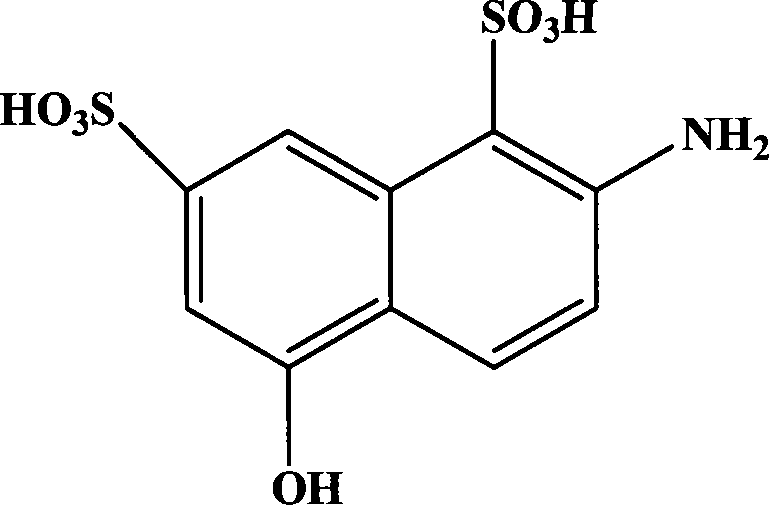

Method for preparing 2-amino-5-naphthol-1,7-disulphonic acid

A technology of disulfonic acid and naphthalenesulfonic acid, which is applied in the preparation of sulfonic acid and organic chemistry, and can solve the problems of equipment corrosion, high consumption, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described below:

[0013] Preparation of 10% alkaline solution of J acid: 1340 kg of water, heated to 45°C, stirred, added 144 kg of J acid, after 30 minutes, added 86-87 kg of 30% sodium hydroxide solution, adjusted pH 6.5- 8. Make it all dissolve, and the dark solution is 10% alkaline solution of J acid.

[0014] Add 150 kilograms of manganese dioxide (75%) in the alkaline solution of 10% J acid that has been configured, stir and add 315 kilograms of sodium metabisulfite with the speed of 105 kilograms / hour after being heated to 45-50 ℃, and in After the addition was complete, the reaction was continued for 30 minutes, and then the reaction was stopped, filtered, and the filtrate was retained.

[0015] 560 kg of 30% hydrochloric acid was slowly added to the above filtrate, and the pH of the solution was 1-2 at this time. Then heat it to 60°C, blow in air to drive away the sulfur dioxide, after 3-4 hours, cool the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com