Disposable composite shoe cover material and its preparation method

A disposable and shoe cover technology, which is applied in the direction of chemical instruments and methods, footwear, synthetic resin layered products, etc., can solve the problems of poor air permeability, poor dust resistance, indoor environmental pollution, etc., and achieve short time consumption and improved use The effect of simple function and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

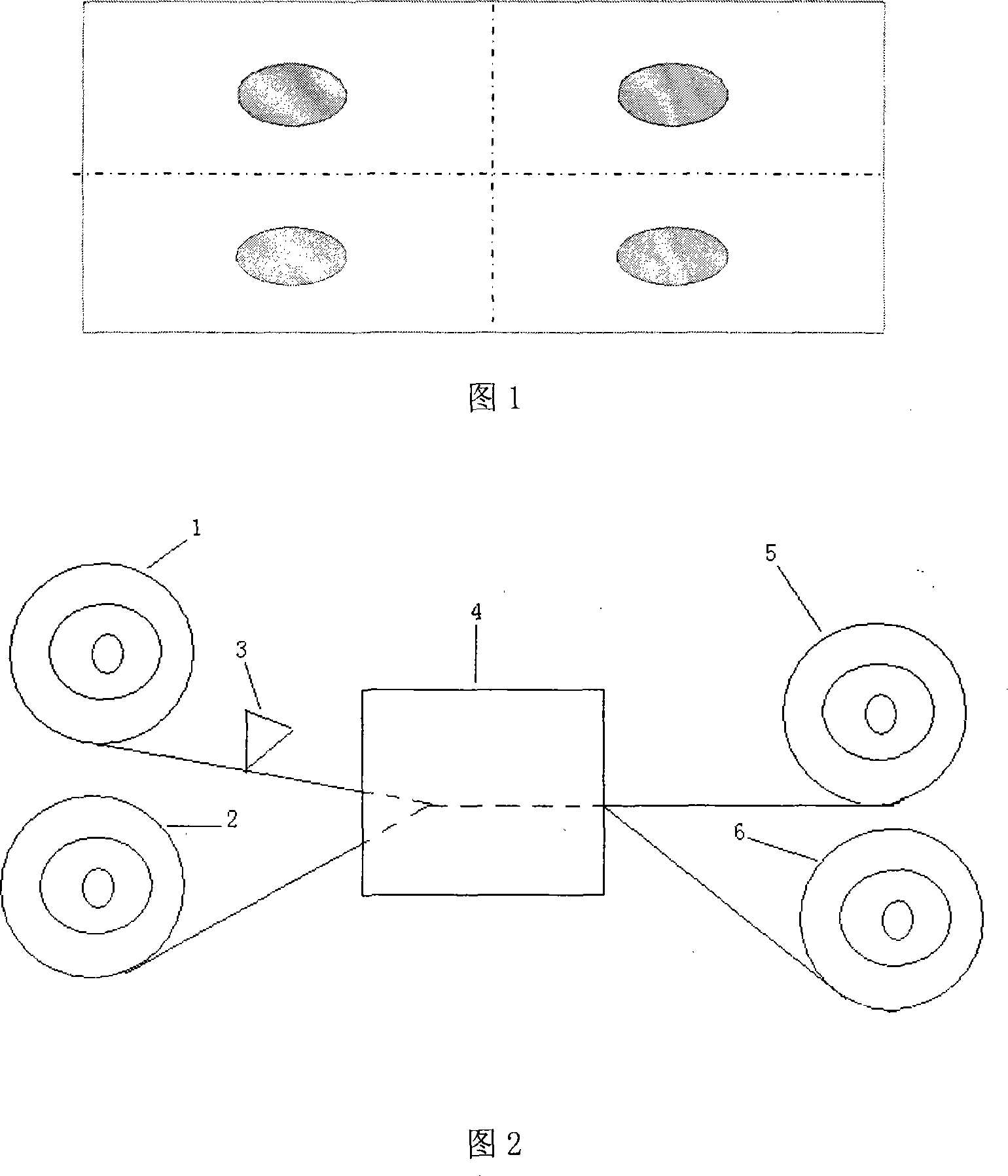

[0022] Accompanying drawing 1 is the structural representation of disposable composite shoe cover material, and shaded part is sole material, is formed by plastic film and non-woven fabric compound, and it can be the circular shape that sole needs, ellipse or other irregular shape; The rest are nonwovens. Cut the composite material along the dotted line in the figure, and then sew rubber bands around it to make a disposable composite shoe cover whose bottom is made of plastic film and non-woven fabric, and the upper is made of non-woven fabric.

