Method of dispensing in reaction vessel and reaction vessel processing apparatus

A reaction vessel and reaction technology, applied in the direction of chemical instruments and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of good determination, non-separated liquid, evaporation of reaction liquid, etc. problem, to achieve the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

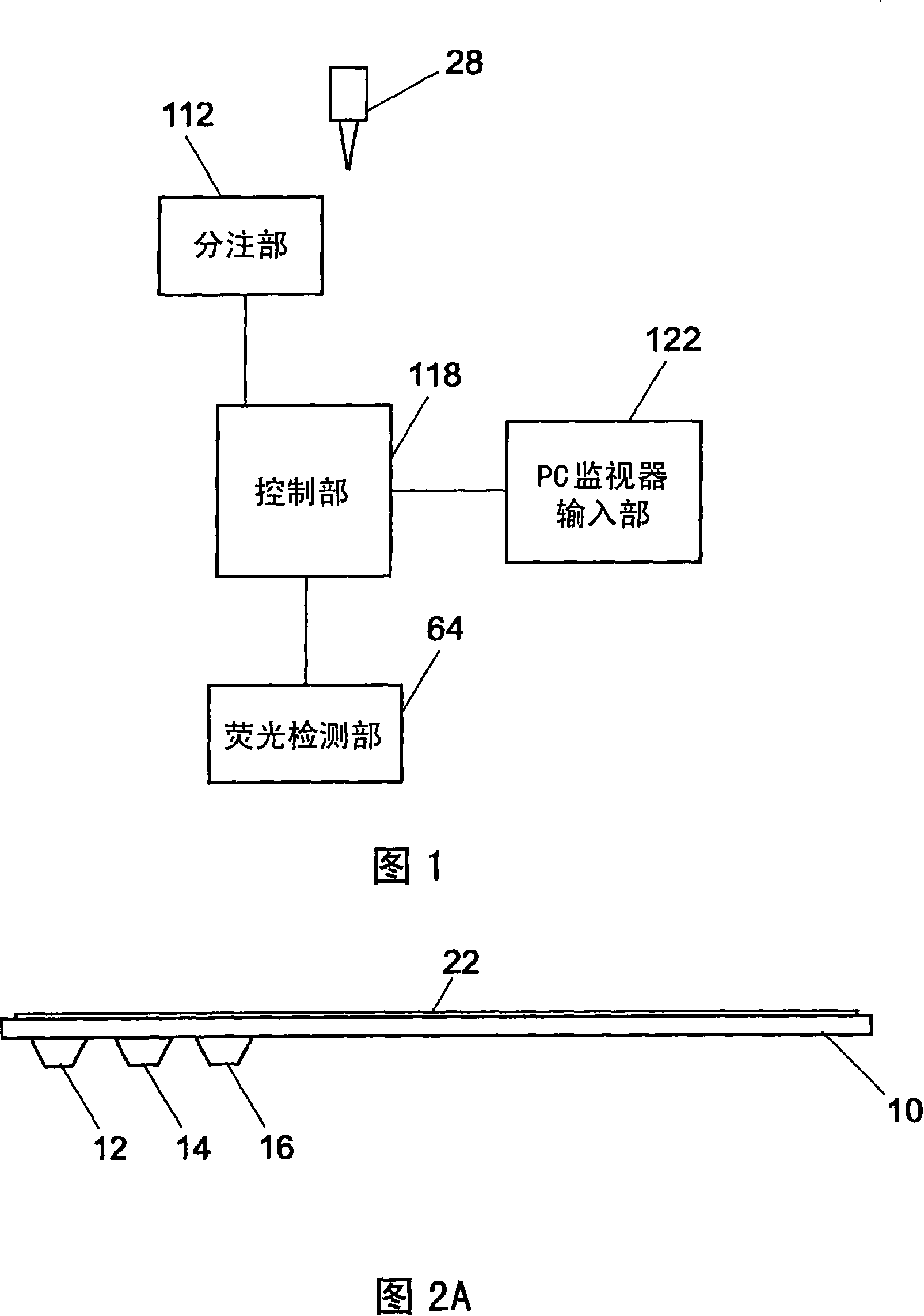

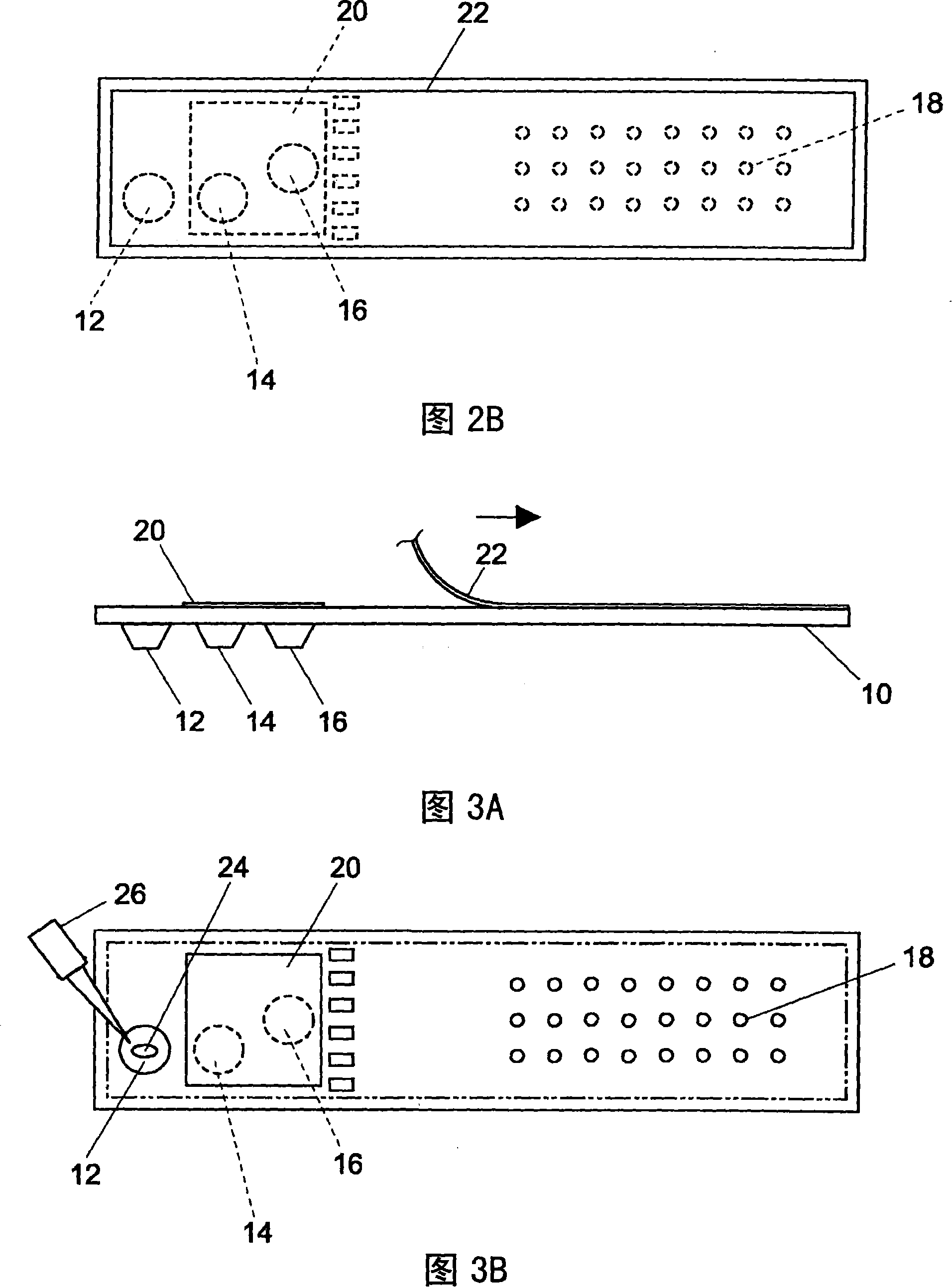

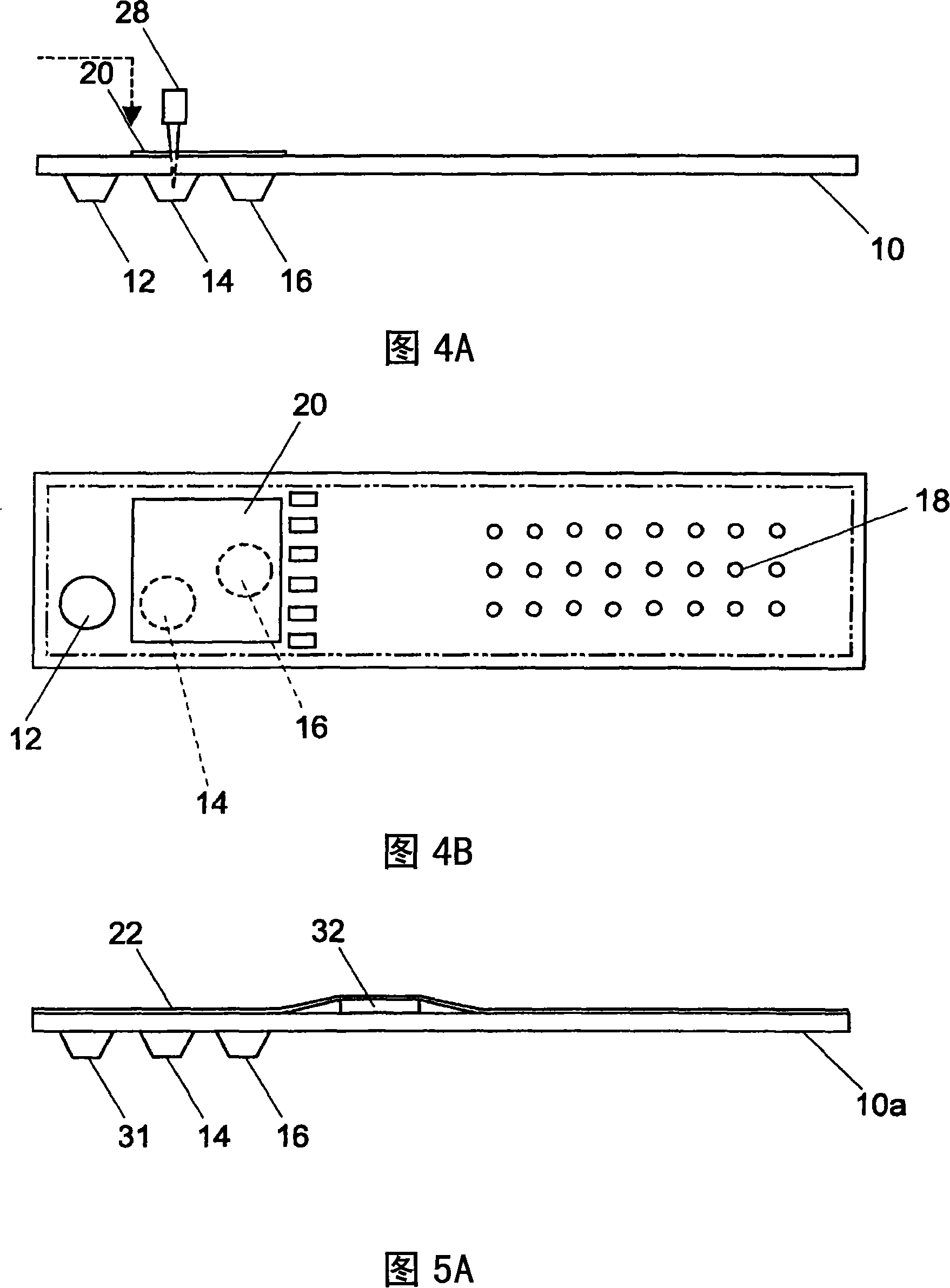

[0055] 2A and 2B show the first example of the reaction vessel used in the reaction vessel processing apparatus of the present invention. Fig. 2A is a front view, and Fig. 2B is a top view.

[0056] On the same side of the flat substrate 10, the reagent storage portion 14 and the non-volatile liquid storage portion 16 are formed as recesses. In the following, mineral oil is used as a non-volatile liquid. The non-volatile liquid container is called a mineral oil container. Further, a reaction part 18 is formed on the same side of the substrate 10. The reagent storage portion 14 and the mineral oil storage portion 16 are sealed by a thin film 20. When the reagent and mineral oil are sucked in by a nozzle and transferred to other places, the thin film 20 is removed and the nozzle is sucked, or the nozzle can be used to penetrate the thin film 20. Penetrate the film and suck in with a nozzle.

[0057] From the film 20, the surface of the substrate 10 is covered with a peelable sealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com