Shearing machine for metal ornamental chain

A shearing machine and decorative chain technology, applied in the direction of shearing devices, metal processing equipment, shearing machine equipment, etc., can solve the problems of low efficiency, time-consuming labor intensity, low measurement accuracy, etc., and achieve simple mechanical structure, High production efficiency and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

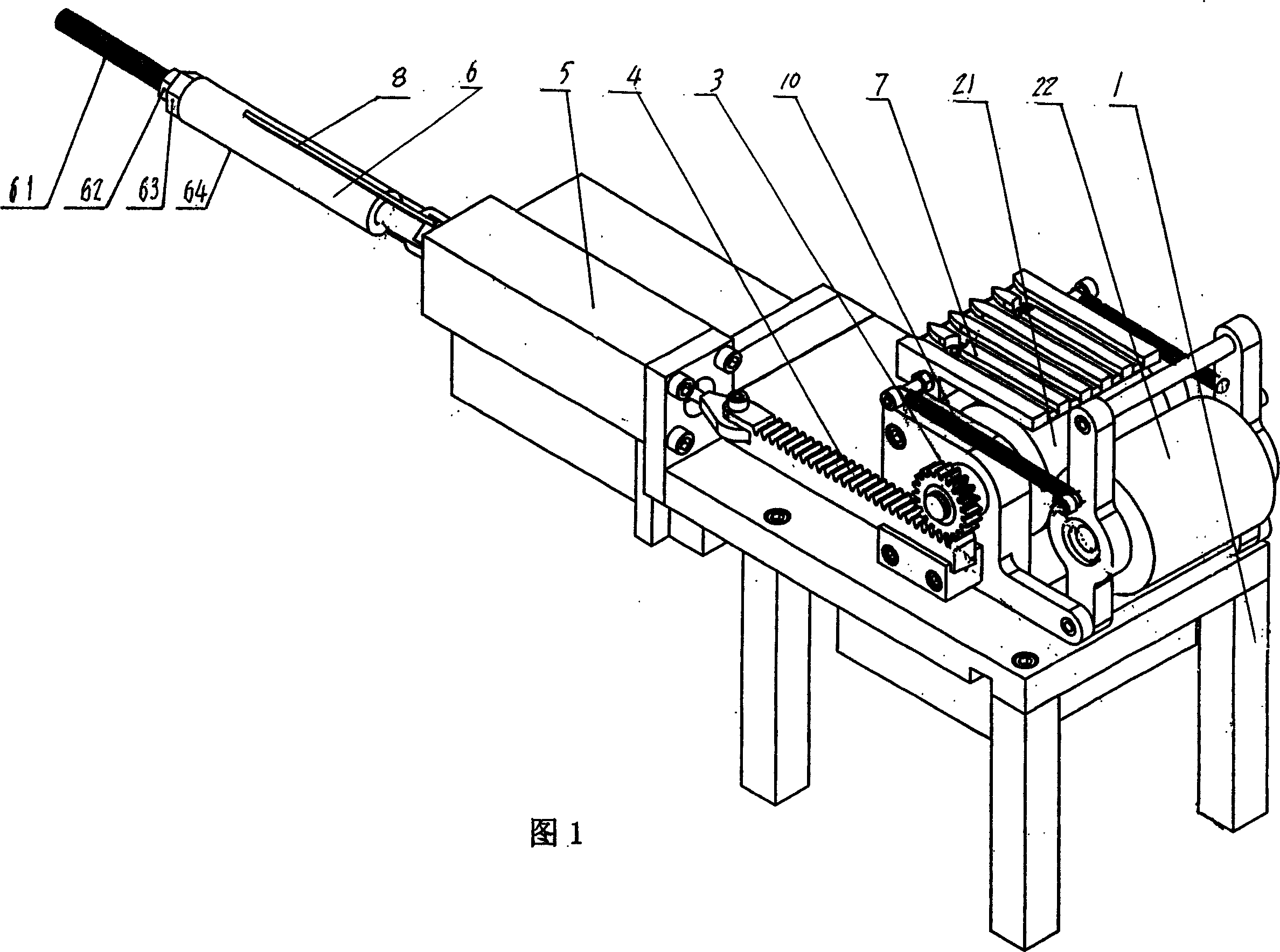

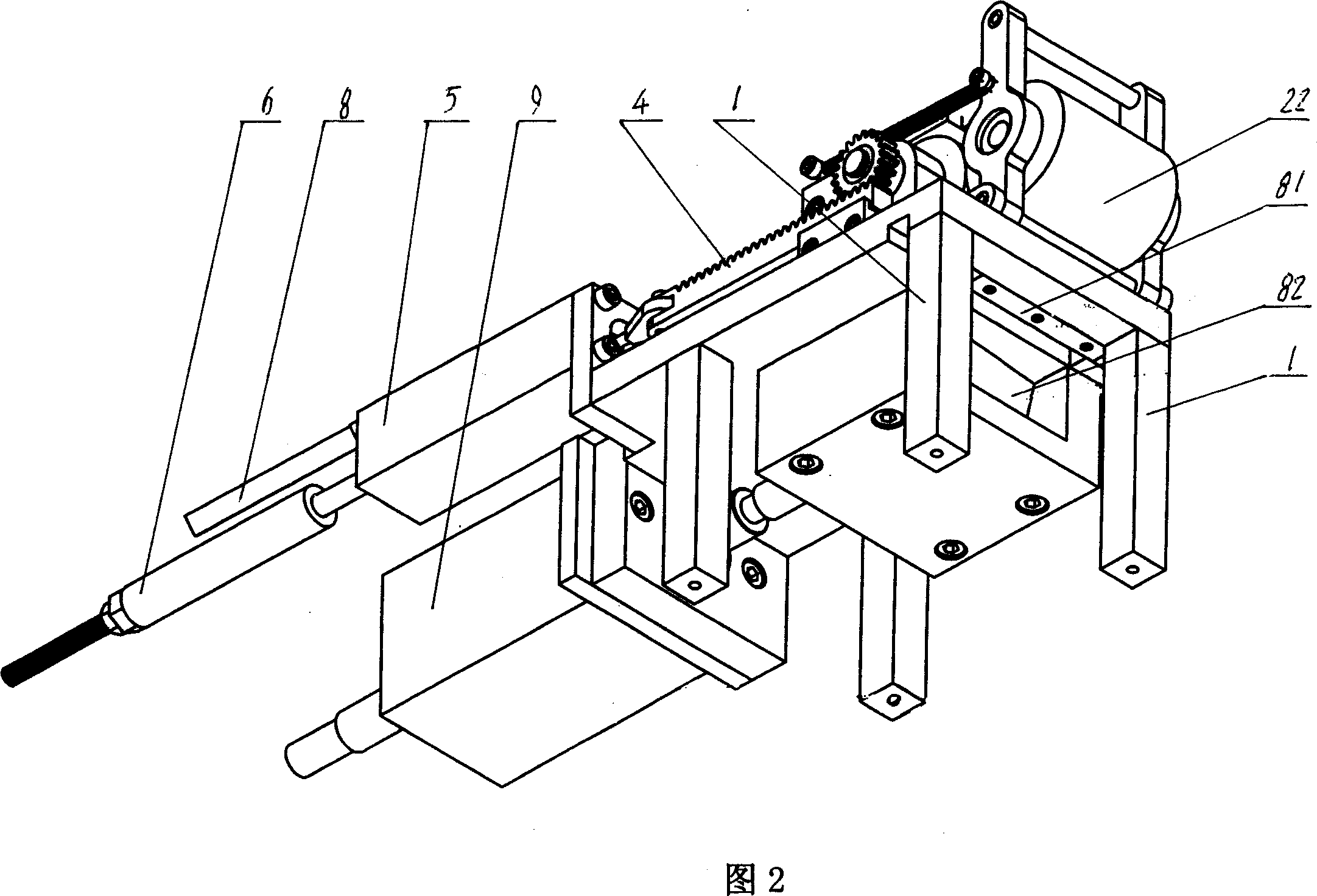

[0016] As shown in Figure 1, a metal decorative chain shearing machine is equipped with a pair of feeding rubber wheels 21 and 22 in contact with each other on the frame 1, and the pressing force between the two feeding rubber wheels can be adjusted by a spring, or can be adjusted by a Adjustment screw adjustment, the present invention adopts spring 10 adjustment. The active feeding rubber wheel 21 of the feeding rubber wheel adopts a one-way bearing or an overrunning clutch, and the present invention adopts a one-way bearing. Gear 3 is housed on the driving rubber wheel, cooperates with rack 4, and rack is connected with the piston shaft of transmission cylinder 5. Length adjuster 6 is housed on the extension body of piston tail shaft, and length adjuster is the adjustment screw rod 61 that is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com