Natural gas liquid charging-up pump and natural gas liquid charging-up station

A liquefied natural gas, filling pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of frequent maintenance, failure, etc., to prevent cavitation, simplify the manufacturing process, improve work stability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

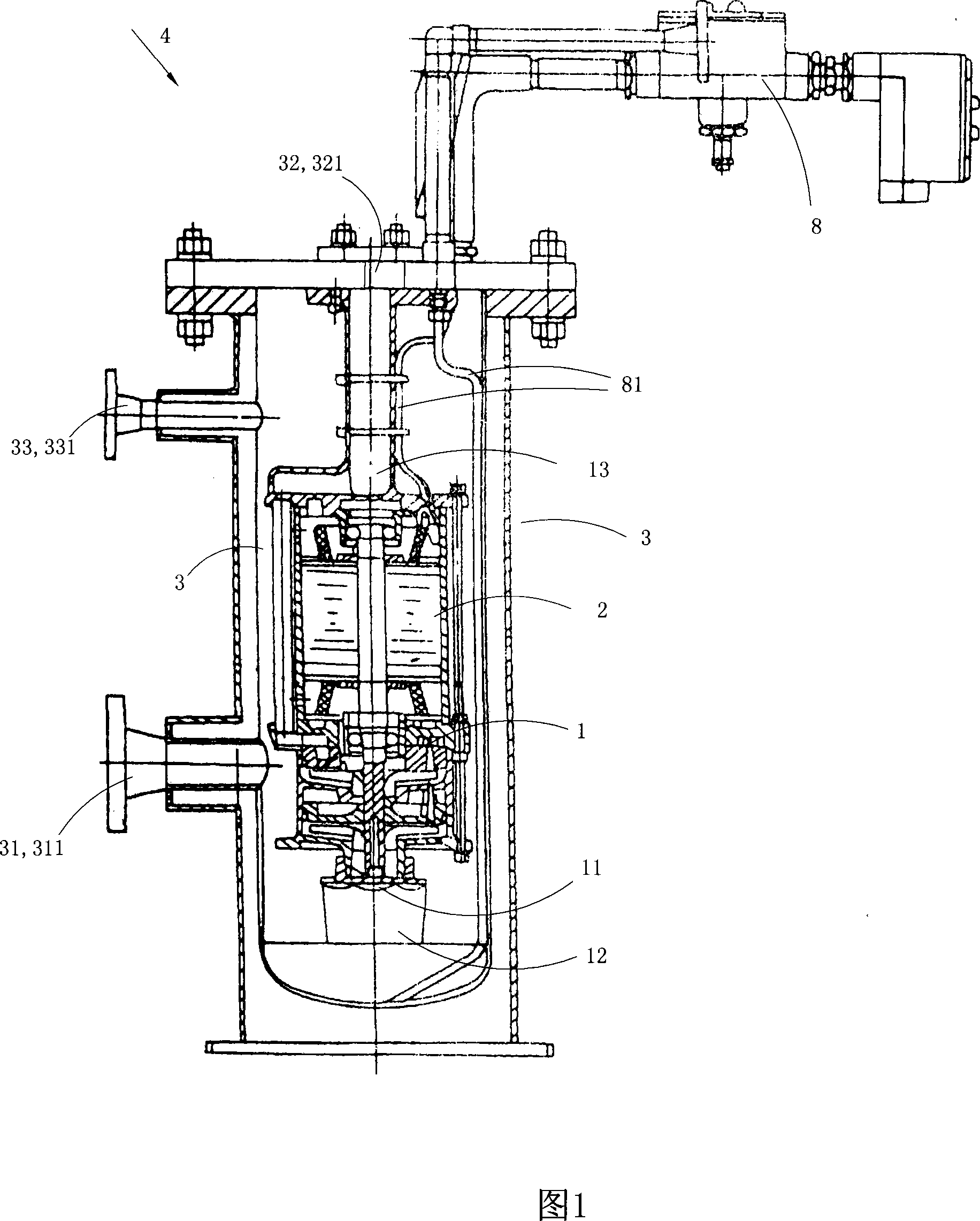

[0022] (Embodiment 1, liquefied natural gas filling pump)

[0023] As shown in Fig. 1, this embodiment is a liquefied natural gas filling pump, which has a circuit controller 8, a vertically arranged casing 3, a pump main body 1 arranged in the casing 3, and an impeller 11 that drives the rotation of the impeller 11 in the pump main body 1. The motor 2 and the circuit controller 8 are connected to the motor 2 through a wire 81; the pump body 1 is provided with a suction port 12 and a pressure outlet 13; the suction port 12 of the pump body 1 is arranged at the bottom of the pump body 1, and the pressure port 13 is set on the top of the pump main body 1, and the suction port 12 of the pump main body 1 is also provided with a deflector for avoiding cavitation; the housing 3 is provided with a liquid inlet 31, a liquid outlet 32 and an air return port 33 ; The liquid outlet 32 communicates with the pressure outlet 13 of the pump main body 1 through a pipeline. The height of ...

