Drum type washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve the problems of insufficient cooling, increased dehydration and rinsing operations, and low rinsing effect, etc., to achieve Reduce temperature, improve rinsing effect and cooling effect, and improve rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

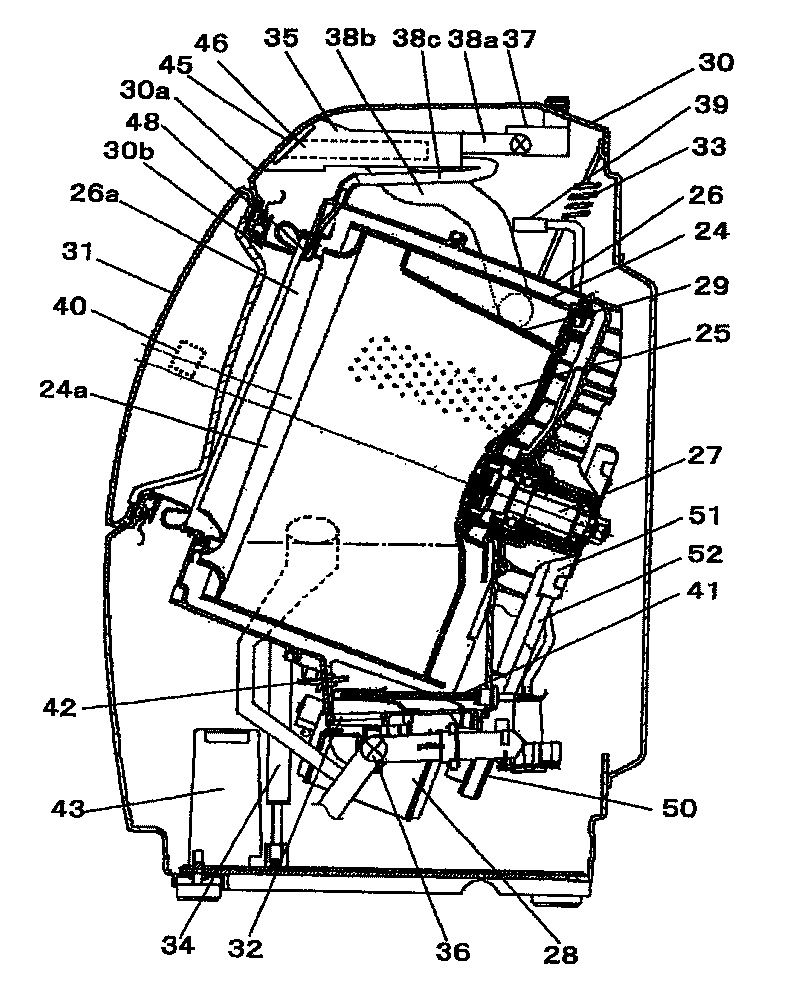

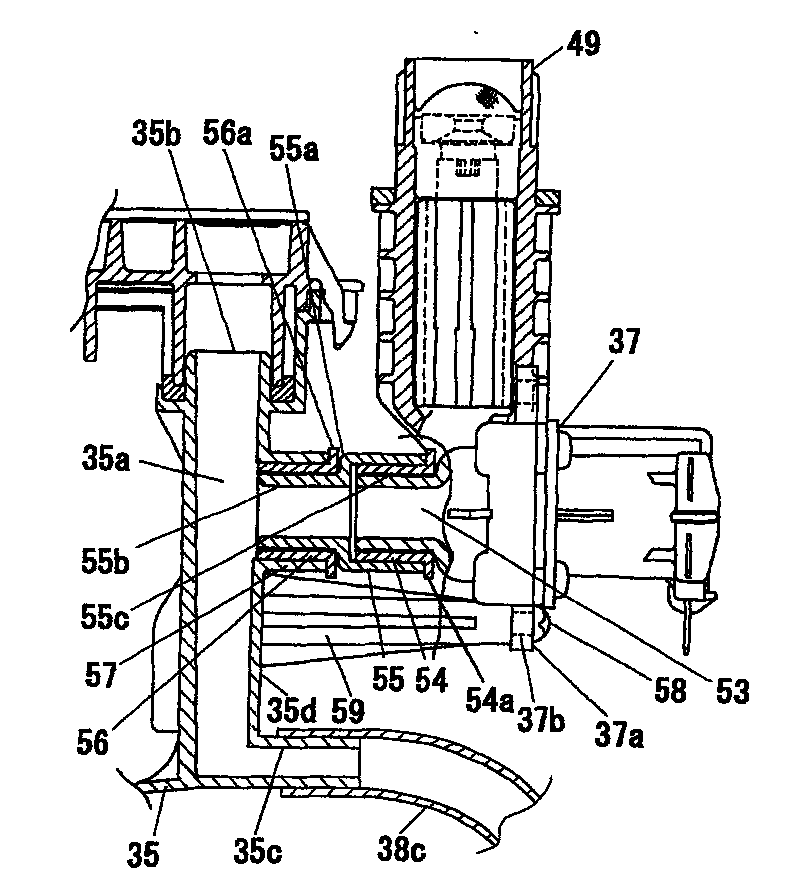

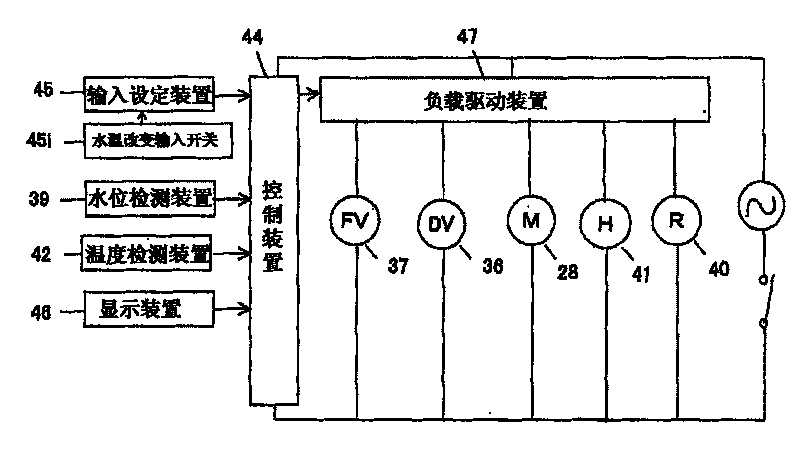

[0047] figure 1 A longitudinal sectional view of the front-loading washing machine in the first embodiment of the present invention, figure 2 It is a schematic cross-sectional view of the washing powder box and the water inlet device in the drum type washing machine, image 3 Partial block diagram of the control circuit diagram for the front-loading washing machine, Figure 4 It is an enlarged front view of the input setting device and display device in the drum type washing machine.

[0048] Such as figure 1 As shown in , the rotary drum 24 forms a cylindrical shape with a bottom, and the entire outer wall surface is provided with many water holes 25, which are arranged in the water tub 26 in a rotatable manner. The rotation center of the rotary drum 24 is provided with a rotary shaft (rotation center shaft 27) substantially in an inclined direction, and the axial direction of the rotary drum 24 is set to be inclined downward from the front side to the rear side. The tu...

Embodiment 2

[0073] Figure 5 It is a schematic operation flowchart of the above-mentioned front-loading washing machine in the second embodiment of the present invention, Figure 6 It is a schematic diagram of the rinsing operation steps of the drum type washing machine.

