Plunger pump-based transport robot

A robot and plunger pump technology, applied in the field of robotics, can solve problems such as large impact on the road surface, unstable robot movement, and untimely turning of the robot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

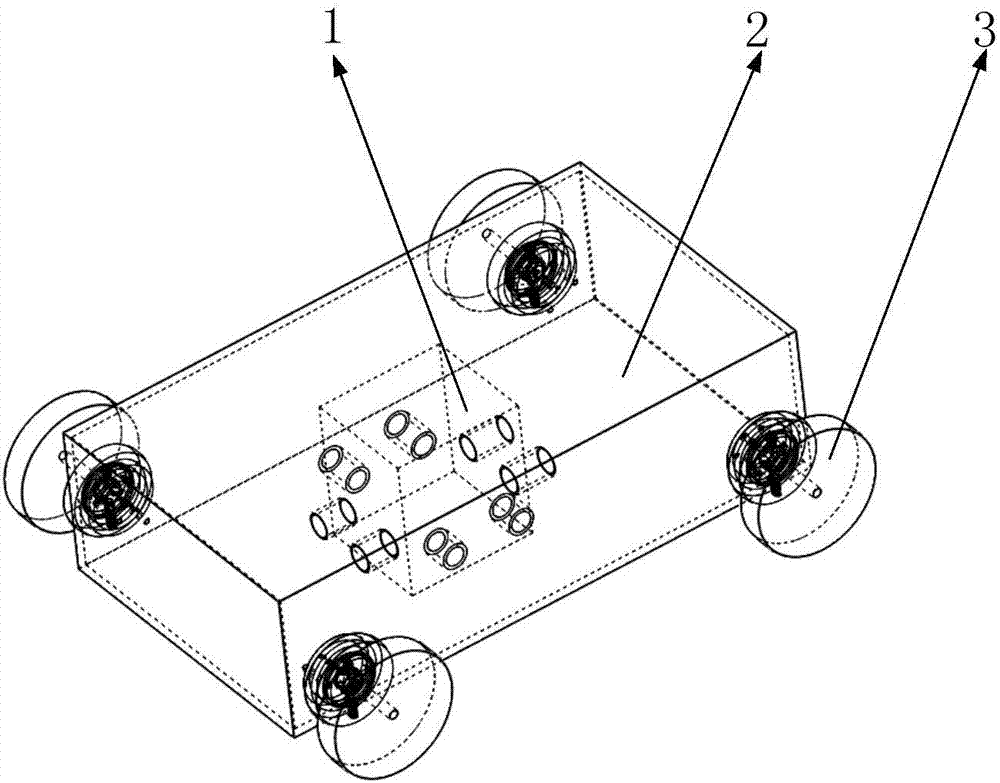

[0030] Such as figure 1 As shown, it includes a driving device 1, a vehicle body 2, and a driving wheel unit 3, wherein the driving device 1 is installed on the bottom surface of the vehicle body 2; And the two driving wheel units 3 on the same side are located at both ends of the vehicle body 2 .

