Hydrostatic drive and method for braking a hydrostatic drive

A hydrostatic, drive technology used in transmission control, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

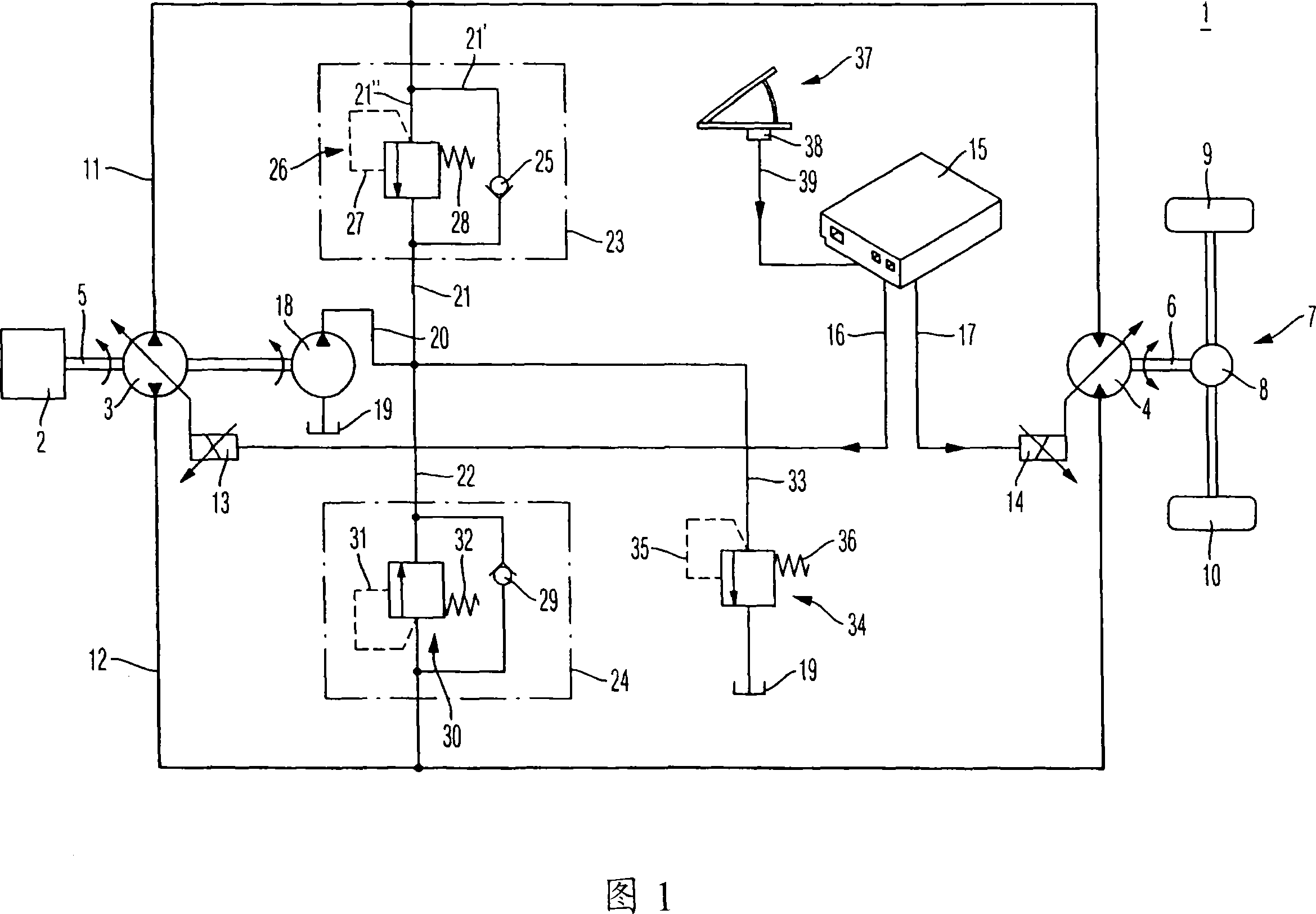

[0018] A hydrostatic drive according to the invention is shown in FIG. 1 . A drive motor 2 is used as the main drive source, usually in the form of an internal combustion engine, preferably a diesel internal combustion engine. The hydrostatic drive 1 according to the invention may for example be a hydrostatic transmission for a hydrostatically driven vehicle such as a forklift or a construction machine, but the invention is not limited to such drives.

[0019] The drive motor 2 drives the variable displacement hydraulic pump 3 . The variable displacement hydraulic pump 3 is designed for transmission in both directions and is preferably an axial piston machine of inclined shaft or swash plate design. The hydraulic motor 4 is connected to the hydraulic pump 3 in a closed circuit. The hydraulic motor 4 is likewise designed to work in both flow directions. The absorption capacity of the hydraulic motor 4 is also adjustable.

[0020] In order to drive the hydraulic pump 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com