Malfunction detection system and method thereof

A technology for fault detection and line faults, applied in the direction of error detection/correction, measuring electricity, measuring devices, etc., can solve problems such as abnormal switch board key combination functions, increased detection costs, excessive tin, etc., to achieve the best industrial utilization value and increase Difficulty, the effect of reducing the cost of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

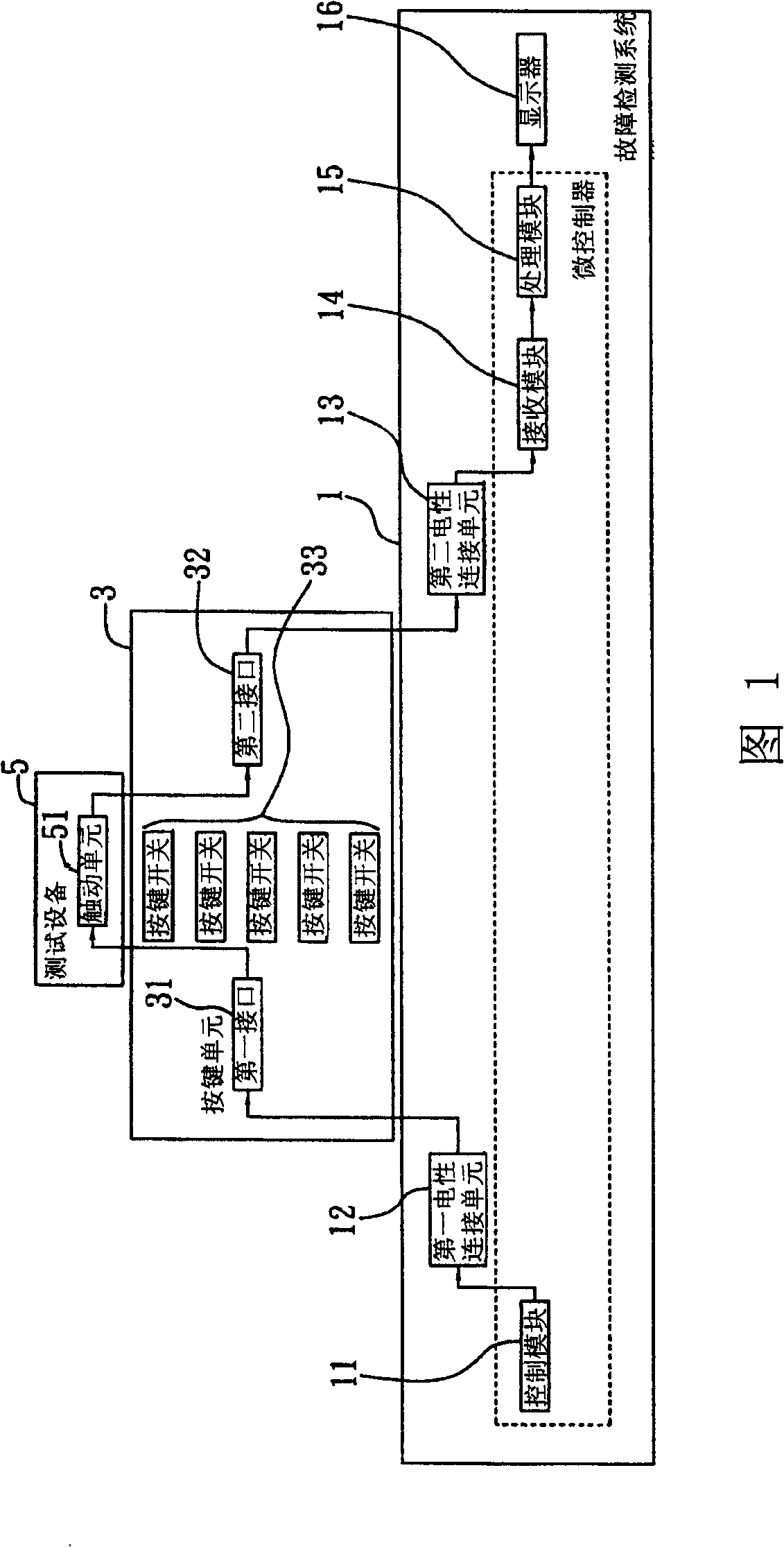

Method used

Image