[0074] In the rinsing step, the control device 44 alternately executes the following two operation steps within the specified time T1: the adding and rinsing step of adding rinsing water between the first specified water level R1 and the second specified water level into the tub 26, and A drain rinse step of the drain is performed.

[0075] The other configurations are the same as those in the first embodiment, so only the same symbols are assigned here, and repeated description thereof will be omitted.

[0076] Refer below Figure 5 The flowchart in and Figure 6 The step chart in the above describes the operation and function of the above configuration.

[0077] When performing laundry operation, first open the c...

Embodiment 3

[0081] Figure 7 It is a schematic operation flow chart of the front-loading washing machine in the third embodiment of the present invention. Among them, the control device 44 operates the motor 28 during at least a part (time) of the water-adding rinsing step and the draining rinsing step in the second aspect, thereby driving the rotary drum 24 to rotate.

[0082] The other structures are the same as those of Embodiments 1 and 2 above, so only the same symbols are attached, and their repeated descriptions are omitted.

[0083] The operation in the above constitution will be described below. Figure 7 Steps 200-208 in the above are the same as steps 100-108 in Embodiment 1, so they will not be described here again.

[0084] In the rinsing step, after the drainage reaches the specified water level R3, in step 209, the control device 44 operates the water adding valve 37, and in step 210, the motor 28 starts to work, and the rotating drum 24 is stirred and rotated (such as st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com