Adjusting method for oil field injection and extraction system in ultra-high water-containing period

A technology of ultra-high water cut period and adjustment method, which is applied in the field of oil field injection-production system adjustment, and can solve problems such as high water injection pressure, imperfect injection-production well pattern, and water injection capacity that cannot meet the liquid production rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

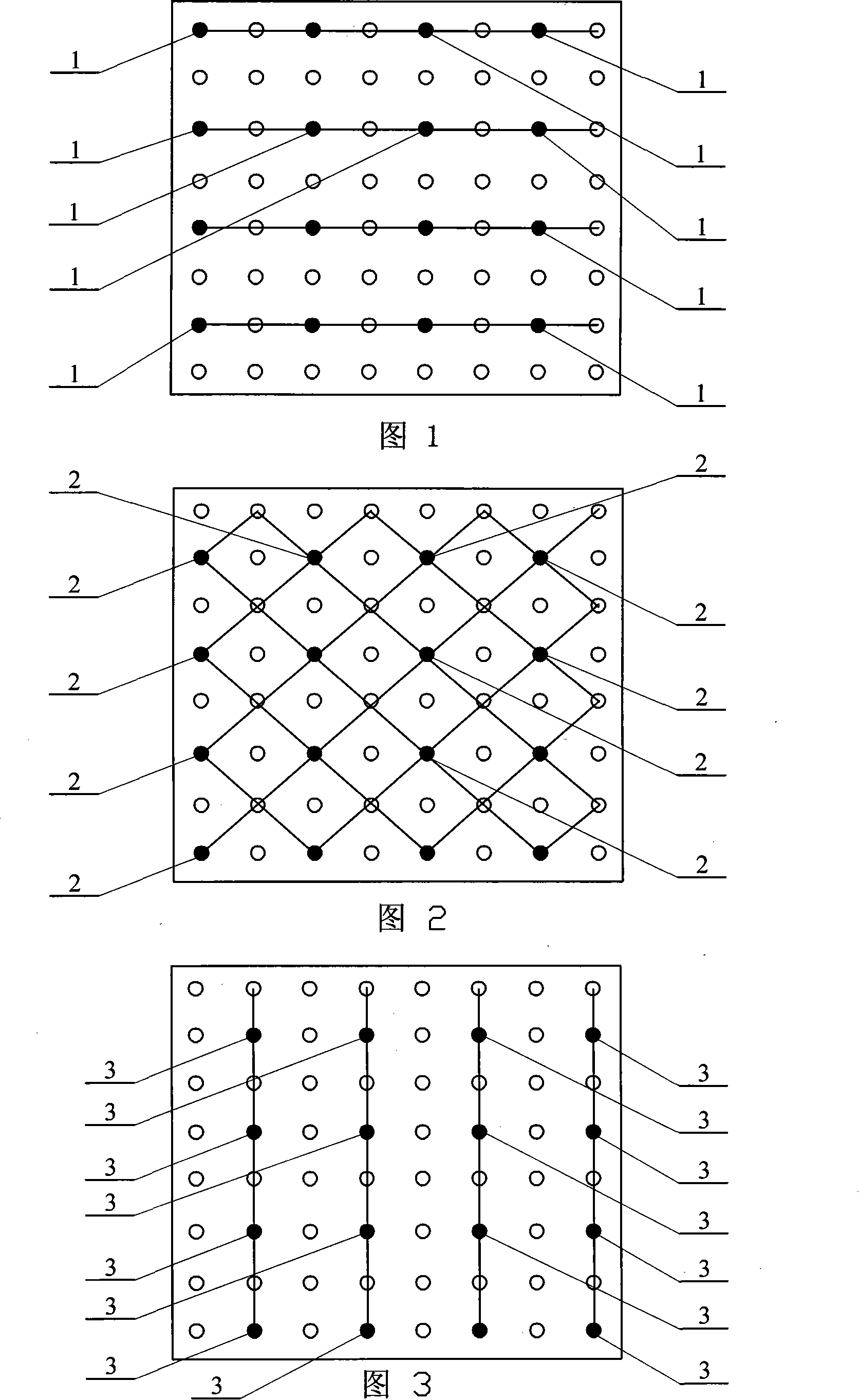

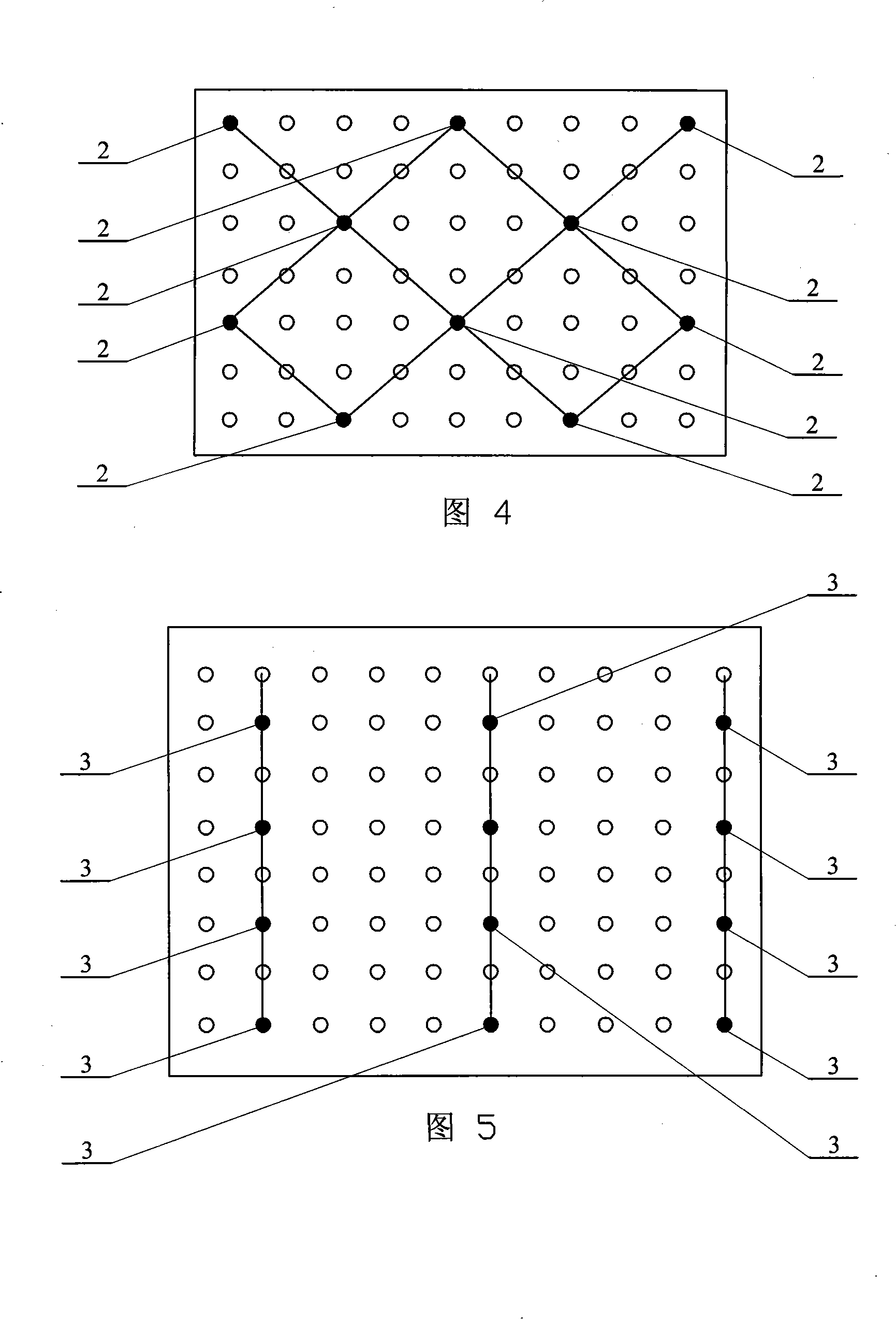

[0005] Specific implementation mode 1: (see Fig. 1 to Fig. 5) the adjustment method of the oilfield injection-production system in the extra-high water-cut period of this embodiment is realized according to the following steps: 1. Firstly, the injection-production system is optimized and adjusted, and the interval between injection and production is adopted. Injection-production mode in which the side wells of the side wells form a horizontal linear water injection well pattern, or the injection-production mode in which the corner wells are transferred to form a five-point area well pattern, or the injection-production method in which the side wells of the injection-production well row form a vertical linear water injection well pattern, or interval The injection-production method in which corner wells are transferred to form massive water injection units, or the side wells of interval transfer-injection and production wells form two rows of water injection wells sandwiched by t...

specific Embodiment approach 2

[0006] Specific embodiment two: (referring to Fig. 1) this embodiment adopts the injection-production mode that the side wells between the injection and the production rows form a horizontal linear water injection well pattern, and the well spacing (between any two adjacent water injection wells and oil production wells) ) adjusted to an average distance of 175m. In this embodiment, the degree of water flooding control is as high as 94.4%, among which the proportion of multi-directional connection is 55.8%, the improvement range is 23.4%, the ultimate recovery value can reach up to 44.7%, and the connection relationship with the original well pattern is good.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see Figures 1 to 5) This implementation mode is combined with the third infill adjustment, and the well spacing (the original well spacing is 250m) is adjusted to increase the producing degree of thin poor oil layers and outer layers. The number of effective directions increased by 1.0 on average for a single well of three infill wells, and the sandstone thickness was 5.9m and the effective thickness was 1.8m for the three infill adjustment layers. After the adjustment, the production degree of the thin and poor oil layer and the outer layer of the three-time intensification adjustment layer has been significantly improved, from 59.6% and 42.4% before the adjustment to the current 70.9% and 50.4% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com