Embodiment 2

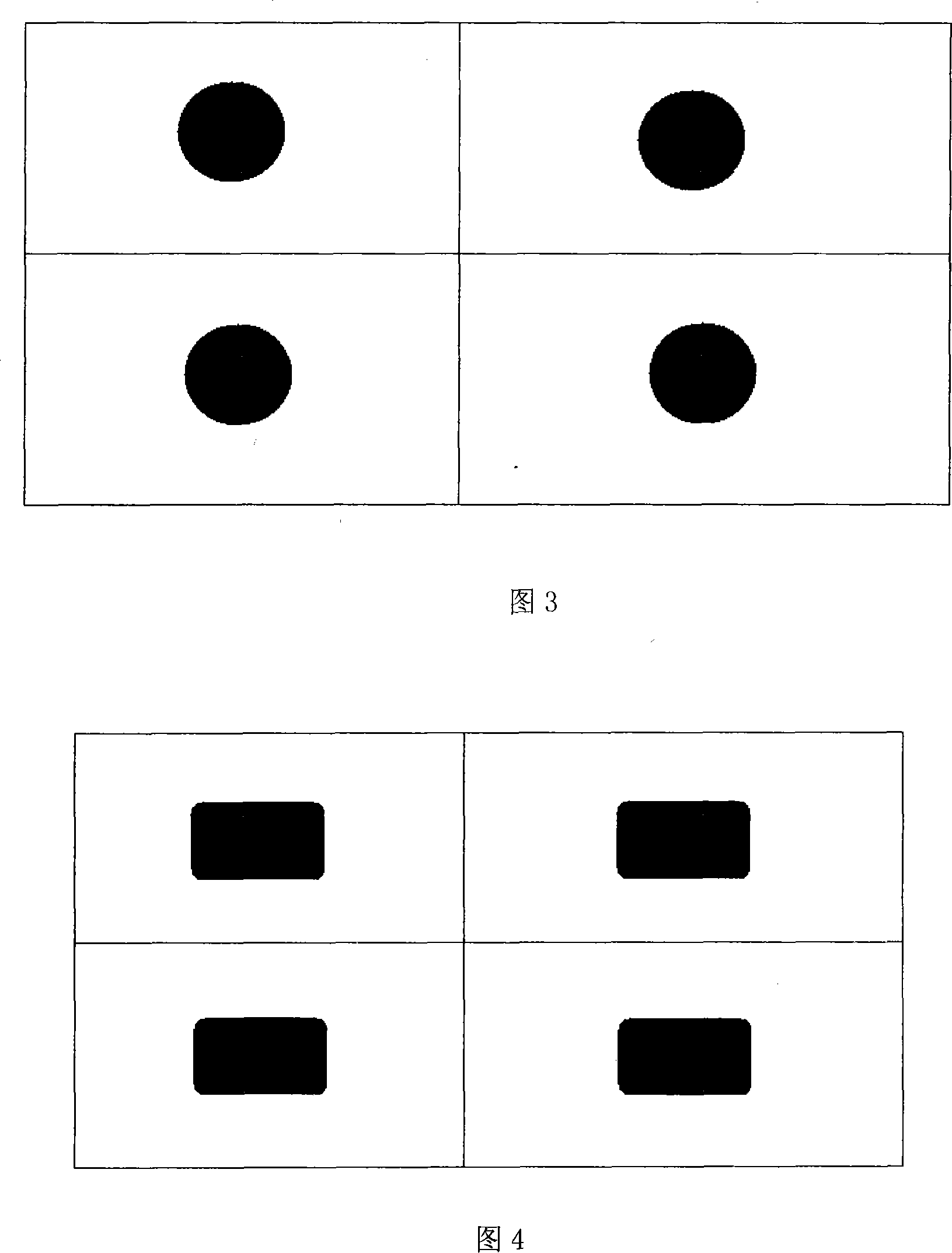

[0024] The polypropylene film that width is 1m is unrolled with the speed of 5m / min, is cut into two circular composite film soles through two circular cutters of 0.08m at the distance of each 0.25m from two edges of the film. Adjust the falling speed of the cutter so that the distance between the front and rear two film soles is 0.5m, and the structure of the gained film is as shown in Figure 3.

[0025] The polypropylene spun-bonded non-woven fabric with a width of 1m enters the composite device at a speed of 5m / min. In the ultrasonic bonding composite device, the circular plastic film and the non-woven fabric are composited and wound up to become a one-time composite. For the shoe cover material, the excess plastic film is peeled off and rolled up as scraps.

Embodiment 3

[0027] Unwind a polypropylene film with a width of 1m at a speed of 20m / min, and cut it into an elliptical composite film at a distance of 0.25m from the two edges of the film through an oval cutter with a major axis of 0.2m and a focal length of 0.1m soles. Adjust the falling speed of the cutter so that the distance between the front and back two film soles is 0.5m, and the structure of the gained film is as shown in Figure 1.

[0028] The polypropylene spunbonded nonwoven fabric with a width of 1m enters the composite device at a speed of 20m / min. In the ultrasonic bonding composite device, the oval plastic film and the nonwoven fabric are composited and wound up to become a one-time composite. For the shoe cover material, the excess plastic film is peeled off and rolled up as scraps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com