Liquid assisting agitating apparatus

An auxiliary stirring and liquid technology, which is used in mixers with rotating stirring devices, reducing greenhouse gases, and mixers, etc., can solve the problems of high power consumption, large volume, and large number of fast mixing tanks and rubber feather tanks. , to reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

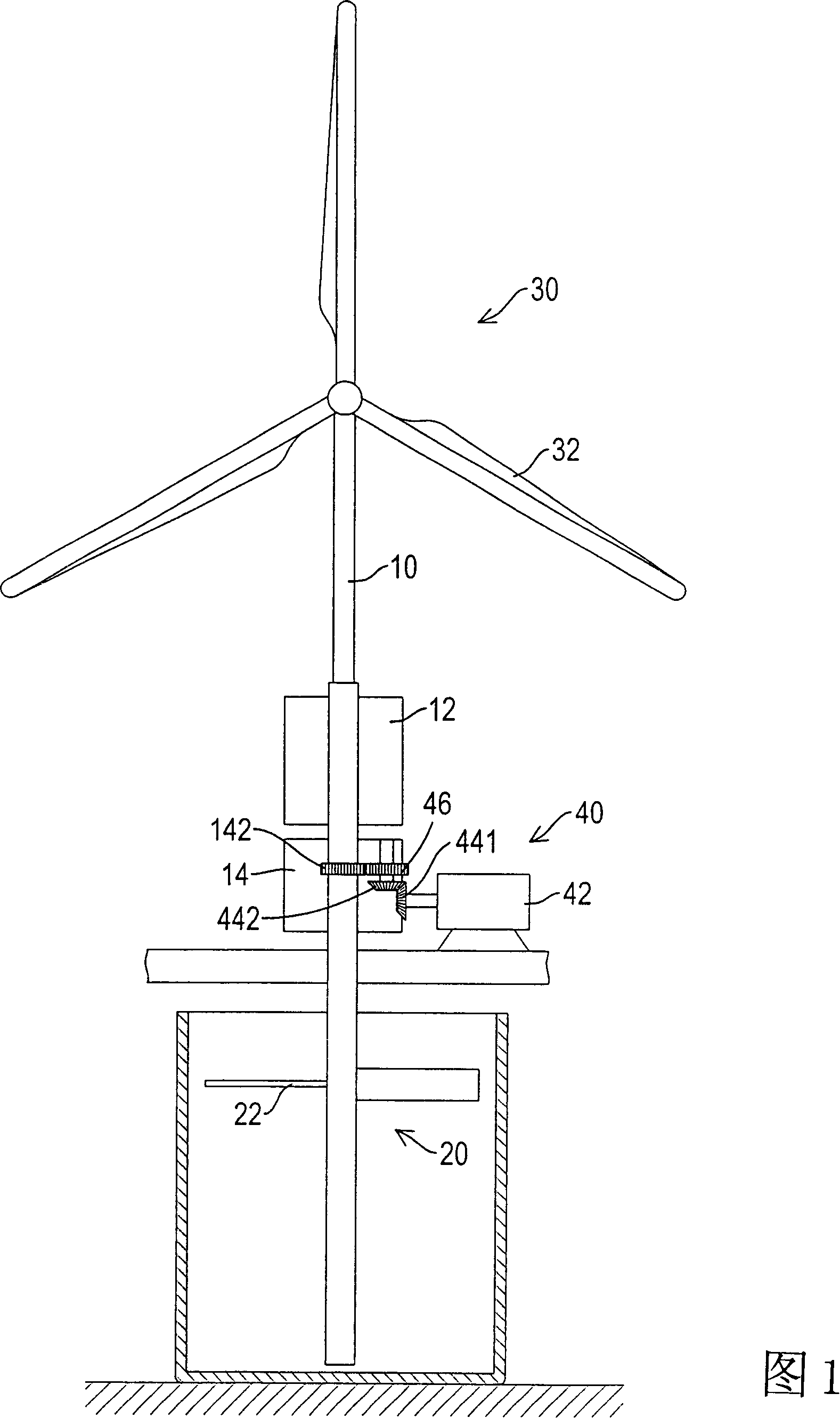

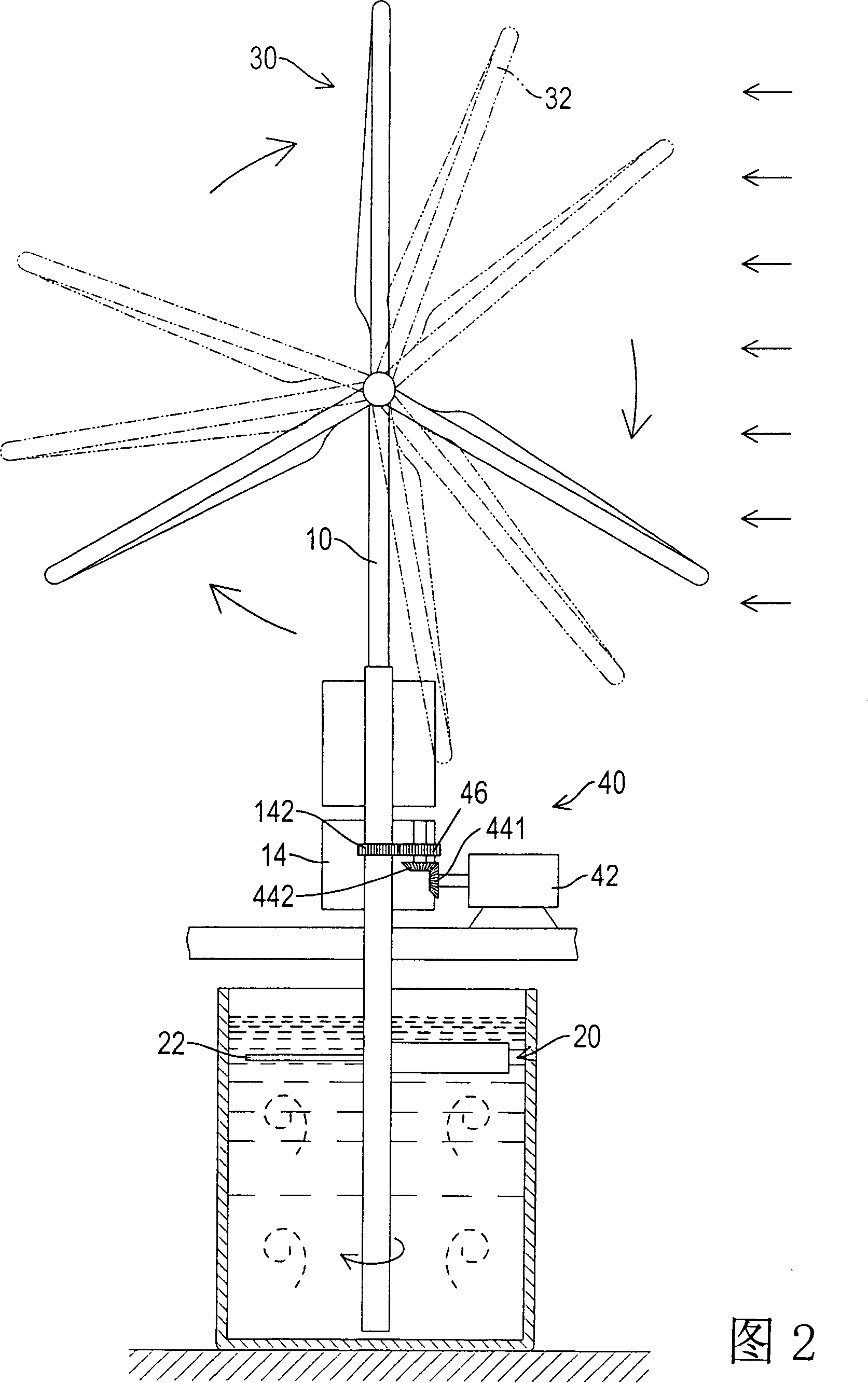

[0039] Please refer to Fig. 1 and shown in Fig. 2, the preferred embodiment of the liquid auxiliary stirring device of the present invention is shown in the figure, and its main structure includes a central shaft 10, a stirring beat blade group 20, a wind drive device 30 With an electric auxiliary drive device 40 .

[0040] The central shaft 10 is vertically set up in the stirring tank like a water purification system, and has a bottom and a top, and its length needs to exceed the height of the stirring tank so that the top protrudes out of the stirring tank. A plurality of axial vanes 12 are arranged in the middle section, and a gear box 14 is installed under the axial vanes 12 , and a gear ring 142 is sleeved on the shaft center of the gear box 14 .

[0041] The stirring blade group 20 is set under the central shaft 10, and it consists of multiple blades 22 arranged on the central shaft 10 according to different inclinations, so when the central shaft 10 rotates, it can dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com