Drying room for tentering boarding machine

A tenter setting machine and drying room technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of poor fabric quality, poor effect, low temperature, etc., achieve good effect and reduce temperature Gradient distribution, uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

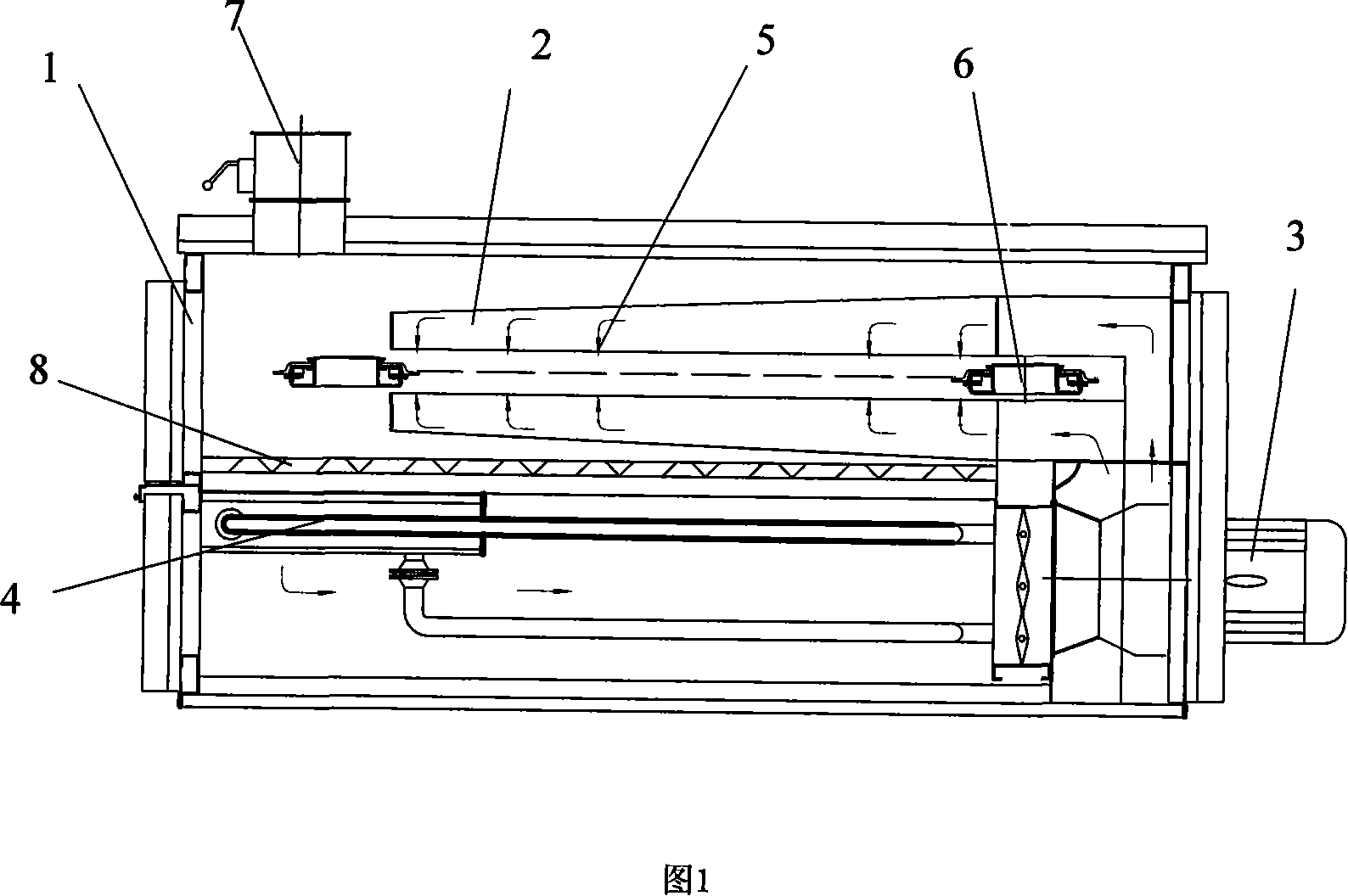

[0015] The present invention will be described in detail below with reference to the accompanying drawings. As shown in Figure 1, it includes a drying room box 1, a heating device composed of a spray pipe 2, a circulating fan 3, and a radiator 4, and a conveyor belt is arranged in the drying room box. 6. The air blowing pipe 2 includes an upper air blowing pipe and a lower air blowing pipe. The air blowing nozzles 5 are processed on the air blowing pipes, and the air blowing nozzles 5 on the two air blowing pipes are facing the conveyor belt 6 and arranged oppositely. An exhaust port 7 is also provided at the upper end of the drying room box 1, and a layer of filter screen 8 is also provided in the drying room box 1, and the filter screen 8 is located at the lower end of the lower air blowing pipe.

[0016] The heat transfer medium in the radiator 4 is oil, and water can also be selected. When in use, connect the cloth to the transmission belt 6, and the radiator 4 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com