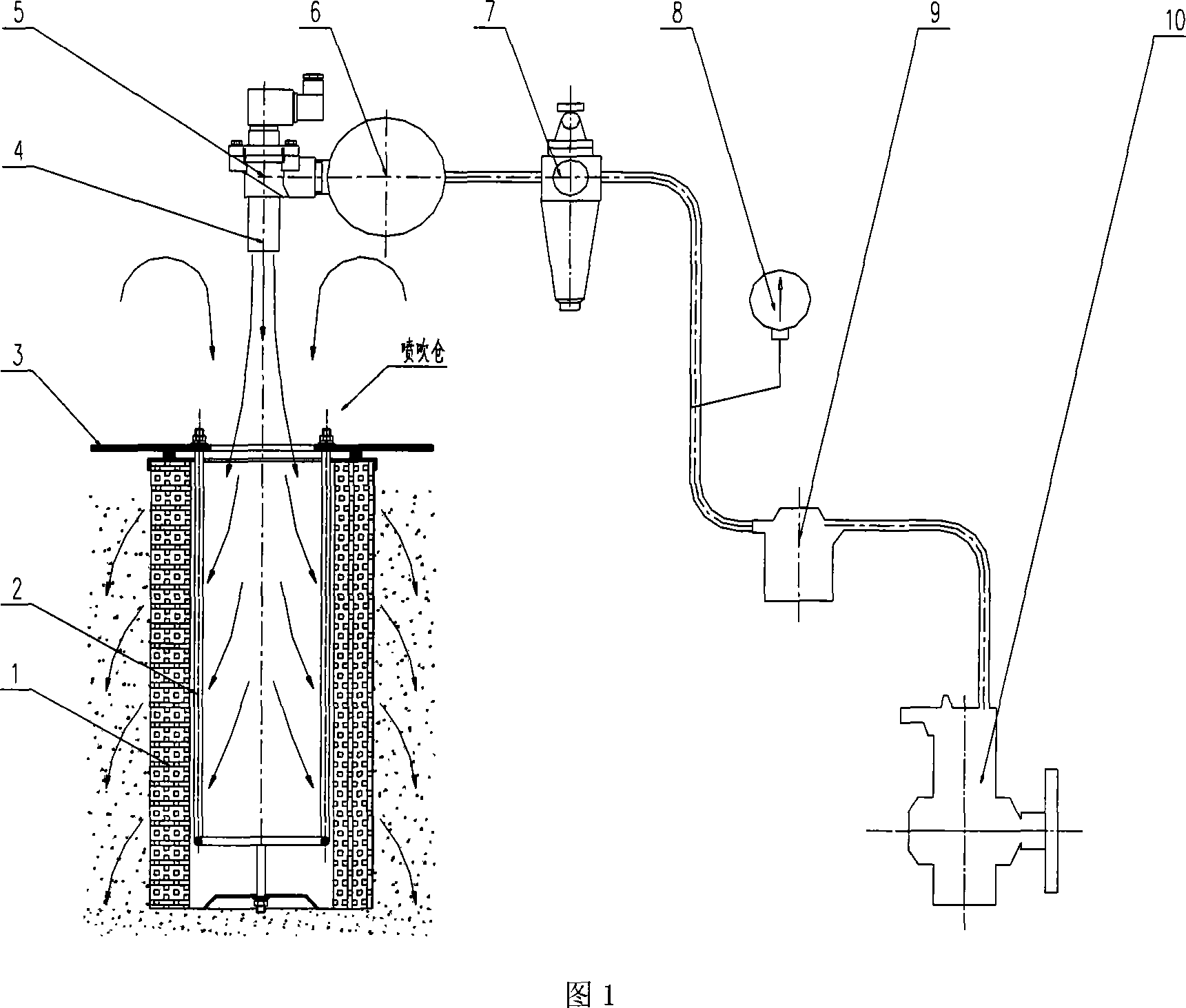

[0007] As shown in Figure 1, the present invention mainly includes: filter cartridge 1, filter cartridge hanger 2, flower plate 3, automobile special injection joint 4, special low-voltage electromagnetic pulse valve and controller 5, automobile air storage bag 6, shockproof water Gas separation device 7, anti-seismic pressure gauge 8, automobile pressure regulating valve 9, automobile air compressor 10 and related pipeline systems and electrical control systems, etc., the connection method is: filter cartridge 1 is set on the outside of filter cartridge hanger 2, filter cartridge The tube hanger 2 is connected to the flower plate 3 on the upper side, and the bottom plate of the filter tube 1 is connected to the bottom plate, so that the rubber strip on the filter tube 1 is compressed and sealed. The special low-pressure electromagnetic pulse valve 5 is placed in the injection chamber above the filter tube. The special low-pressure electromagnetic pulse valve and The controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com