Electric power switching device and its abnormal test method

A power conversion device and abnormal detection technology, which is applied to emergency protection circuit devices, output power conversion devices, measurement devices, etc., can solve problems such as failure to protect, inability to protect, and damage to multiple IGBT components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

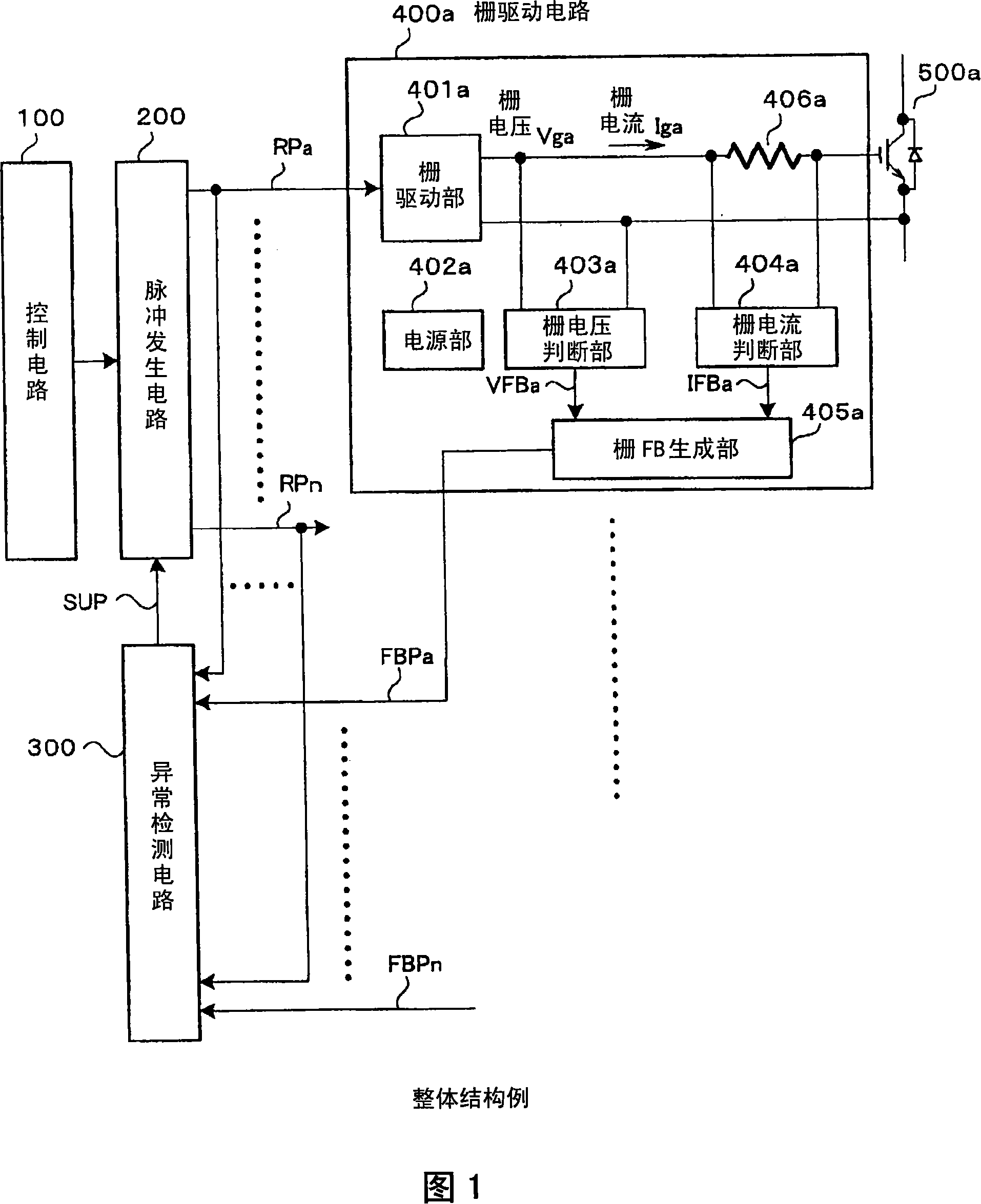

[0027] FIG. 1 is a block diagram showing a configuration example of a power conversion device according to an embodiment of the present invention. The overall structure of one embodiment of this example will be described with reference to FIG. 1 .

[0028] This example has: a control circuit 100 for controlling the operation of the power conversion device; according to the instructions of the control circuit 100, a command pulse generating mechanism, namely a pulse generating circuit 200, which generates a command pulse for instructing the on / off of the IGBT; The command pulse, corresponding to the state of the command pulse, changes the magnitude of the gate voltage applied to the gate of the IGBT, thereby performing the gate drive mechanism for turning on or off the IGBT, that is, the gate drive circuit 400a; the IGBT element 500a; and Abnormality detection circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com