Connecting method of limestone powder bin bracket

A technology of limestone powder and connection method, which is applied in the direction of non-removable pipe connection, welding equipment, pipe/pipe joint/pipe fitting, etc. It can achieve the effect of simple structure, high reliability and improved coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

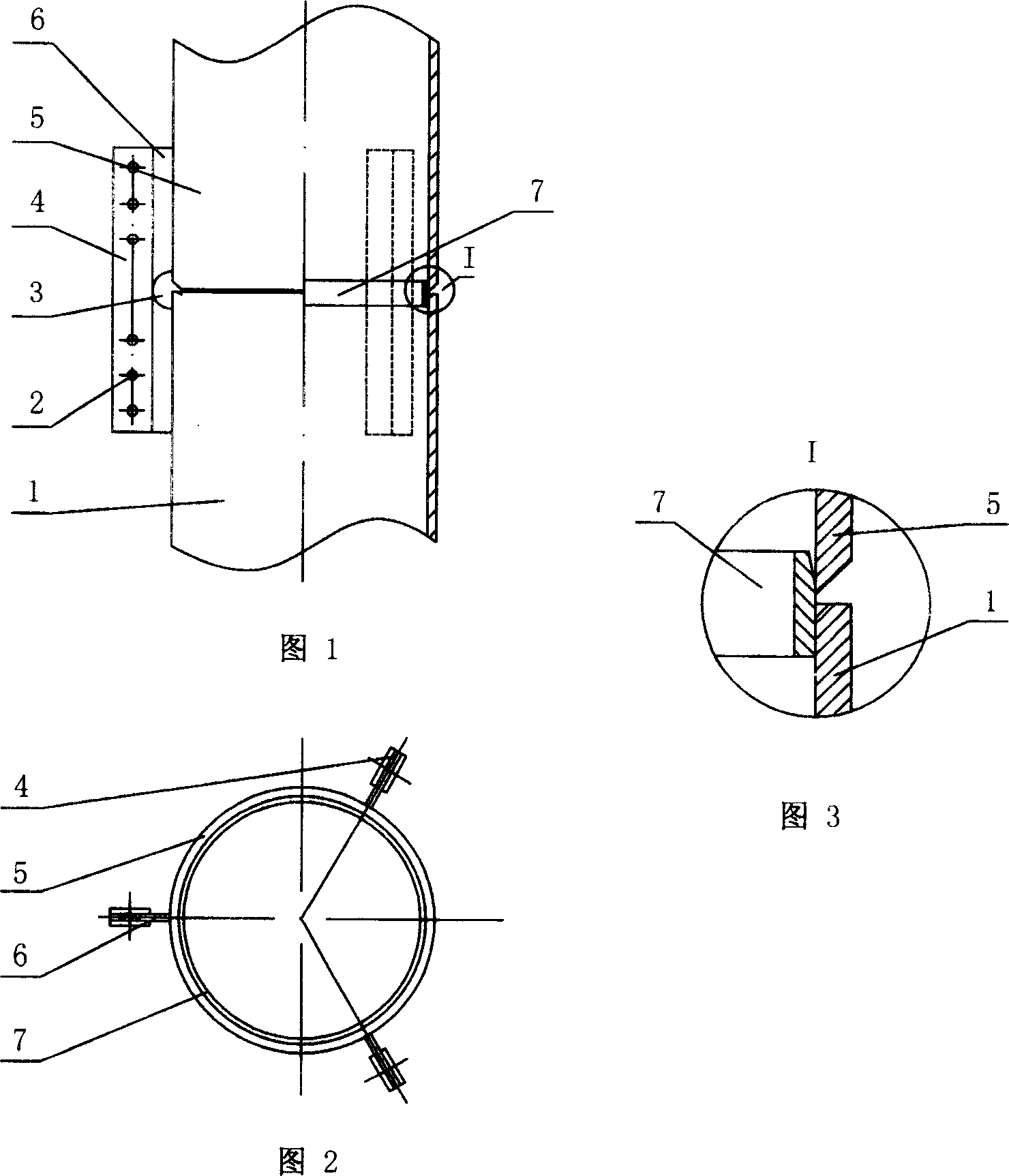

[0015] Three wing plates 6 are respectively welded at the mouths of tubes 1 and 5 of tubes A and B, and the three wing plates 6 are evenly distributed on the outer wall of the tube at 120 degrees. Each wing plate 6 is provided with a connecting hole 2, and the wing plate 6 is close to the tube. Open a 90-degree fan-shaped or triangular gap at the mouth.

[0016] There is an interference or transition fit in the tube A 1 with a lining ring 7, a part of the lining ring 7 is inserted into the mouth of the tube A 1, and a taper is opened on the ring wall of the exposed part; the tube B 5 is set on the ring 7, and the nozzles of the two tubes Leave a gap of 2-9MM between them.

[0017] Align the wing plates 6 of the two tubes 1 and 5 of A and B, and connect the corresponding wing plates 6 of the two tubes through a connecting plate 4 with a corresponding connection hole through bolts, and fasten the connection;

[0018] Weld the nozzles 1 and 5 of pipes A and B.

[0019] After we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com