Liquid tank vibration damper

A liquid storage tank and shock absorber technology, which is applied in the field of liquid storage tank shock absorbers, can solve problems such as increased vibration of compressors, and achieve the effect of reducing vibration and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

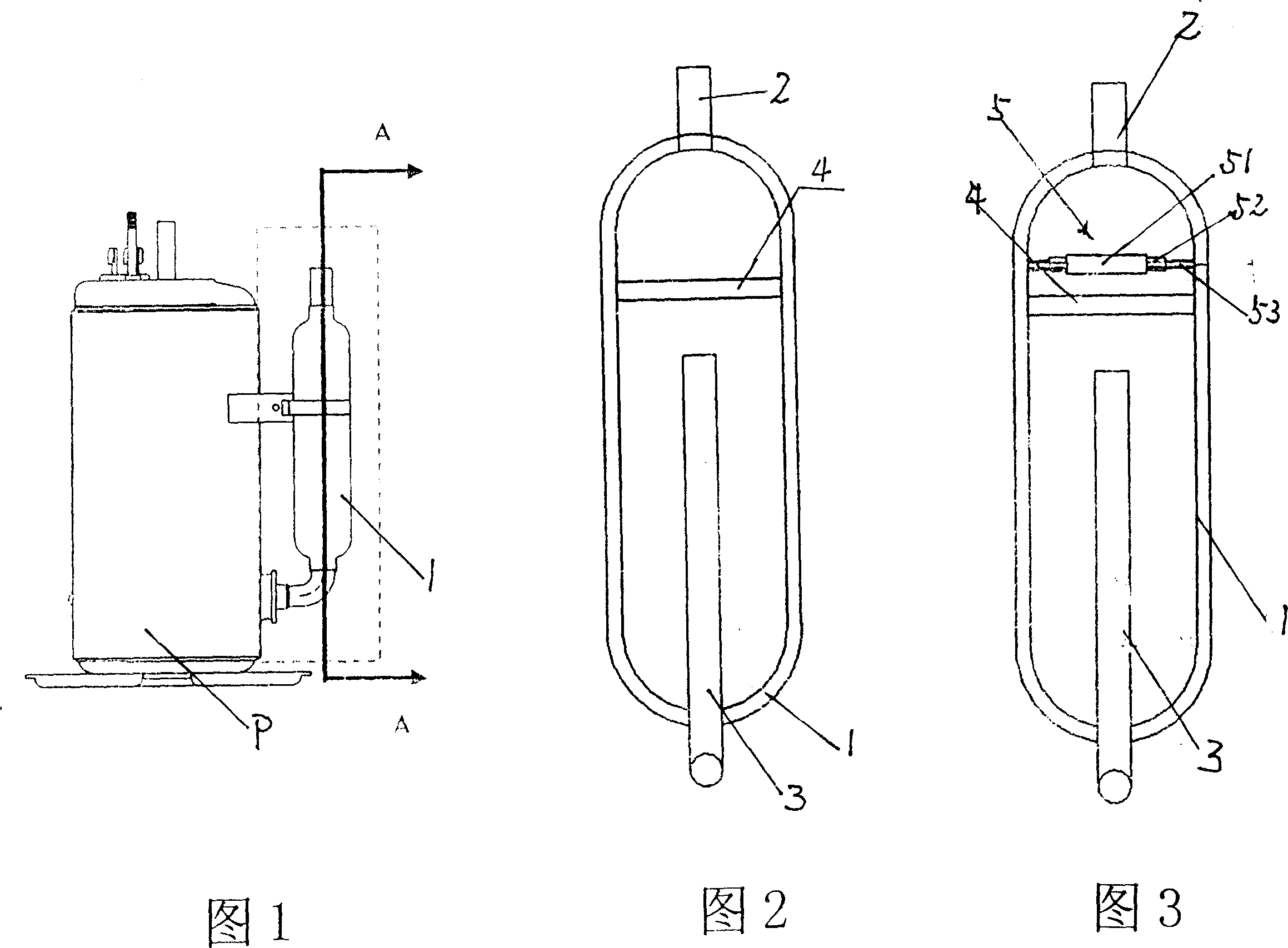

[0020] As shown in FIG. 2 , the existing liquid storage tank has no damping device, so the liquid storage tank 1 vibrates together under the influence of the compressor P connected thereto. And the liquid storage tank 1 shown in Figure 3 is equipped with the shock absorber 5 that first embodiment is made of mass block 51, support bar 52, damping 53, because the vibration of the shock absorber 5 that liquid storage tank 1 is housed The frequency is much lower than the vibration frequency transmitted by the compressor to the liquid storage tank 1, and cannot vibrate synchronously, and consumes energy during the vibration, so the amplitude of the vibration can be reduced, thereby reducing the noise.

[0021] The above are only preferred embodiments of the present invention, and are not intended to limit the present invention in any form. Any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com