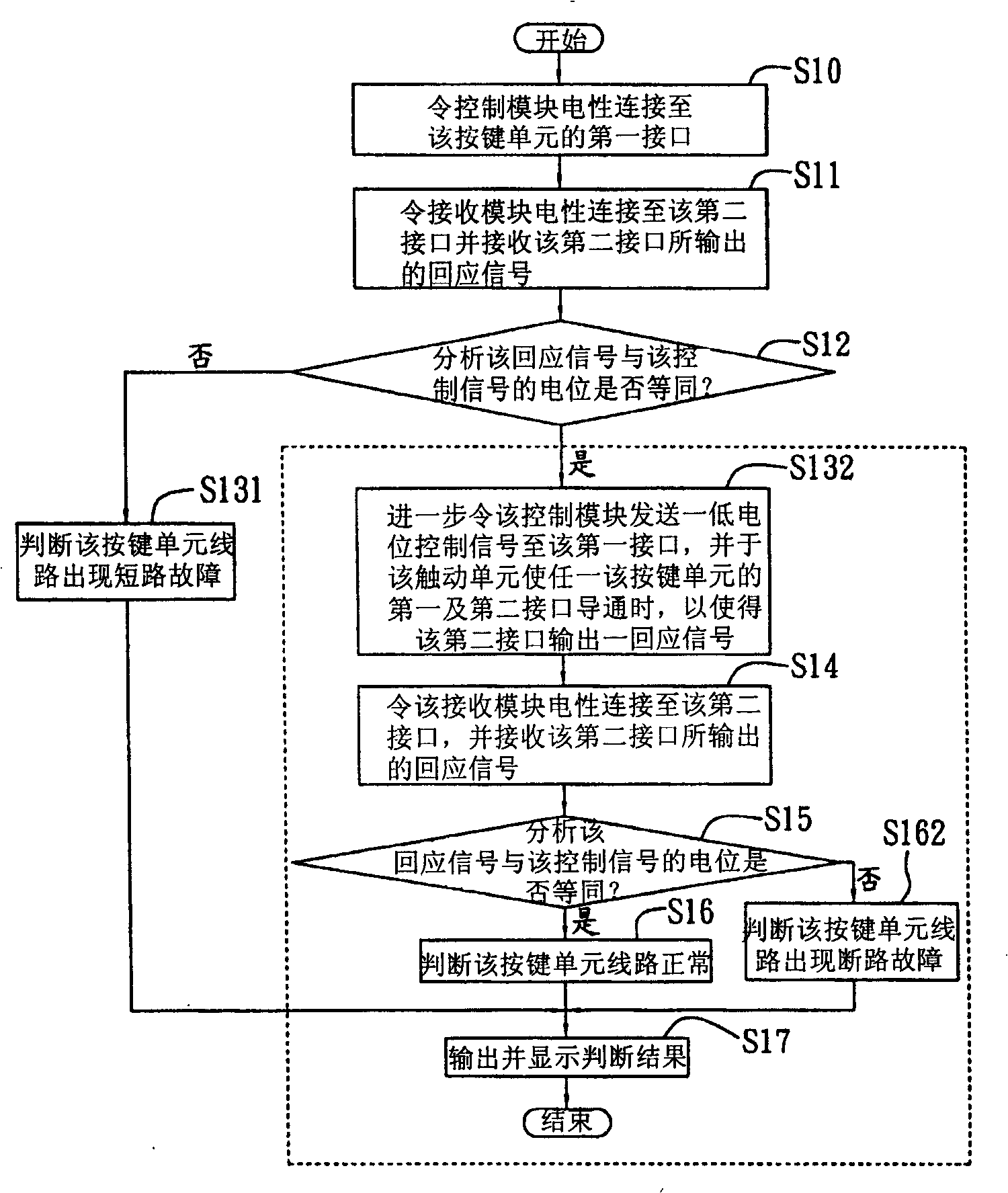

Examples

no. 1 example

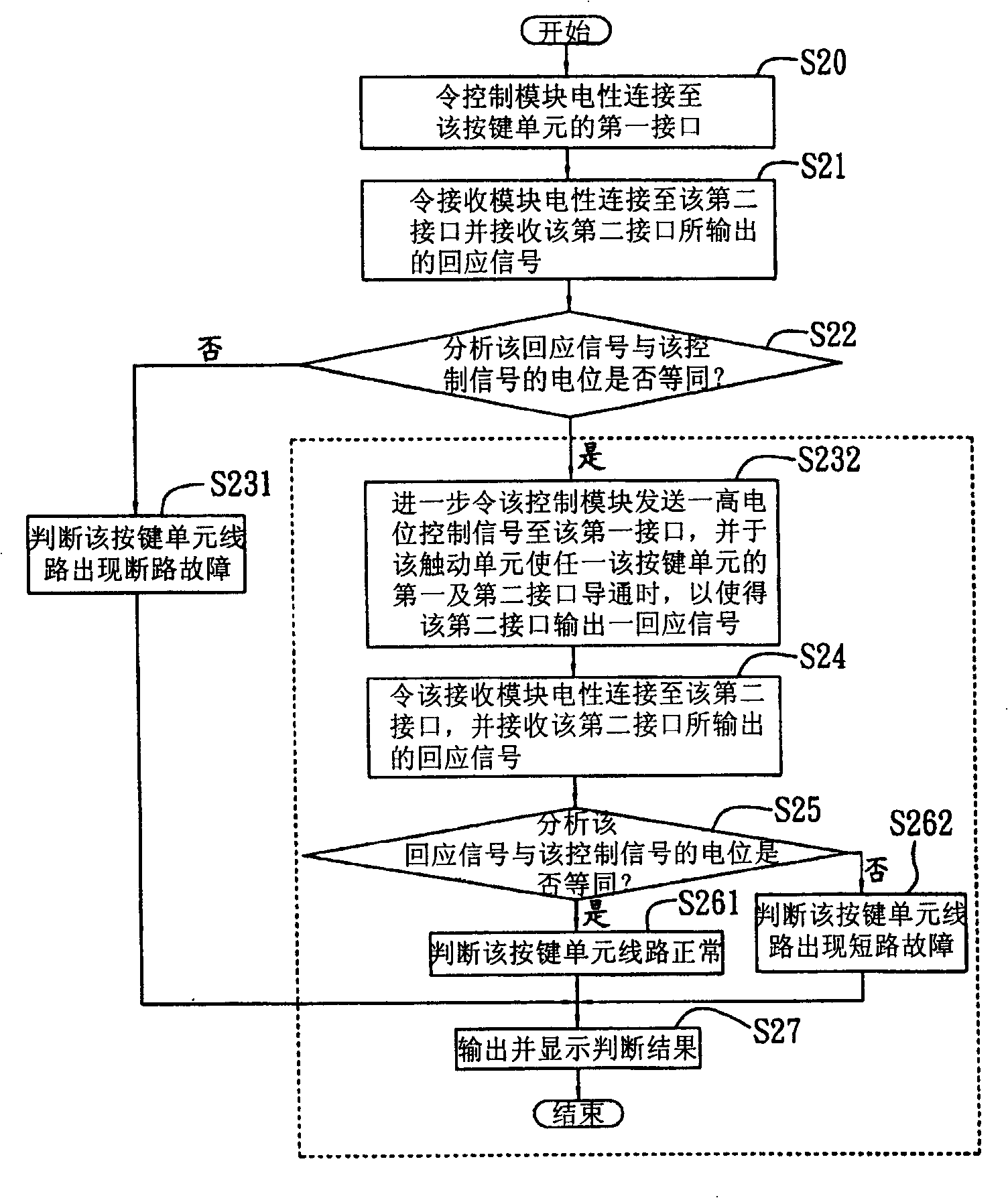

[0062] The difference between this embodiment and the preceding embodiments is that the fault detection method of the present invention is to make the control signal (in step S20) provided by the control module 11 for the first time be a low potential signal, and then according to the high potential signal sent by the control module 11 Signal control signal and the response signal received by the receiving module 14, when analyzing that the response signal is not equal to the control signal (that is, the response signal is a high potential signal at this time), determine the specific key switch 33 circuit of the key unit 3 Open circuit failure occurs (in step S231); when analyzing that the response signal is equal to the control signal (that is, the response signal is also a low potential signal at this moment), the control signal sent by the control module 11 is switched from low potential to The high potential signal is sent to the first interface 31 of the button unit 3 (in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com