Device detecting magnetic conduction component defect based on magnetic striction torsion wave

A magnetostrictive and torsional wave technology, which is applied to the magnetic variables of materials, the use of acoustic wave emission technology for material analysis, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as inability to excite and receive torsional waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described in detail below in conjunction with the accompanying drawings.

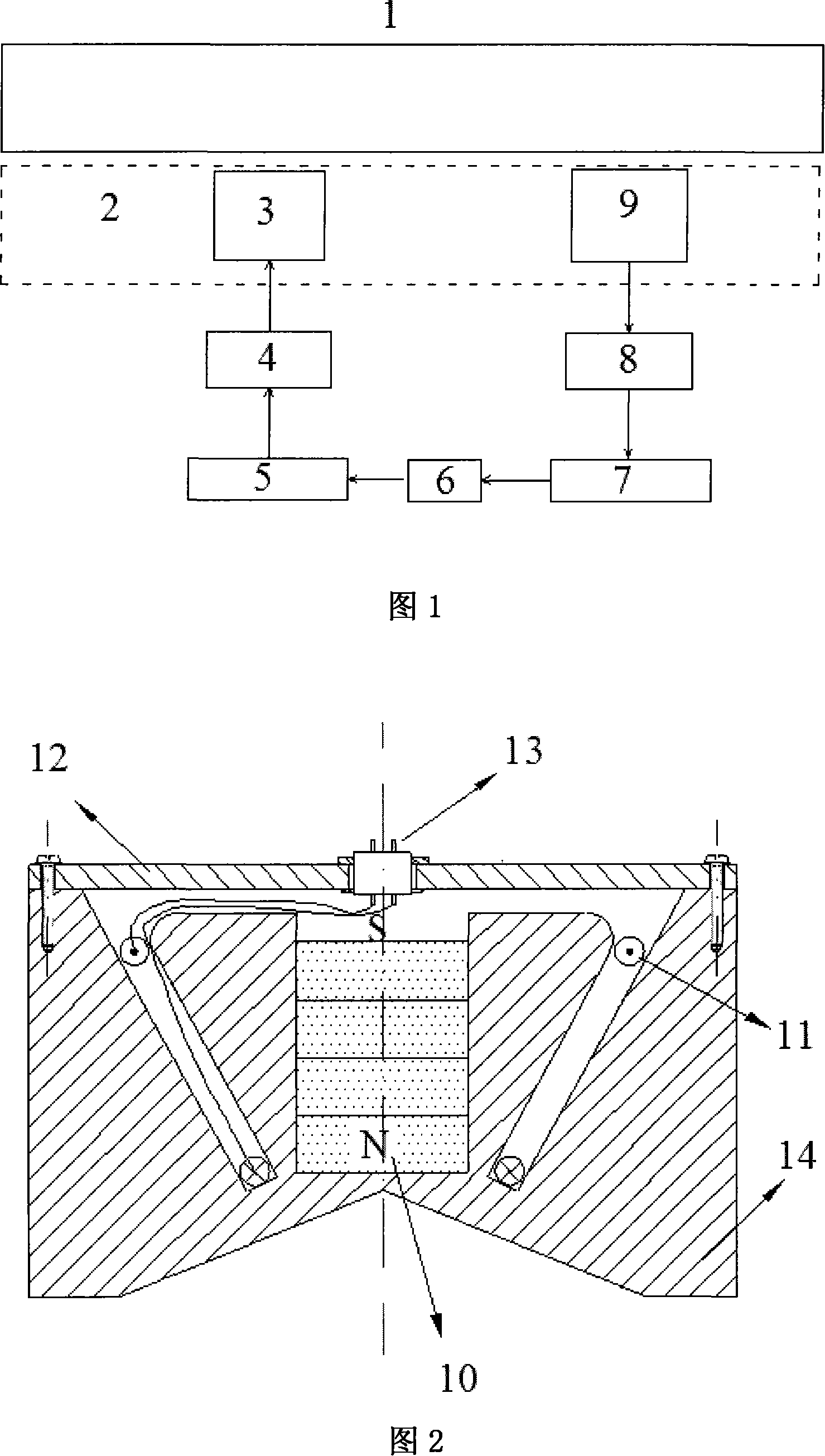

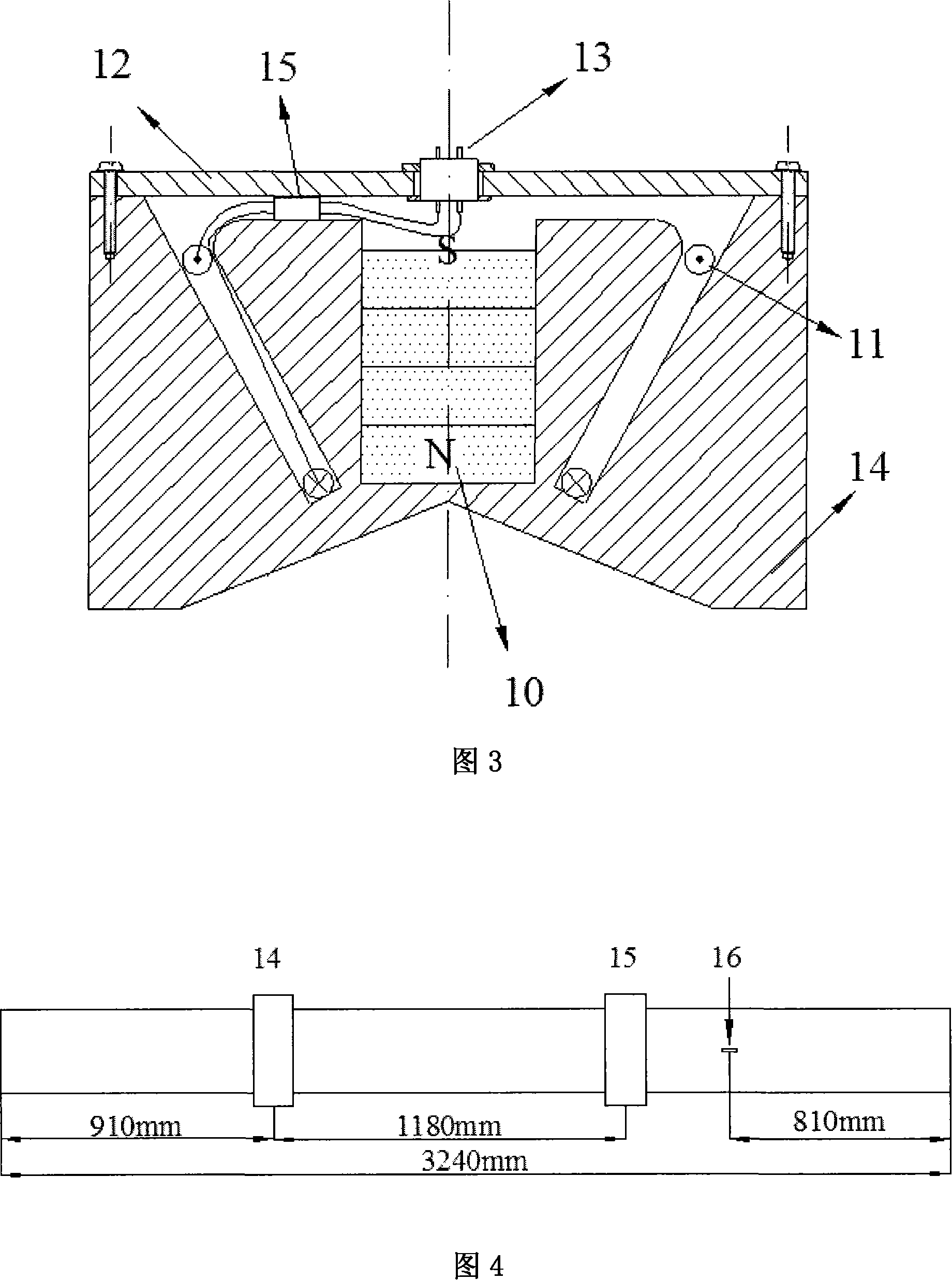

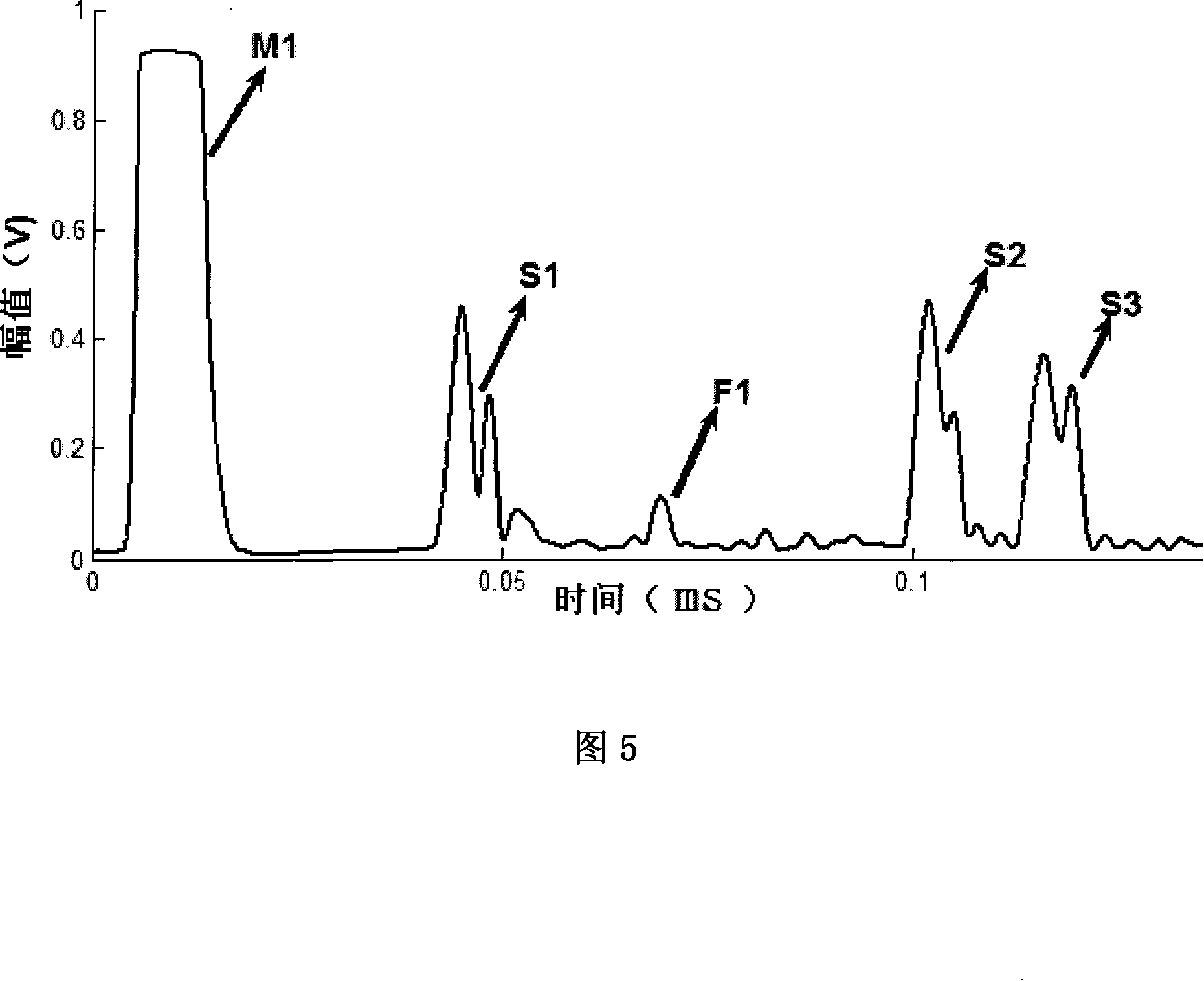

[0019] As shown in Figure 1, in the present invention, magnetostrictive torsional wave sensor 2 comprises excitation unit 3 and receiving unit 9, computer 6 is connected with the control terminal of pulse signal generator 5 by communication cable, the output terminal of pulse signal generator 5 Connect the input end of the power amplifier 4, the output end of the power amplifier 4 is connected to the excitation unit 3 through a high-frequency cable, the excitation unit 3 uses the magnetostrictive effect to excite the elastic wave of the torsional mode in the detected component 1, and the receiving unit 9 The elastic wave signal is converted into an electrical signal by utilizing the inverse magnetostrictive effect, the output end of the receiving unit 9 is connected to the input end of the signal preprocessor 8, and the output end of the signal preproce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com