Method of controlling a hydrostatic drive

A drive and hydrostatic technology, applied in the direction of brakes, brake components, control devices, etc., to achieve the effect of torque increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

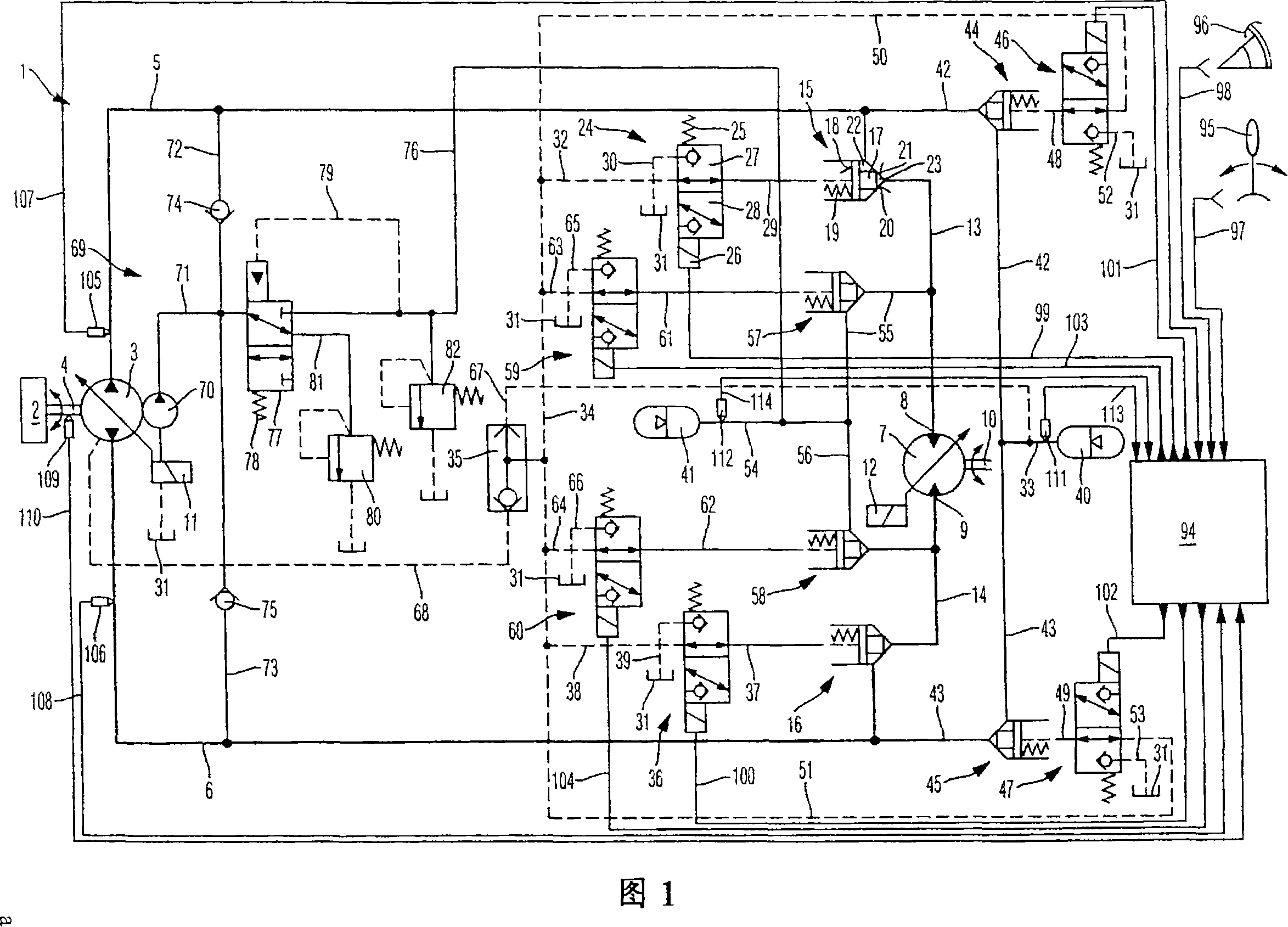

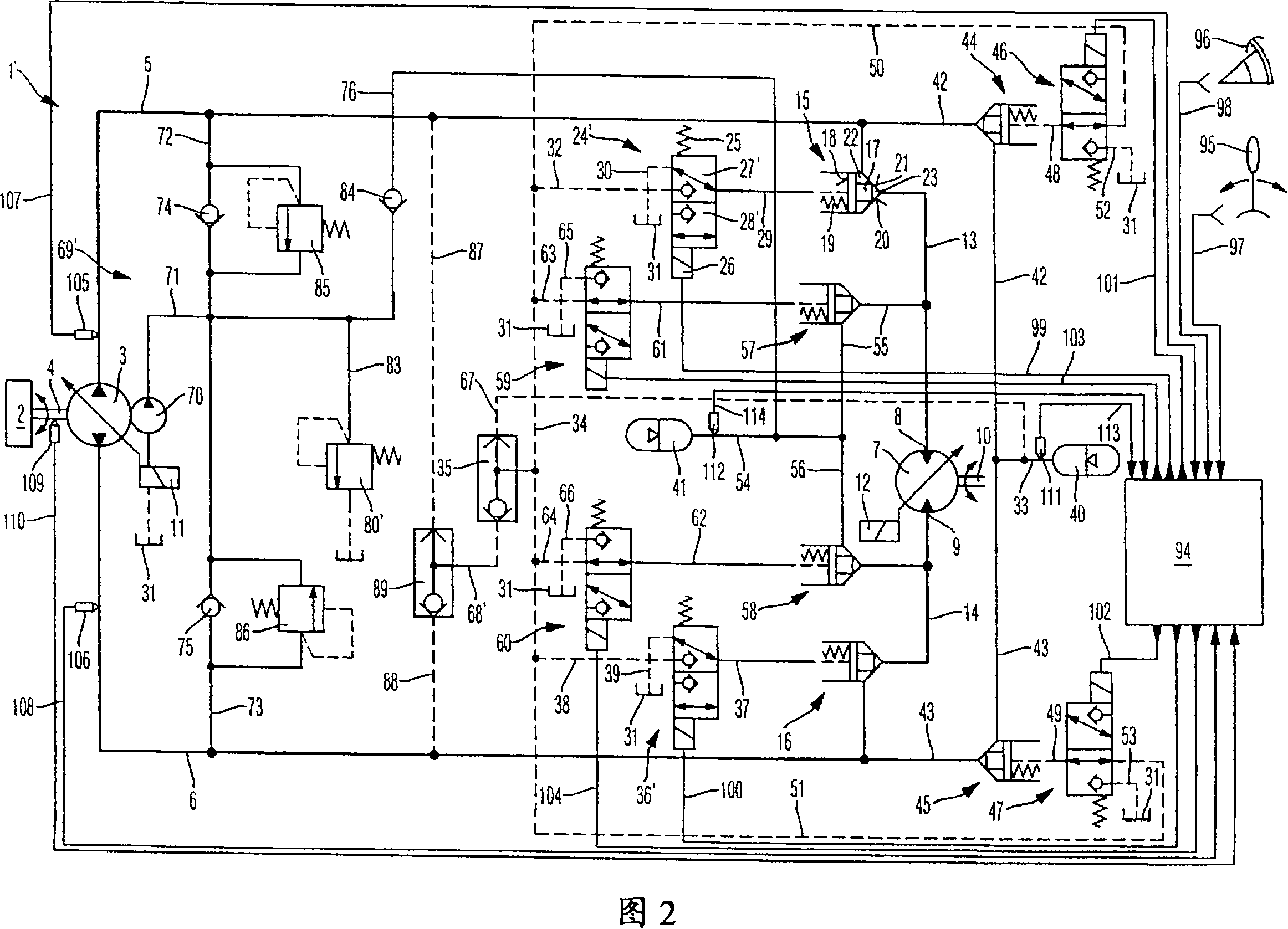

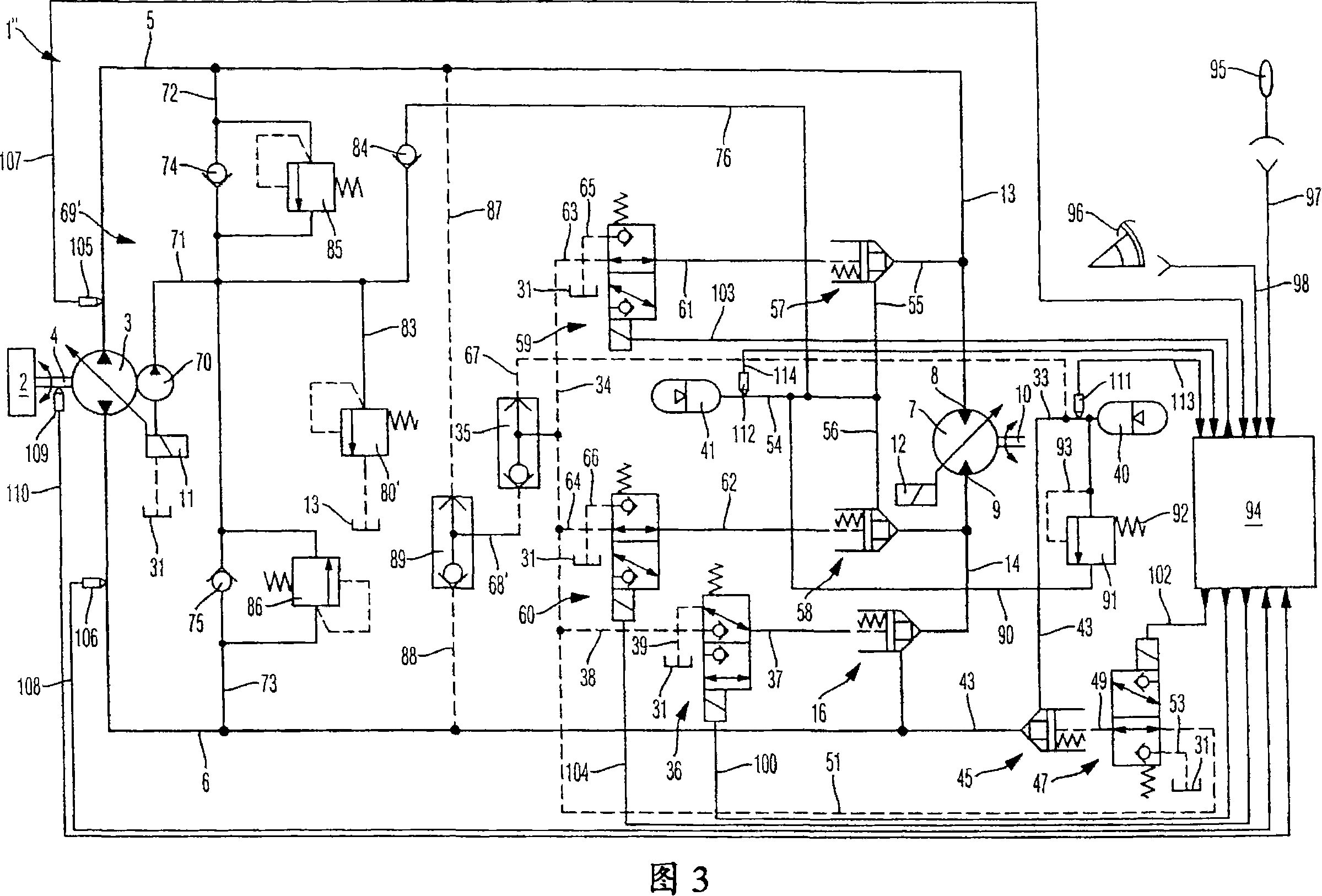

[0028] FIG. 1 shows a schematic view of a hydrostatic drive 1 according to the invention. Said hydrostatic drive 1 according to the invention may for example be a traction type drive in a utility vehicle. However, the invention is not limited to traction drives. Conversely, all drives with hydrostatic transmission can be manufactured with the design according to the invention.

[0029] The hydrostatic drive 1 comprises a drive engine 2 . The drive engine 2 drives a hydraulic pump 3 through a drive shaft 4 . The hydraulic pump 3 is an adjustable hydrostatic piston mechanism that can be designed for bi-directional transmission. The hydraulic pump 3 can be delivered into the first working line 5 or the second working line 6 according to the set delivery direction. A hydraulic engine 7 is connectable to the first working line 5 and the second working line 6 . The hydraulic engine 7 has a first working line connection 8 and a second working line connection 9 . The first worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com