Production of cold rolling high-strength ultra-deep-drawing steel plate by bell-type furnace and method for manufacturing same

A manufacturing method and high-strength technology, applied in bell-type furnaces, metal rolling, manufacturing tools, etc., can solve problems such as high energy consumption, poor control, and easy-to-break belts, and achieve low investment and high secondary resistance The effect of processing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Examples are shown in Table 3. After smelting, the slab is heated to 1230°C and held for 1 hour, then finished rolling at 910°C and coiled at 700°C, rolled to 0.8mm with a cold rolling reduction of 80%, and heated to 710°C with the furnace. After holding at ℃ for 4 hours, the furnace is cooled, and the steel plate is processed according to JIS13# and its mechanical properties are tested. The ductile-brittle transition temperature DBTT is carried out according to the GM9920P standard.

[0049] Table 3 chemical composition (wt%)

[0050] Example

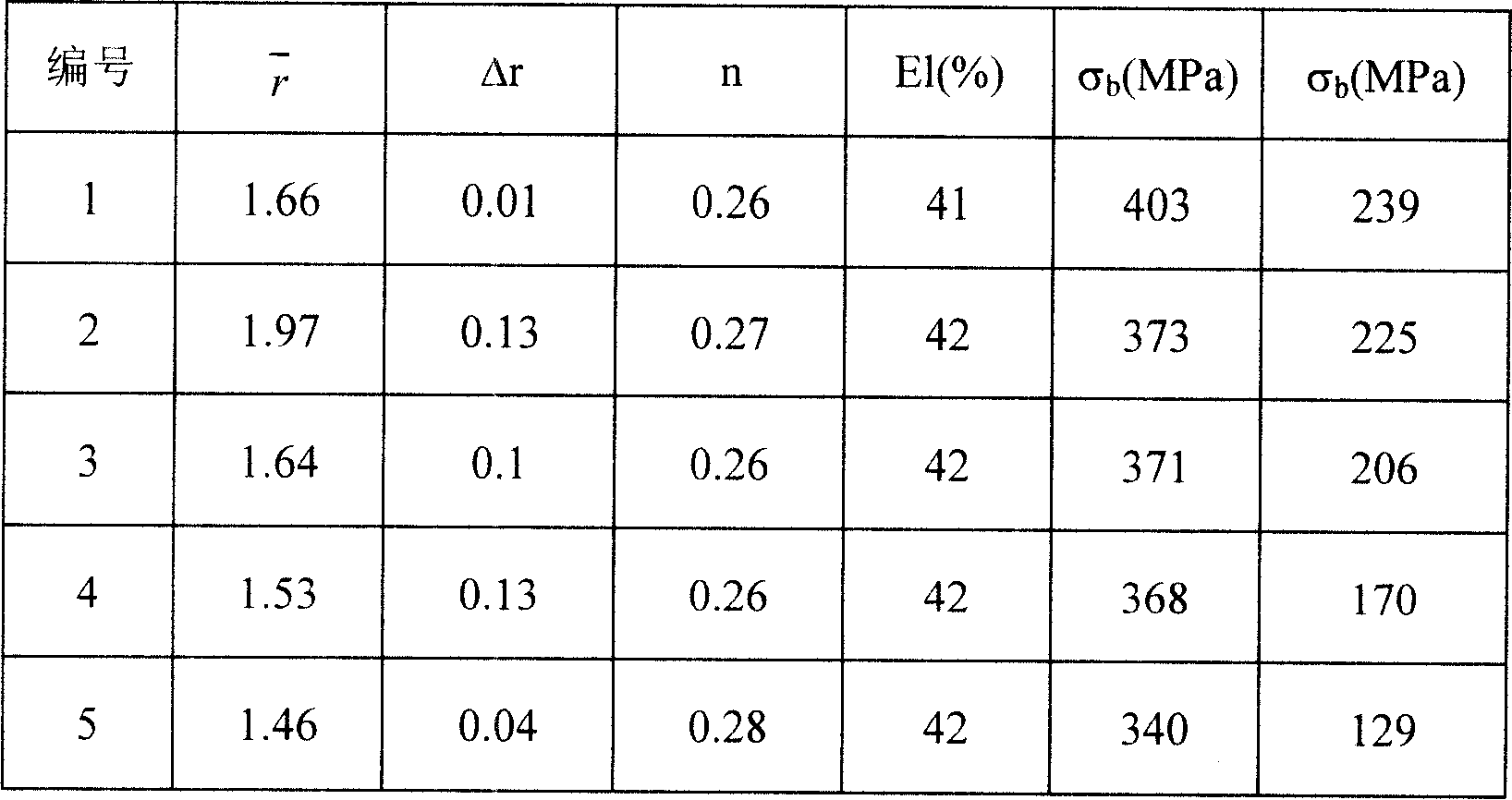

[0051] Table 4 mechanical properties

[0052]

[0053] Table 4 shows the mechanical properties of the steels of the examples after the above-mentioned process. It can be seen from the table that the ultra-deep drawing high-strength cold-rolled steel plate with excellent comprehensive properties can be produced by using the composition and process of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com