Wafer testing module

A chip testing and chip technology, which is applied in the field of semiconductor testing equipment, can solve the problems of increasing failure rate, shutting down or restarting, and increasing the burden of online testers, etc., and achieves the effect of low production cost and thin and light appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

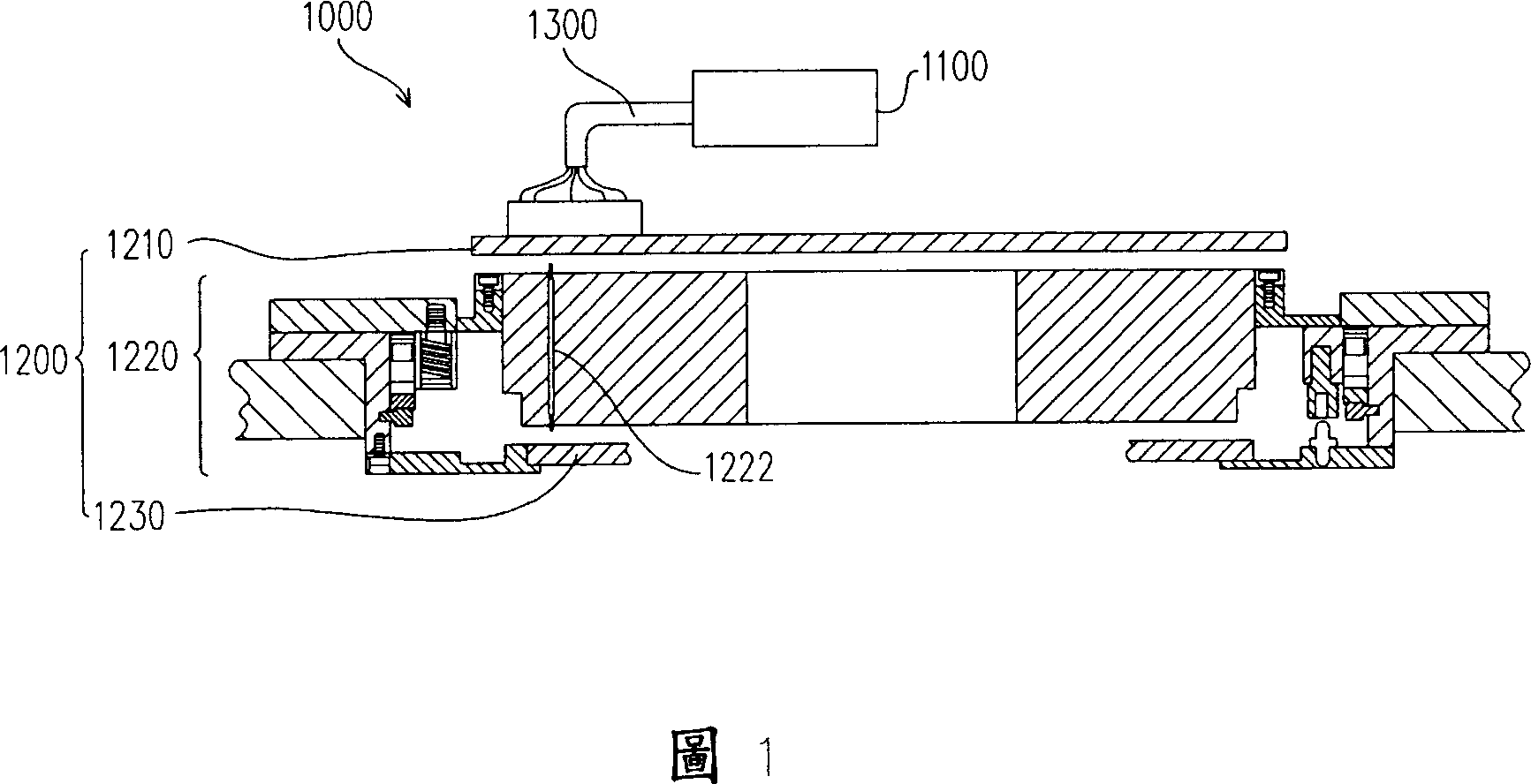

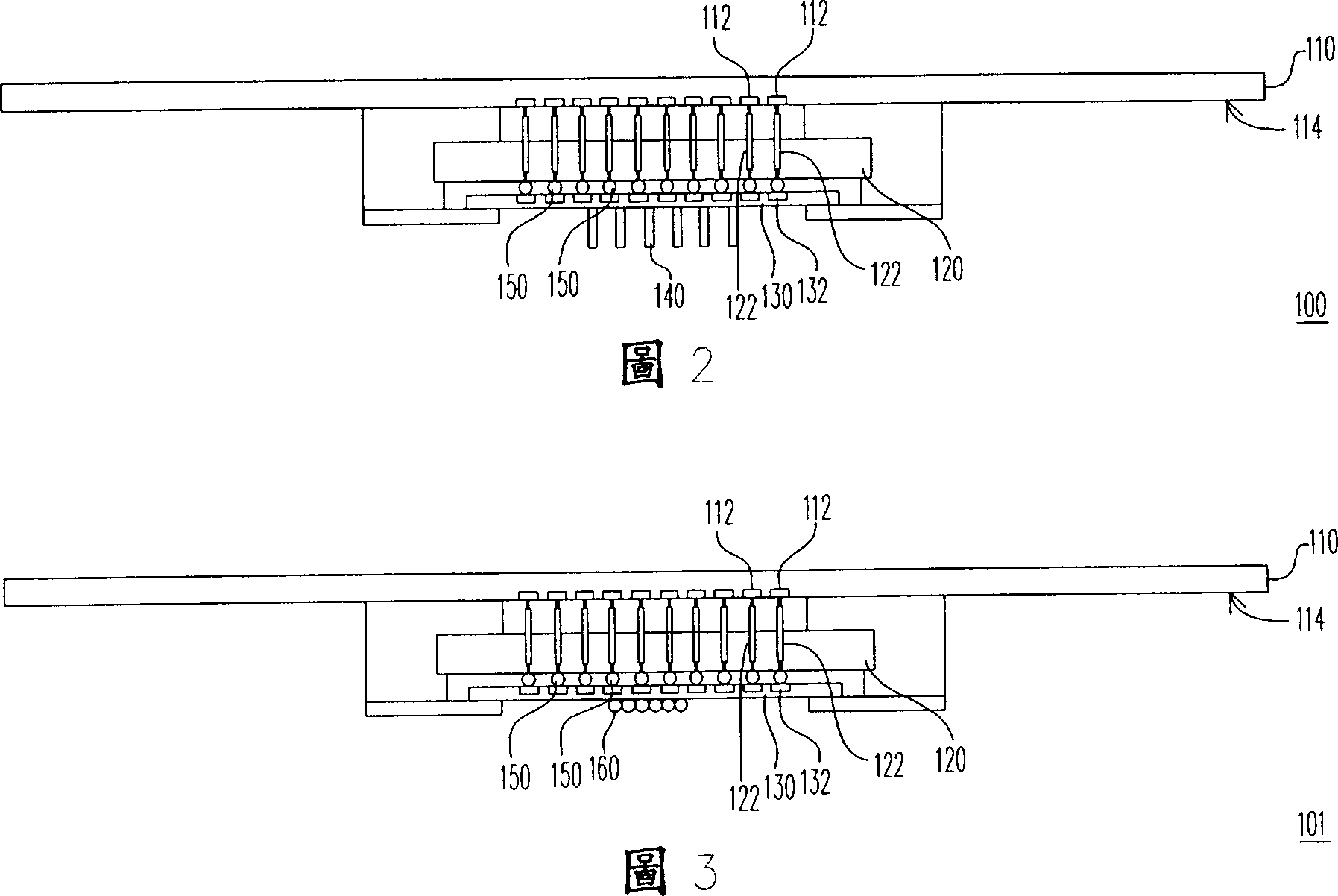

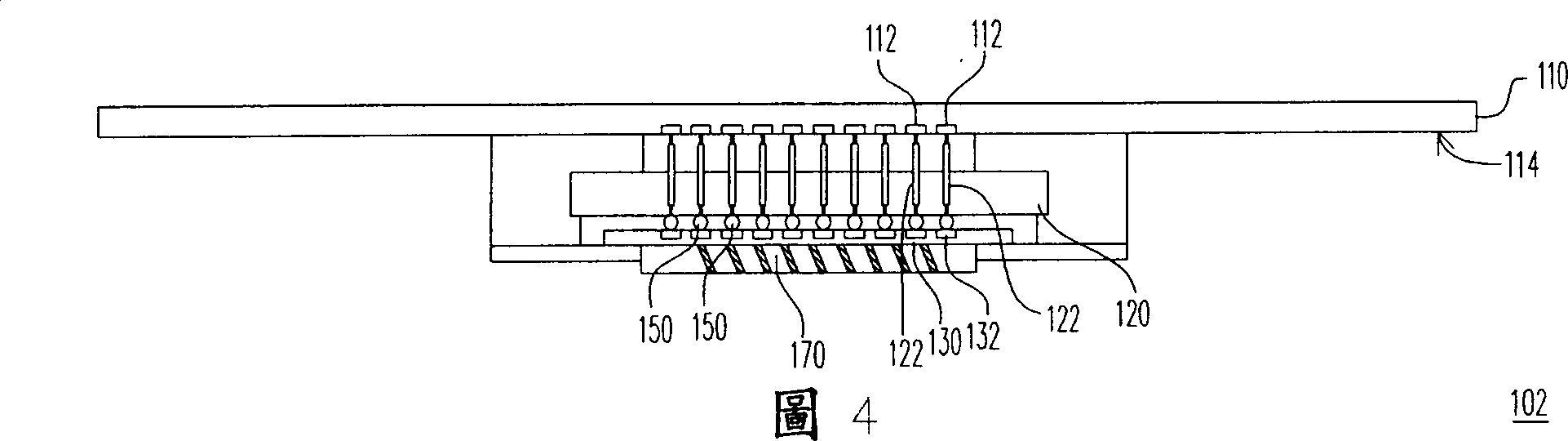

[0048] FIG. 2 is a schematic diagram of a wafer testing module according to an embodiment of the present invention. Referring to FIG. 2 , the chip test module 100 mainly includes a test load board 110 , a pod socket 120 , a substrate 130 and a plurality of probes 140 . The test load board 110 has a plurality of first contacts 112 , wherein the first contacts 112 are located on a surface 114 of the test load board 110 . The test load board 110 is, for example, a printed circuit board (PCB) or a circuit board manufactured by other types of processes, and its function is similar to the circuit board 1210 for electrically transmitting test signals of the chip test system 1100 in FIG. 1 . It is worth noting that the pogo pin socket 120 is configured on the test load board 110, and the pogo pin socket 120 is provided with a plurality of retractable pogo pins 122, which are used to replace the probe contact seat and complex Unique positioning mechanism and lifting self-locking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com