A fuel cell stack with cross-cocurrent-convection comprehensive optimization characteristics

A fuel cell stack and battery unit technology, applied in fuel cells, fuel cell groups, circuits, etc., can solve the problems of reducing fluid distribution quality, unfavorable stack temperature, temperature rise, etc., and achieve the effect required by simple component processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

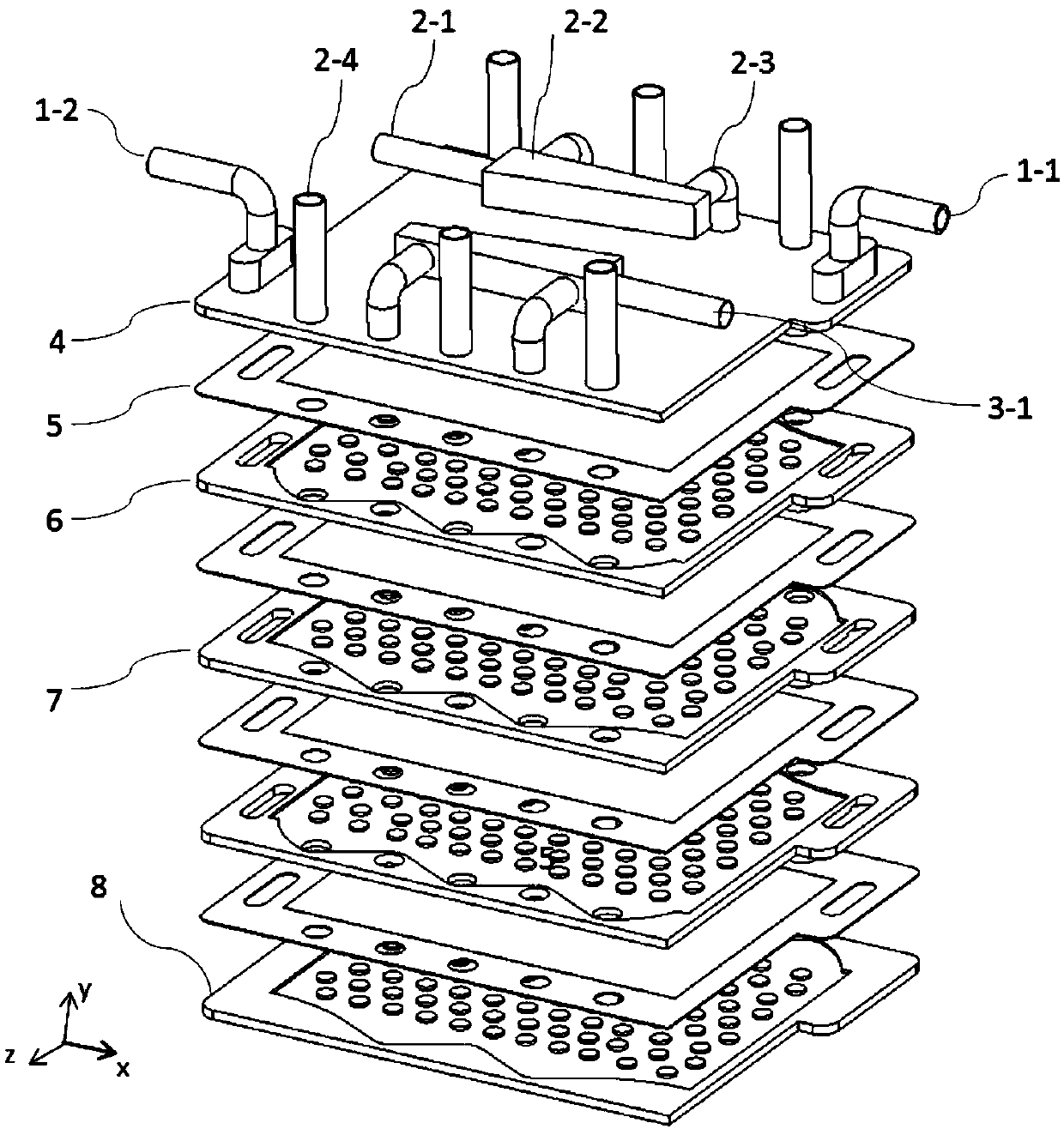

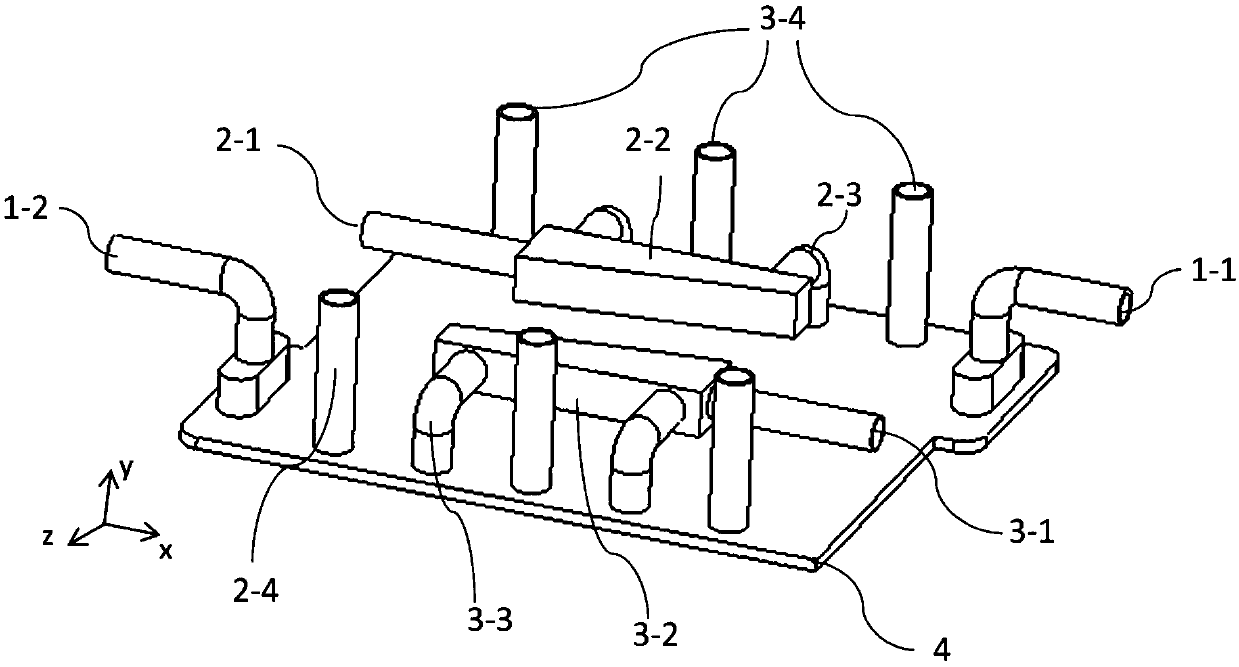

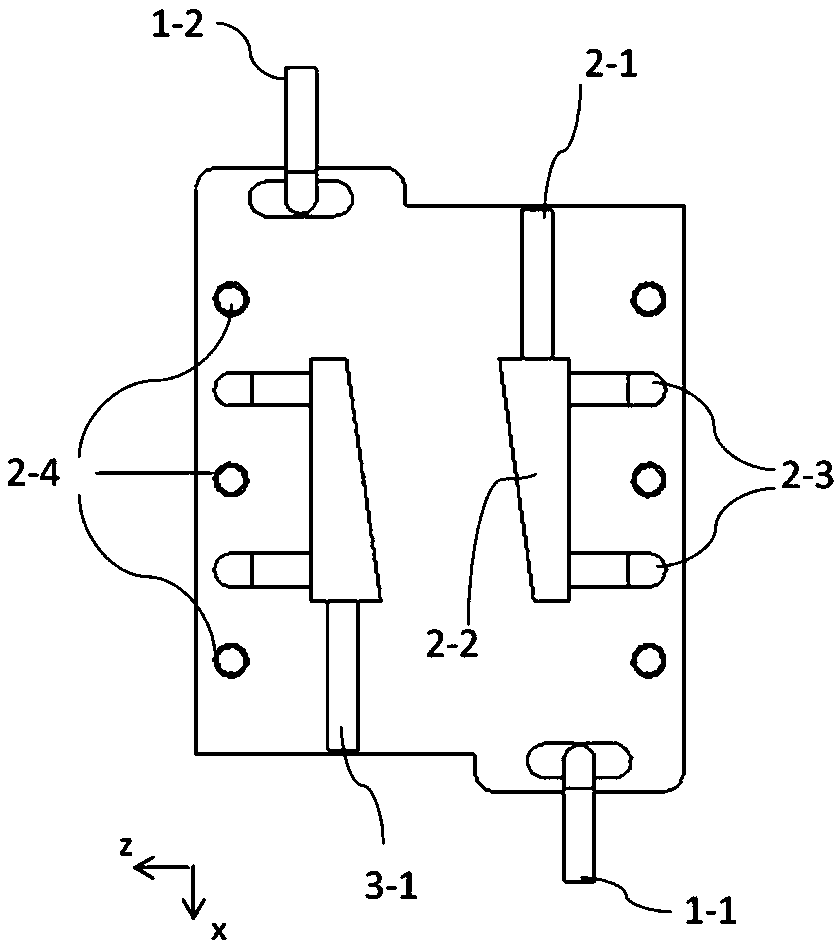

[0031] See figure 1 and figure 2 As shown, the present invention discloses a fuel cell stack with cross-cocurrent-convection integrated optimization features, including a top cover 4, a bottom cover 8, and a plurality of plate-shaped SOFCs stacked between the top cover 4 and the bottom cover 8. Battery unit 5. A connecting piece is sandwiched between the two adjacent SOFC battery cells 5, wherein the connecting piece is divided into an odd layer connecting piece 6 and an even layer connecting piece according to the odd and even numbers counted from top to bottom. 7.

[0032] The top cover 4 is provided with a fuel outlet main pipe 1-2, a fuel inlet main pipe 1-1, a first air flow channel inlet 2-1, and a first trapezoidal distributor 2-2 connected to the first air flow channel inlet , The first air flow path inlet main pipe 2-3, the first air flow path outlet tail gas main pipe 2-4, the second air flow path inlet 3-1, the second trapezoidal distributor connected to the second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com