Anisotropic electrically conductive structure

一种导电结构、各向异性的技术,应用在绝缘载体上的导电层、导电材料、导电材料等方向,达到实现连接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to examples. It should be understood that the present invention is by no means limited to these Examples.

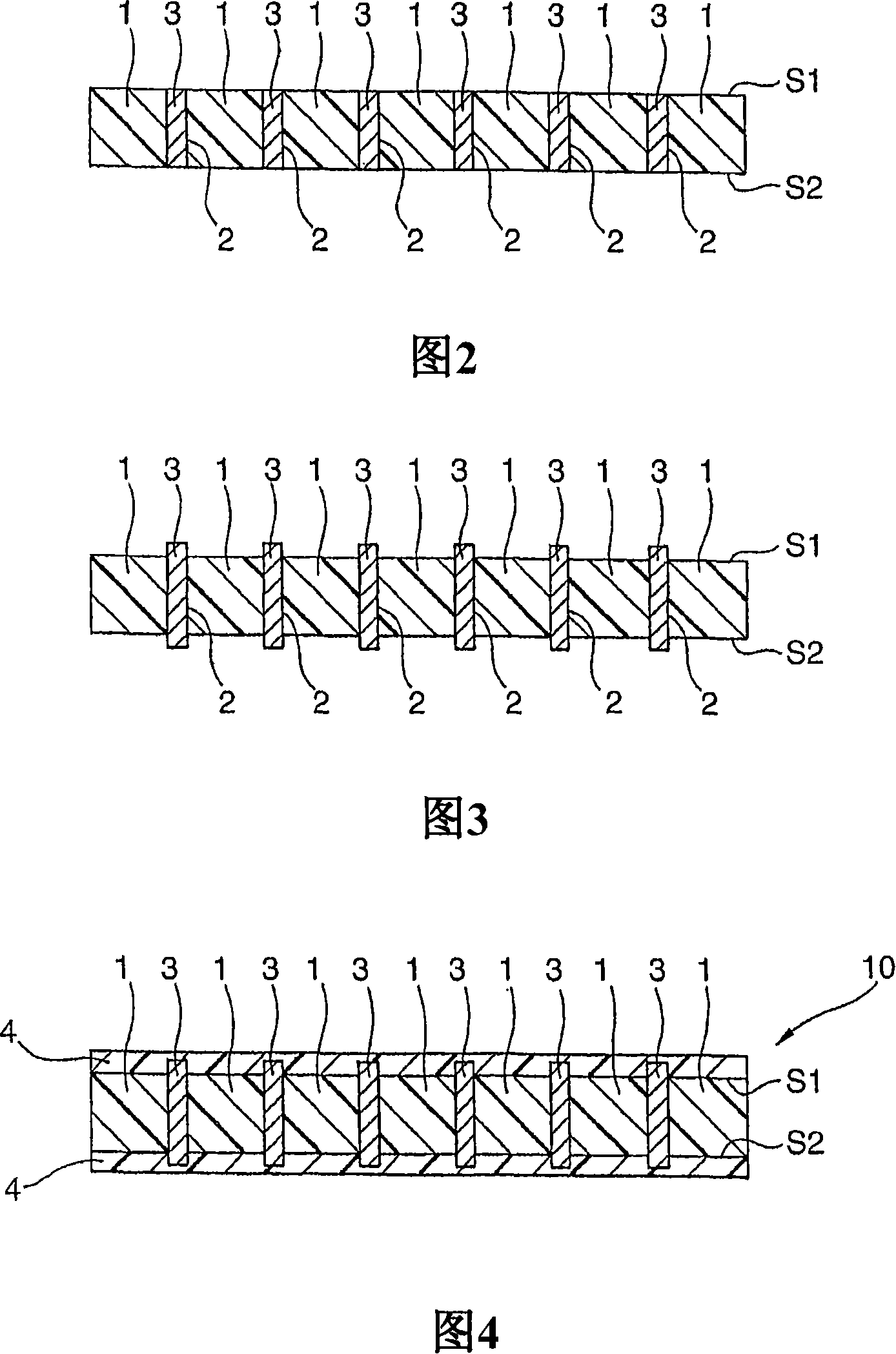

[0016] The anisotropic conductive structure includes: a dielectric substrate having a first surface and a second surface; a thermally cured adhesive layer disposed on at least one or both of the first plane and the second plane; at least from a plurality of channels extending from the first surface of the substrate to the second surface; and a conductive member in the channels; wherein, at a temperature required to thermally cure the heat-curable adhesive layer, The dielectric matrix does not exhibit thermal fluidization.

