Flash memory device

A technique of etching and stacking gates, which is applied in the field of manufacturing flash memory devices, and can solve problems such as reduced realizability and poor efficiency of flash memory devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

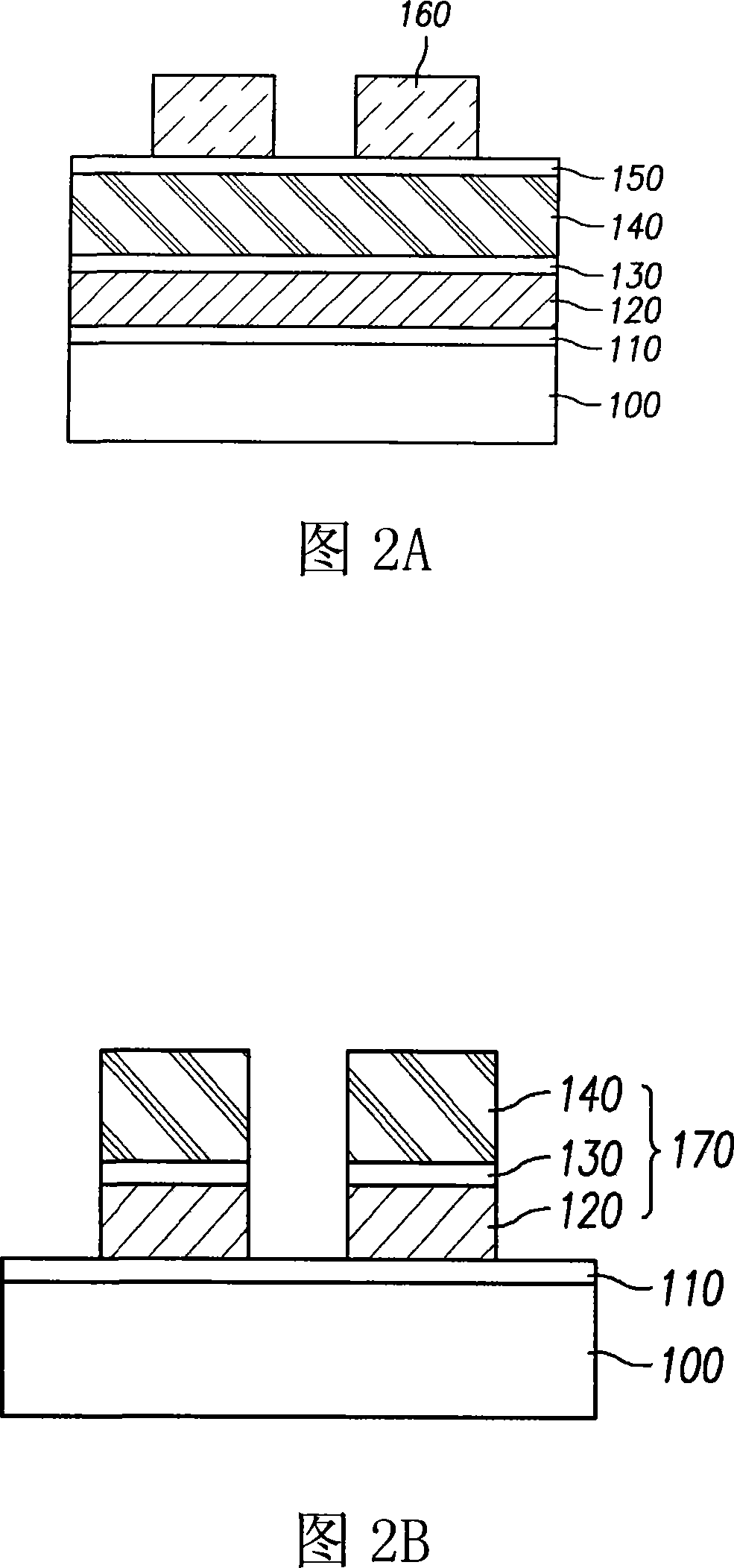

[0016] Referring to FIG. 2A, an oxide film 110, a floating gate polysilicon film 120, an oxide-nitride-oxide (ONO) film 130, a control gate polysilicon film 140, and a bottom anti-reflective film are sequentially stacked on a semiconductor substrate 100. Coating (BARC) 150. To form the stacked gate, a photoresist for KrF is coated with a thickness between approximately 4000 Ȧ and 5000 Ȧ.

