Three-dimensional force integrally assembled type six-dimensional force cell sensor

A force sensor, three-dimensional force technology, applied in the field of six-dimensional force sensor, to achieve the effect of convenient adjustment and installation, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

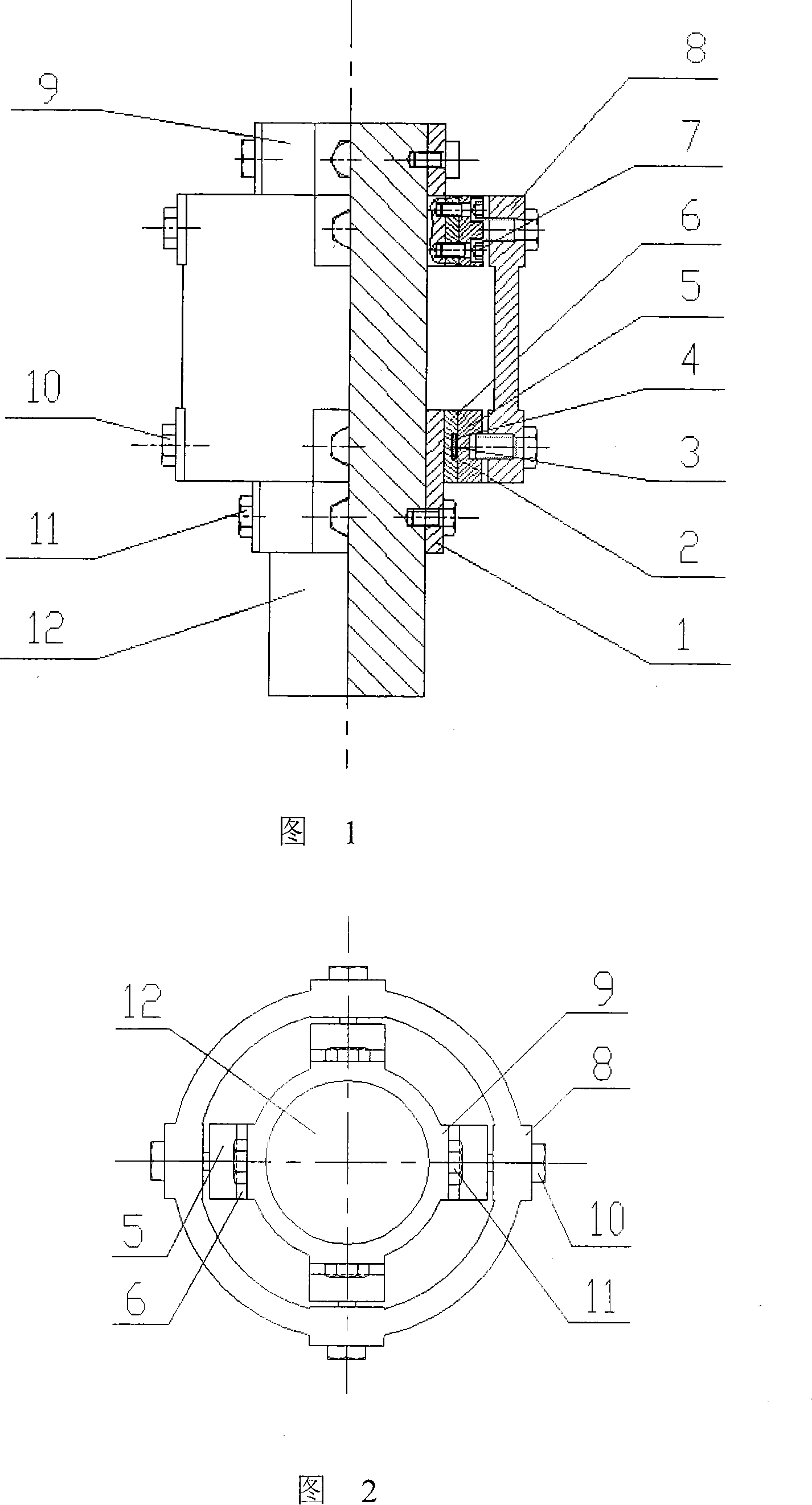

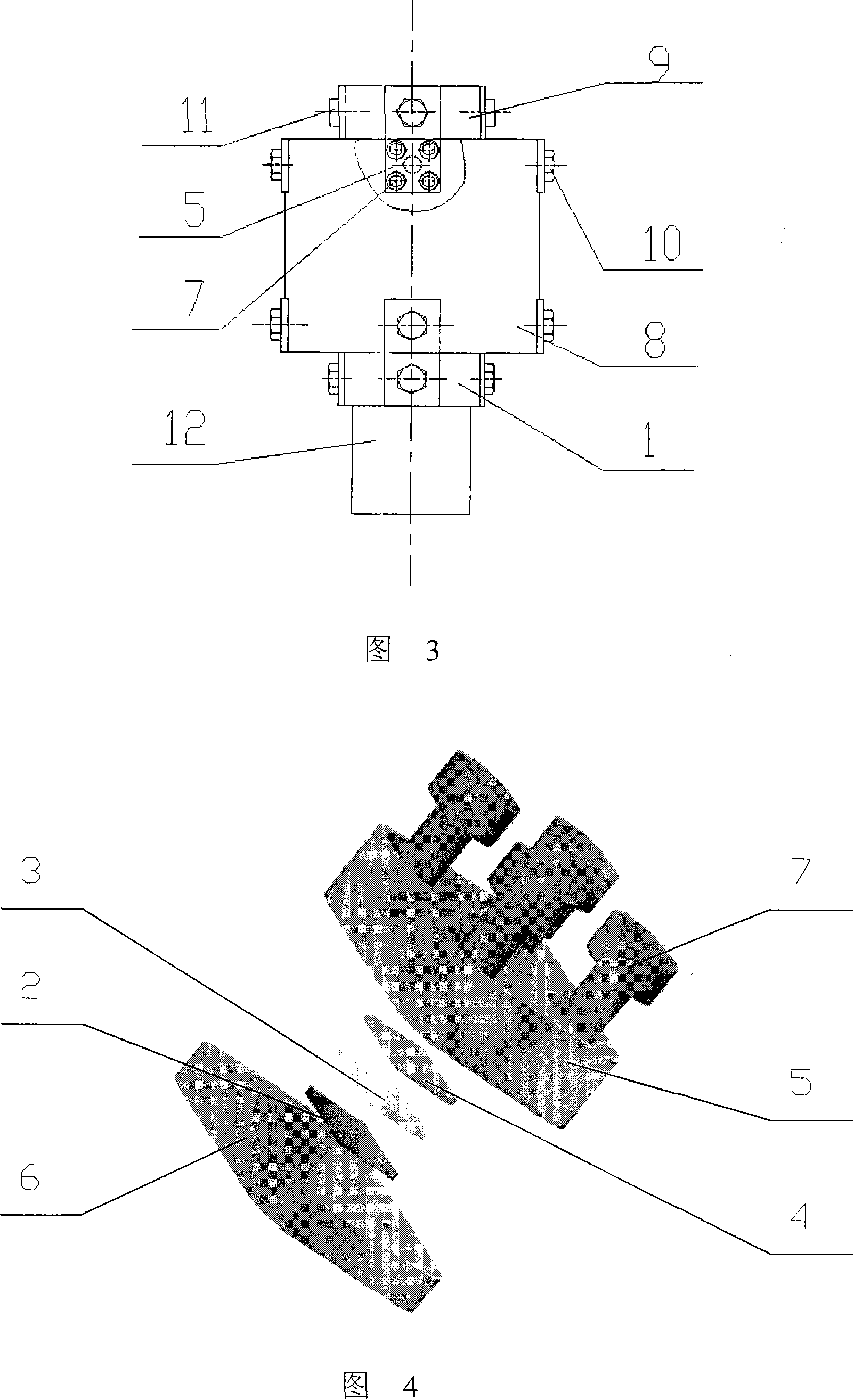

[0014] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The three-dimensional force integral assembly type six-dimensional force sensor designed by the present invention adopts two groups of three-dimensional force quartz wafer groups arranged up and down to form a six-dimensional force measuring mechanism. Fig. 1 is a three-dimensional integral assembly The front view of the six-dimensional force sensor mainly includes eight piezoelectric three-dimensional force quartz chip groups, wherein each three-dimensional force quartz chip group can measure three mutually perpendicular forces, including a piezoelectric Quartz wafer and two piezoelectric quartz wafers capable of measuring shear, two inner sleeves connected to the manipulator arm, and one outer sleeve connected to each three-dimensional force quartz wafer group. The upper inner sleeve 9 and the lower inner sleeve 1 are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com