High-altitude infrared imaging method based on multi-element surface array splicing

An infrared imaging and area array technology, which is used in radiation pyrometry, image enhancement, image data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

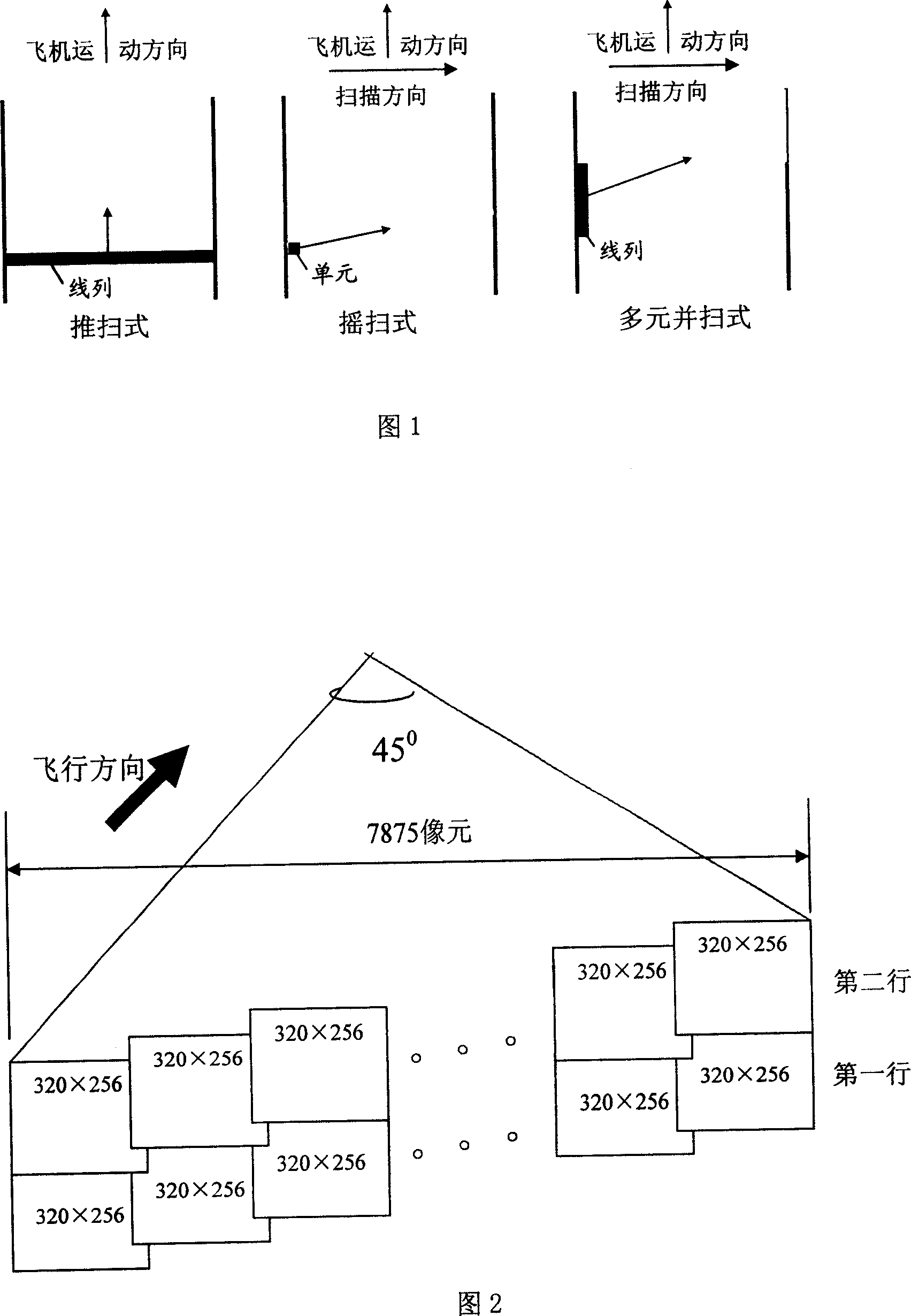

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

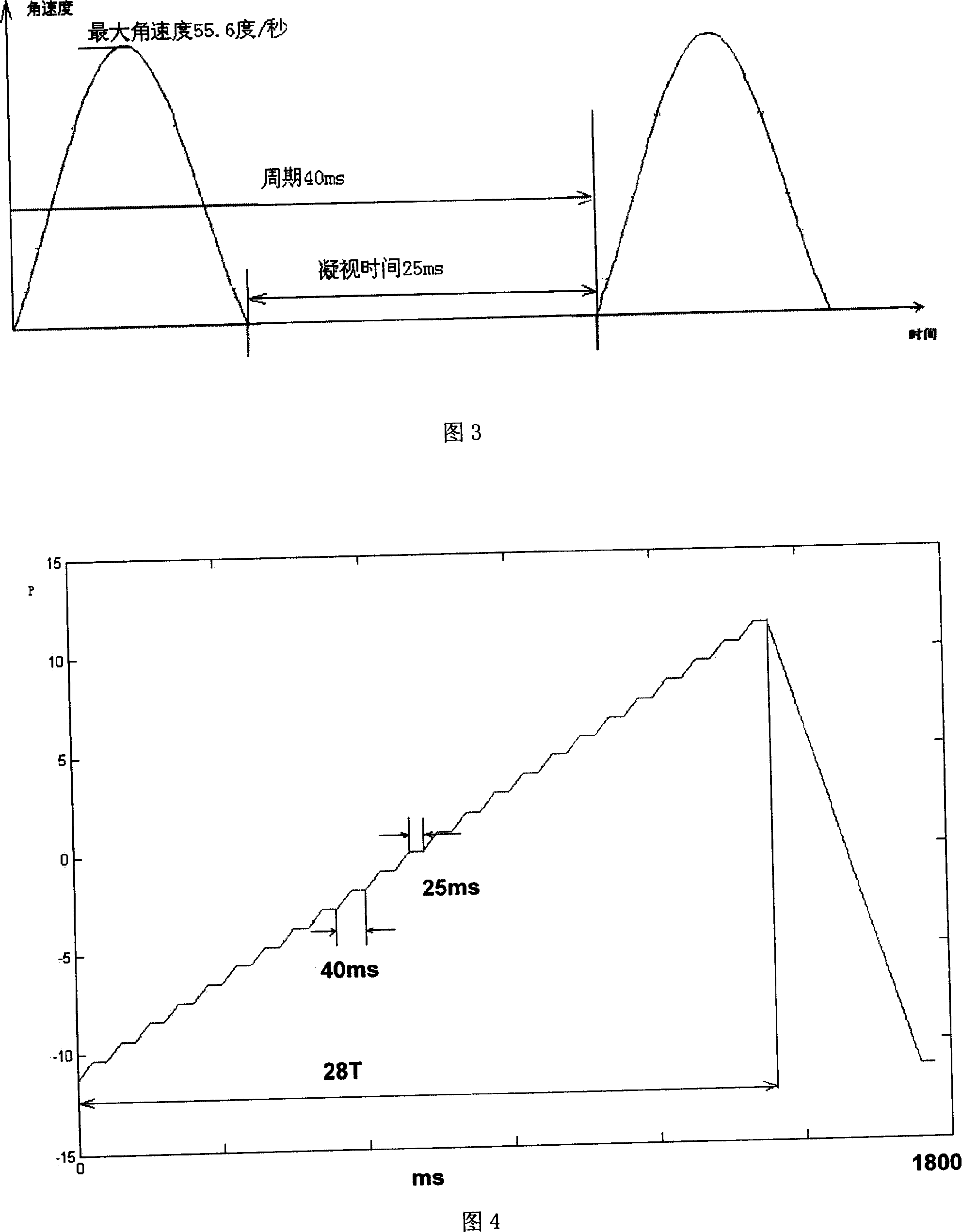

[0027] A high-altitude airborne infrared camera imaging method based on multi-element array stitching of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0028] The specific parameters of the infrared camera are as follows:

[0029] Total field of view: 45°;

[0030] Flight altitude: 12,000-20,000 meters high;

[0031] Number of pixels: 320×256 yuan;

[0032] Instantaneous field of view: 0.1mrad;

[0033] Band: 3 ~ 5um;

[0034] Temperature sensitivity: better than 0.1K;

[0035] Optical system diameter: 100mm.