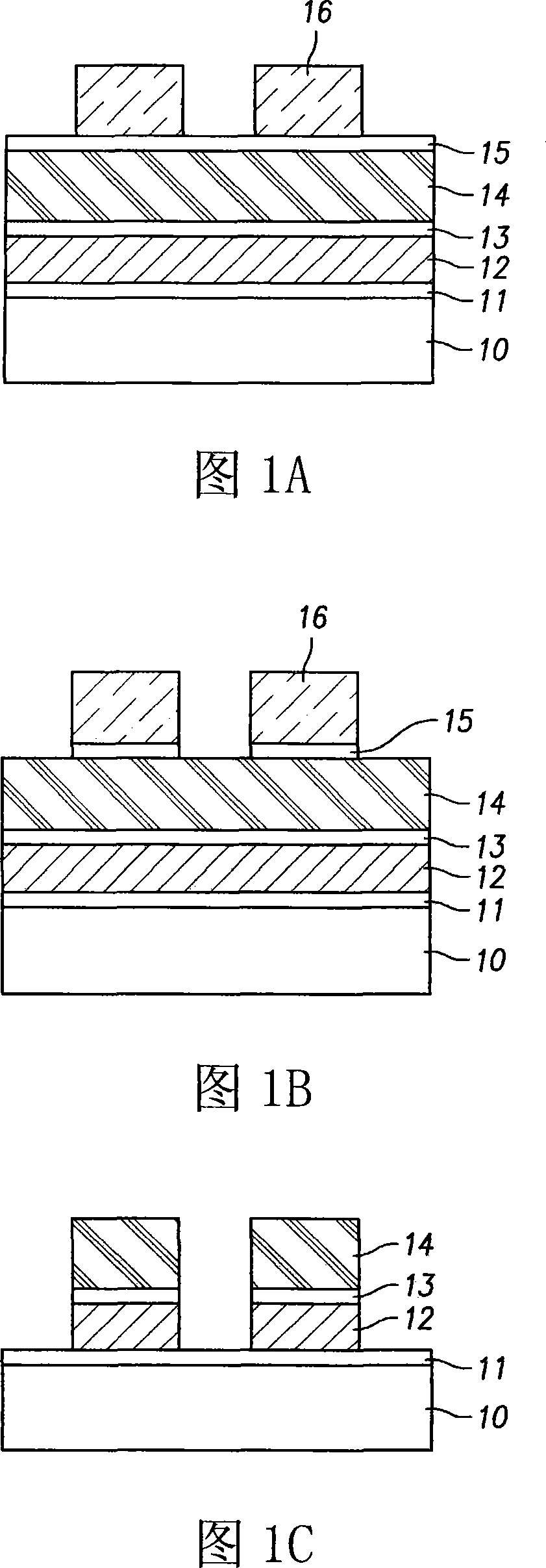

[0017] The photoresist for KrF is patterned to form a photoresist pattern 160 for KrF. After obtaining a depth of focus (DOF) margin in the exposure process, the BARC 150 and the stacked gate film including the floating gate polysilicon film 120, the ONO film 130, and the control gate polysilicon film 140 are etched together. . According to an embodiment, the etching method is different from the related art etching method which first etches the BARC 15 using the photoresist pattern 16 (as shown in FIG. 1B ), and then etches the floating gate polysilicon film 12, the ONO film 13 and Contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com