Non-clinker brick and preparation method thereof

A technology of non-fired bricks and stone powder, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A non-fired brick, which is mainly made of the following materials in parts by weight: 50 parts of coarse stone chips, 47 parts of stone powder, 2 parts of cement, and 1 part of polypropylene engineering fiber, wherein the coarse stone chips The particle size is 18mm-26mm, and the particle size of stone powder is less than 0.15mm.

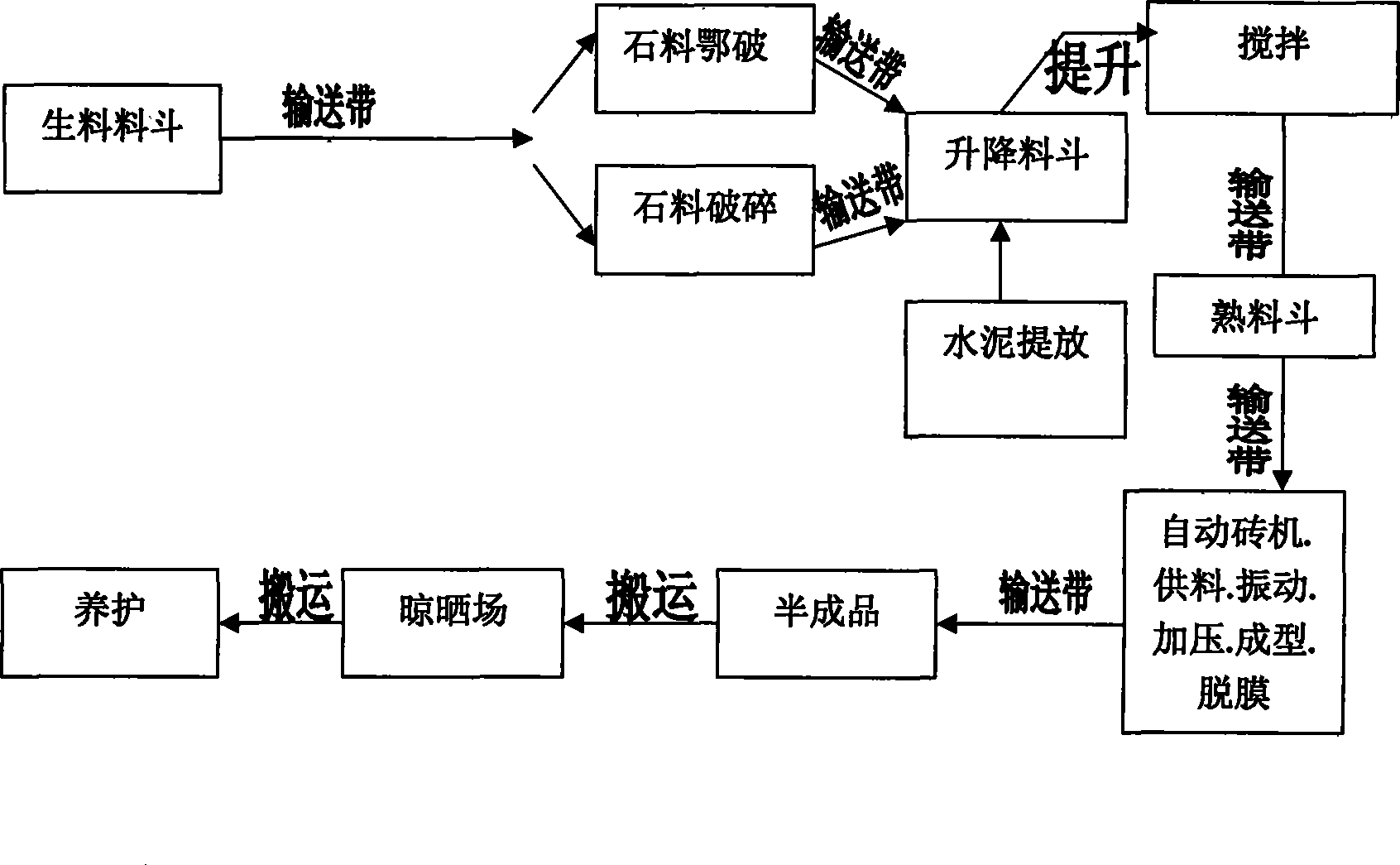

[0019] As shown in the accompanying drawings, the manufacturing method of the non-fired brick comprises the following steps:

[0020] A. The stone in the raw material hopper is sent to the stone jaw crusher and the stone crushing device respectively through the conveyor belt. In the stone jaw crusher, the stone is processed into powder, and the particle size of the stone powder is less than 0.15mm. The stone is processed into coarse stone chips, and the particle size of the coarse stone chips is 18mm-26mm;

[0021] B. Send the crushed stone and stone powder into the lifting hopper through two conveyor belts at the same time in step A, where...

Embodiment 2

[0033] A non-fired brick, which is mainly made of the following materials in parts by weight: 70 parts of coarse stone chips, 20 parts of stone powder, 2 parts of cement, and 8 parts of polypropylene engineering fibers, wherein the coarse stone chips The particle size is 18mm-26mm, and the particle size of stone powder is less than 0.15mm.

[0034] The manufacturing method of the non-sintered bricks is only that the weight of raw materials put in is according to the ratio of the raw materials of the non-sintered bricks in this embodiment, and the rest of the process steps are carried out according to the steps of the first embodiment.

Embodiment 3

[0036] A non-fired brick, which is mainly made of the following materials in parts by weight: 30 parts of coarse stone chips, 60 parts of stone powder, 8 parts of cement, and 2 parts of polypropylene engineering fibers, wherein the coarse stone chips The particle size is 18mm-26mm, and the particle size of stone powder is less than 0.15mm.

[0037] The manufacturing method of the non-sintered bricks is only that the weight of raw materials put in is according to the ratio of the raw materials of the non-sintered bricks in this embodiment, and the rest of the process steps are carried out according to the steps of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com