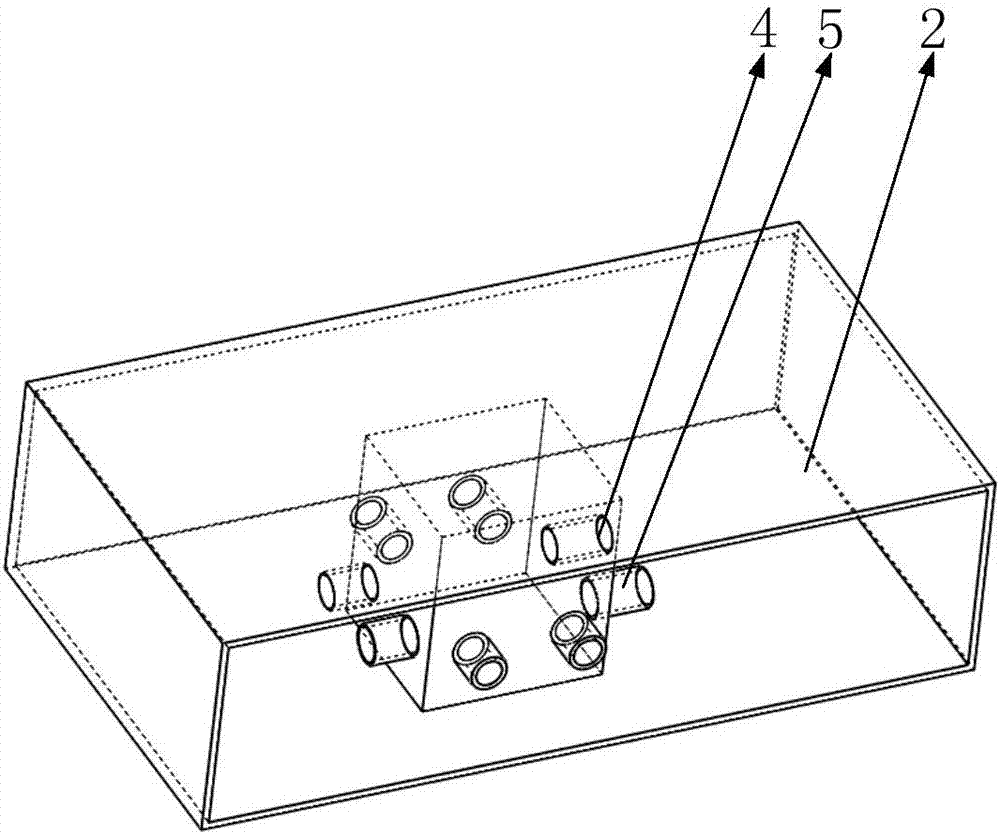

[0031] Such as figure 1 , 2 As shown, the above-mentioned drive device 1 includes a motor, a first hydraulic port 4, a second hydraulic port 5, an oil pump, a control chip, and an oil tank, wherein one first hydraulic port 4 and one second hydraulic port 5 form a group, and the four groups are all Installed on the outer wall of the driving device 1, and all cooperate with the oil pump and the oil tank.

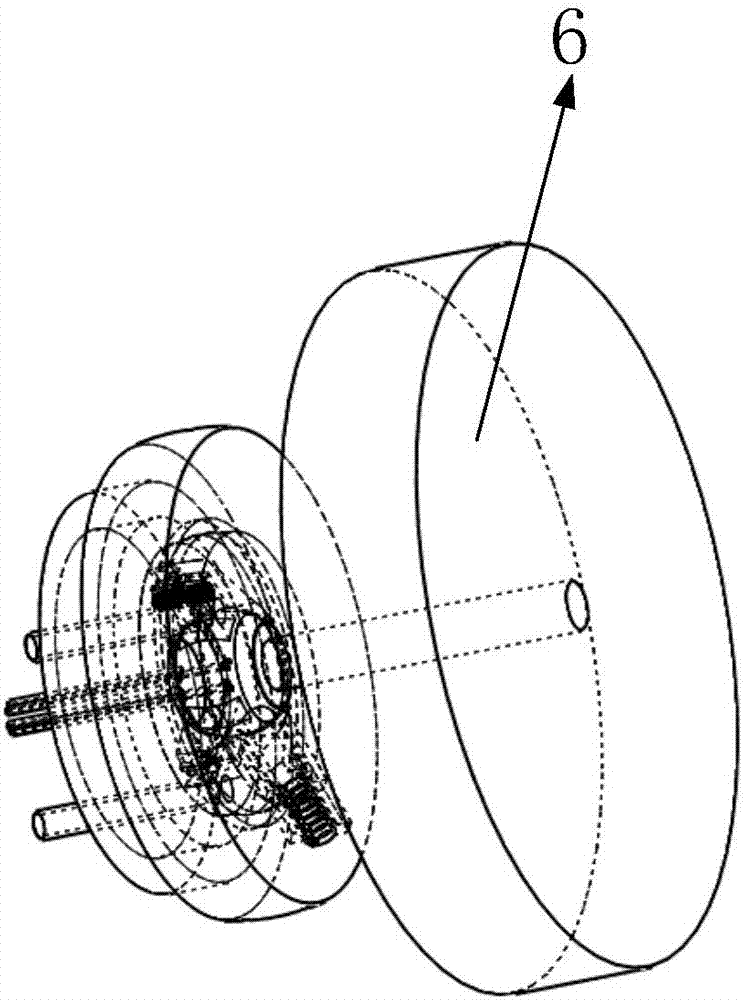

[0032] Such as image 3 As shown, the above-mentioned drive wheel unit 3 includes a spherical cavity 42, a wheel 6, a third hydraulic pipe 7, a fourth hydraulic pipe 8, a fifth hydraulic pipe 9, a seventh oil passage 50, an eighth oil passage 51, and a ninth oil passage. 52. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com