Retainer ring for CMP device, method of manufacturing the same, and CMP device

A manufacturing method and retaining ring technology, which is applied in the manufacture of tools, grinding devices, semiconductor/solid-state devices, etc., can solve the problems of not being able to adapt to the need for grinding, not being able to suppress time, and not being clear, etc., to achieve small surface roughness, The effect of reducing defective products and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

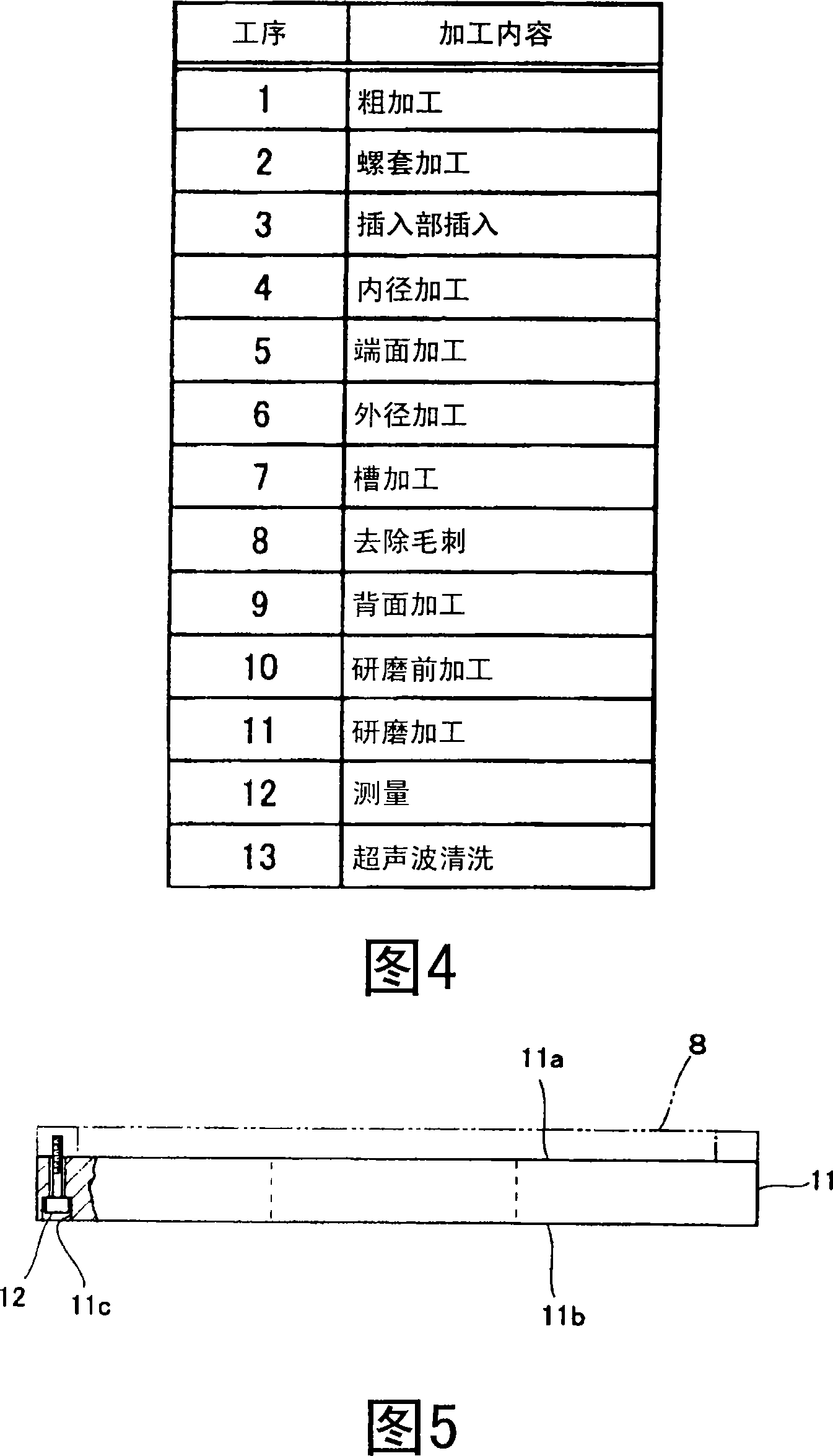

[0067] Hereinafter, the present invention will be described based on the illustrated embodiments.