Embodiment 2

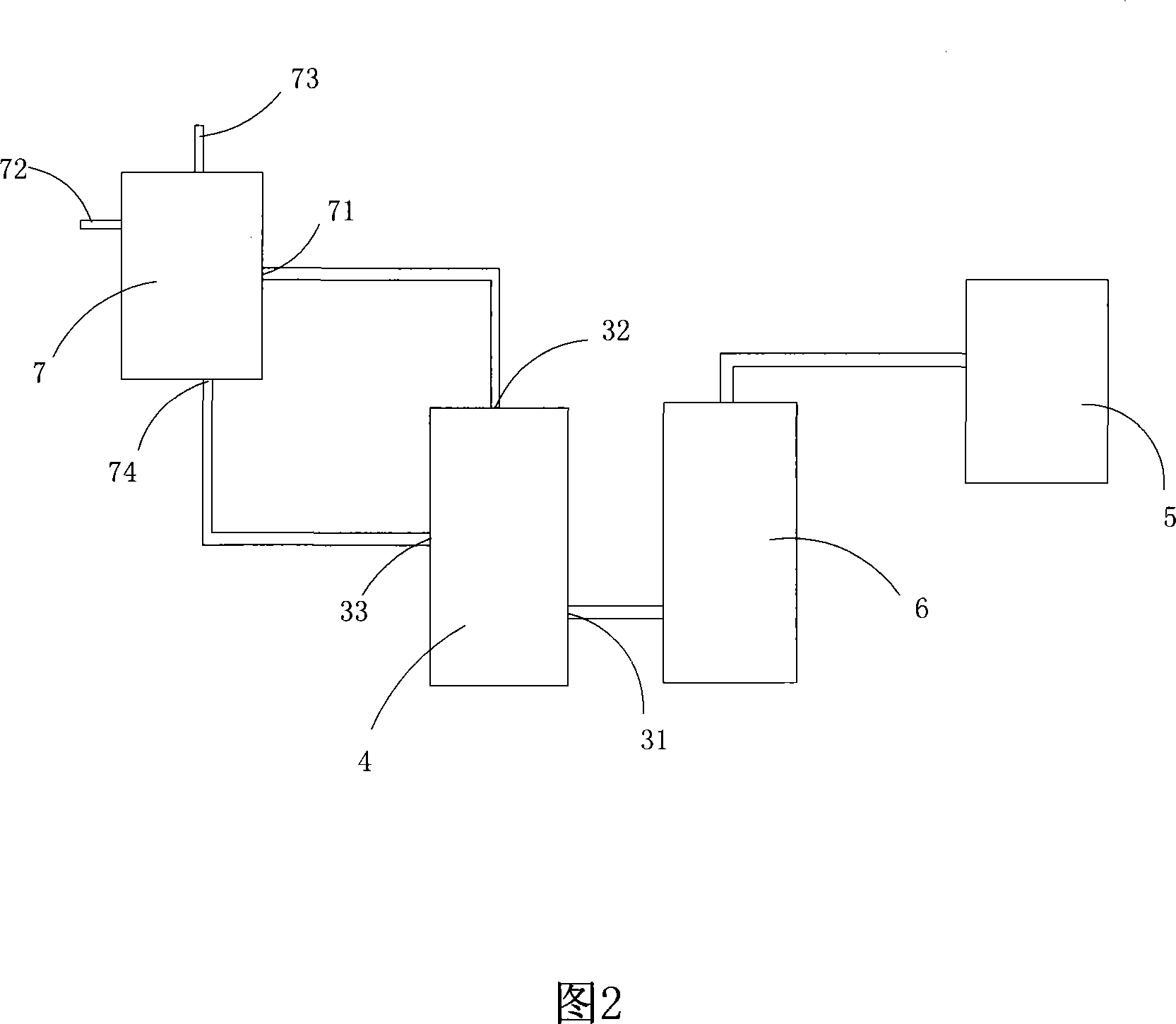

[0025] (Example 2, liquefied natural gas filling station)

[0026] As shown in Fig. 2, this embodiment is a LNG filling station formed by using the LNG filling pump 4 of Embodiment 1, including an unloading device 5 for unloading the LNG in the LNG tanker to the natural gas storage tank 6 , liquefied natural gas storage tank 6, liquefied natural gas filling pump 4 and LNG filling machine 7. The unloading equipment in this embodiment is an electric centrifugal pump; in other embodiments, a crane can also be used to directly unload the on-board gas storage tank of the LNG tanker; the liquefied natural gas filling pump 4 has a housing 3, and The pump main body 1 arranged in the housing 3 and the motor 2 that drives the impeller 11 in the pump main body 1 to rotate, the pump main body 1 is provided with a suction port 12 and a pressure outlet 13; the housing 3 is provided with a liquid inlet 31 , a liquid outlet 32 and an air return port 33; the liquid outlet 32 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com