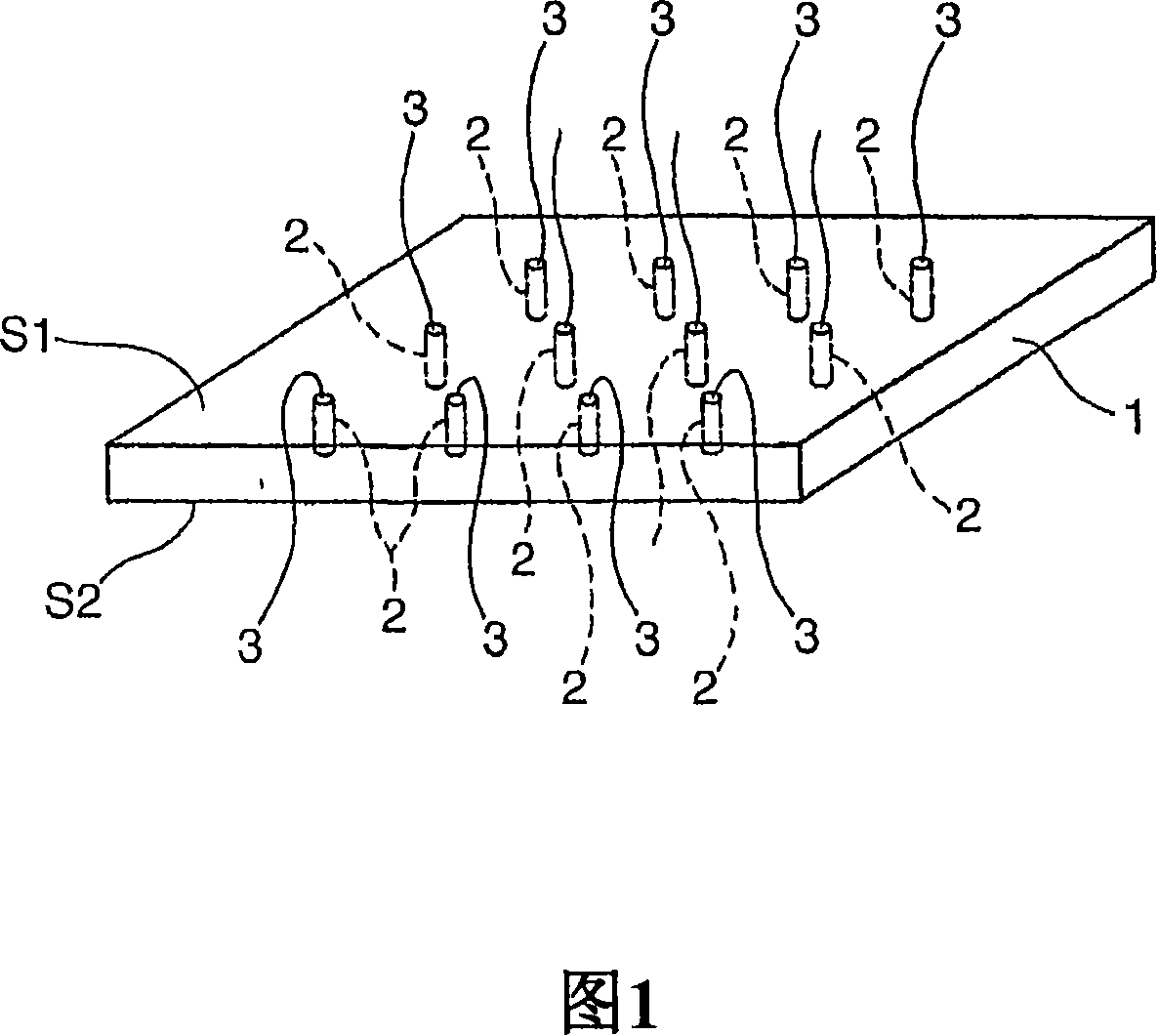

[0017] 1 and 2 are perspective and cross-sectional views, respectively, showing an embodiment of a structure including conductive members in a plurality of channels extending from a first surface to a second surface of a dielectric substrate. As shown, the conductive members 3 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com