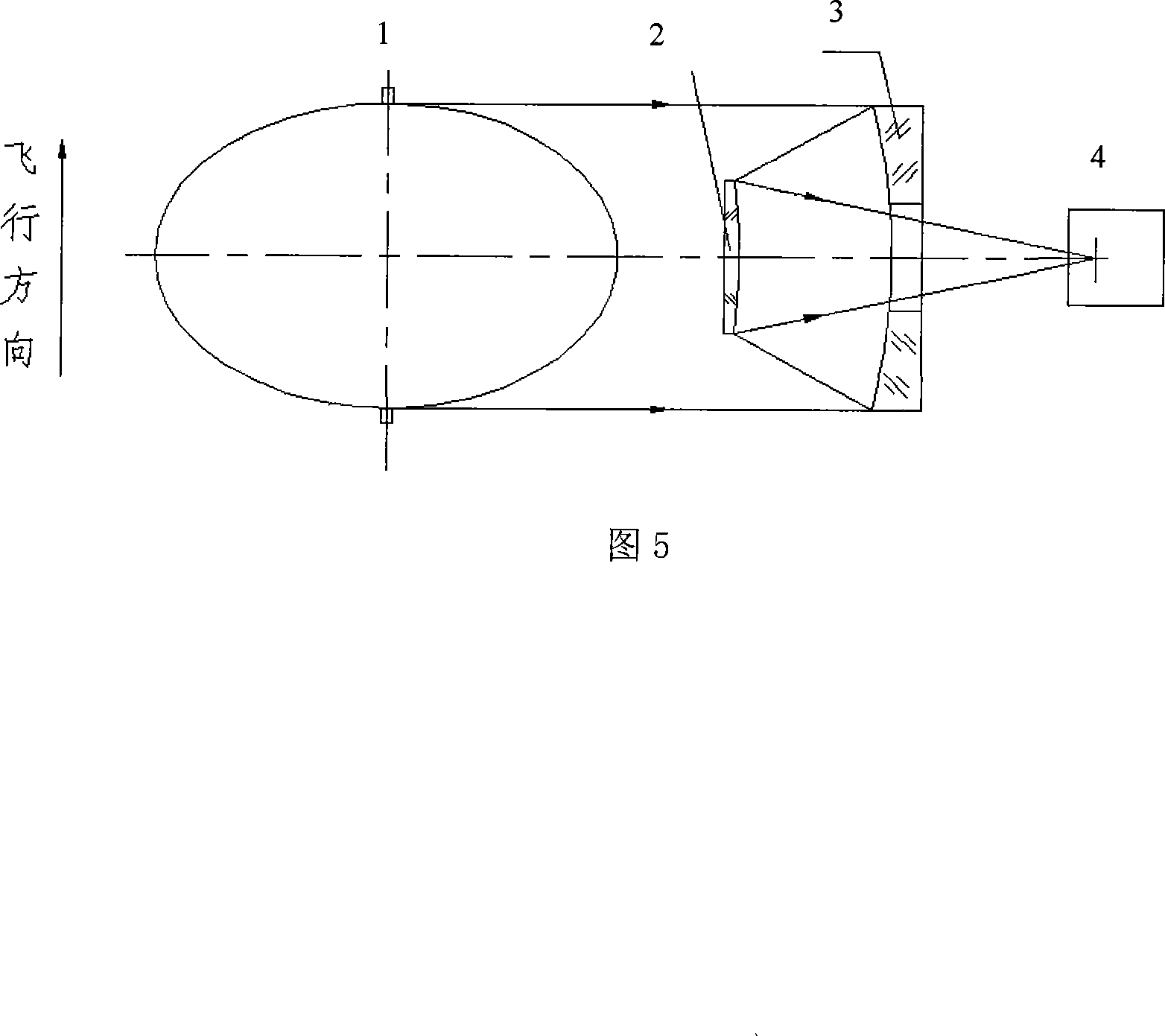

[0036] 1. Oscillating mirror 1 is made of aluminum-magnesium alloy metal mirror, which is driven by a high-precision motor to complete the spatial scanning of the instantaneous field of view of the camera. The scanning angular velocity curve of the pendulum mirror is shown in Figure 3, and the position curve of the pendulum mirror is shown in Figure 4. The drive motor of the swing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com