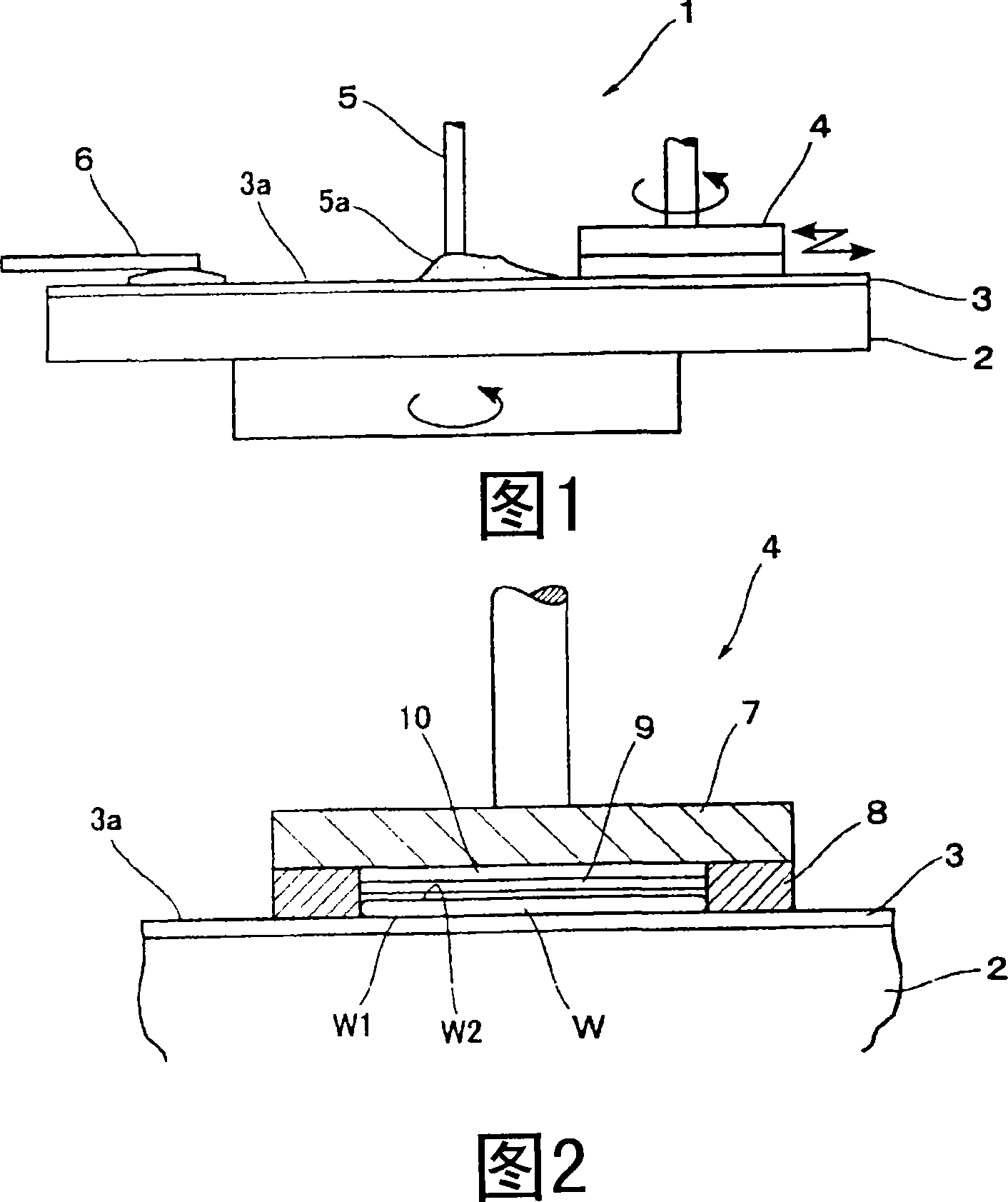

[0068] FIG. 1 is a front view showing a schematic configuration of a CMP apparatus 1 according to an embodiment of the present invention. This CMP apparatus 1 has the same structure as a widely used CMP apparatus except for a back-up ring 8 described later, and its detailed description is omitted here, but includes a rotatable grinding disc 2 and a The polishing pad 3 (fabric, etc.), the holding head 4, the slurry supply nozzle 5 (slurry supply mechanism), and the dresser 6 (shaping mechanism) are devices for performing chemical mechanical polishing W on the wafer W.

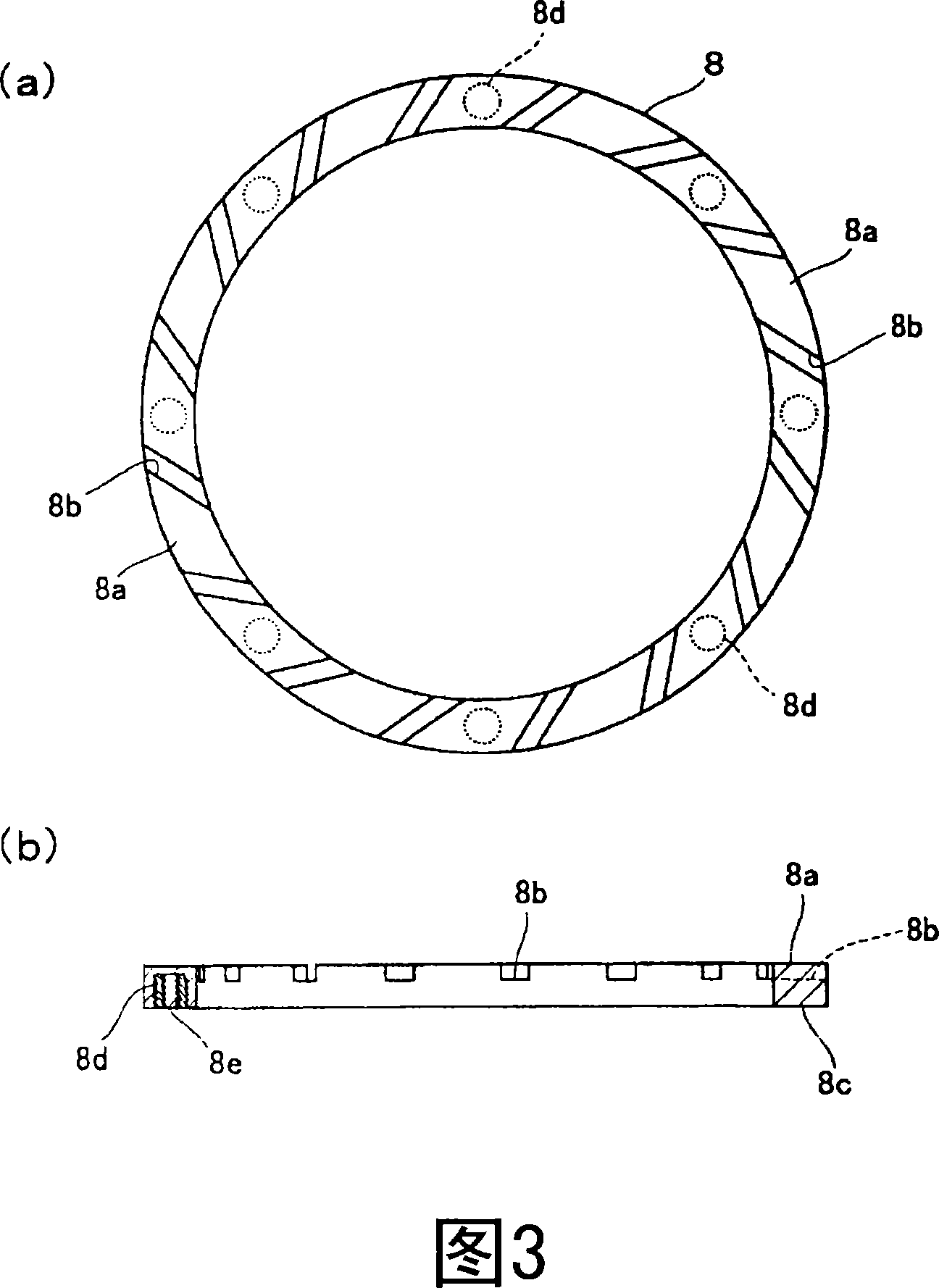

[0069] The holding head 4 holds the wafer W and presses the polished surface W1 to the polishing pad 3 , and can move on the polishing pad 3 while rotating (rotating). As shown in FIG. 2 , the holding head 4 includes a head main body 7 , a retaining ring 8 disposed under the head main body 7 , and an elastomer fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com