Low temperature storing grain method and system

A low-temperature, grain-stacking technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problems of inability to meet the technical requirements of low-temperature grain storage and poor cooling effect, and achieve low cost and long life The effect of long life and small installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

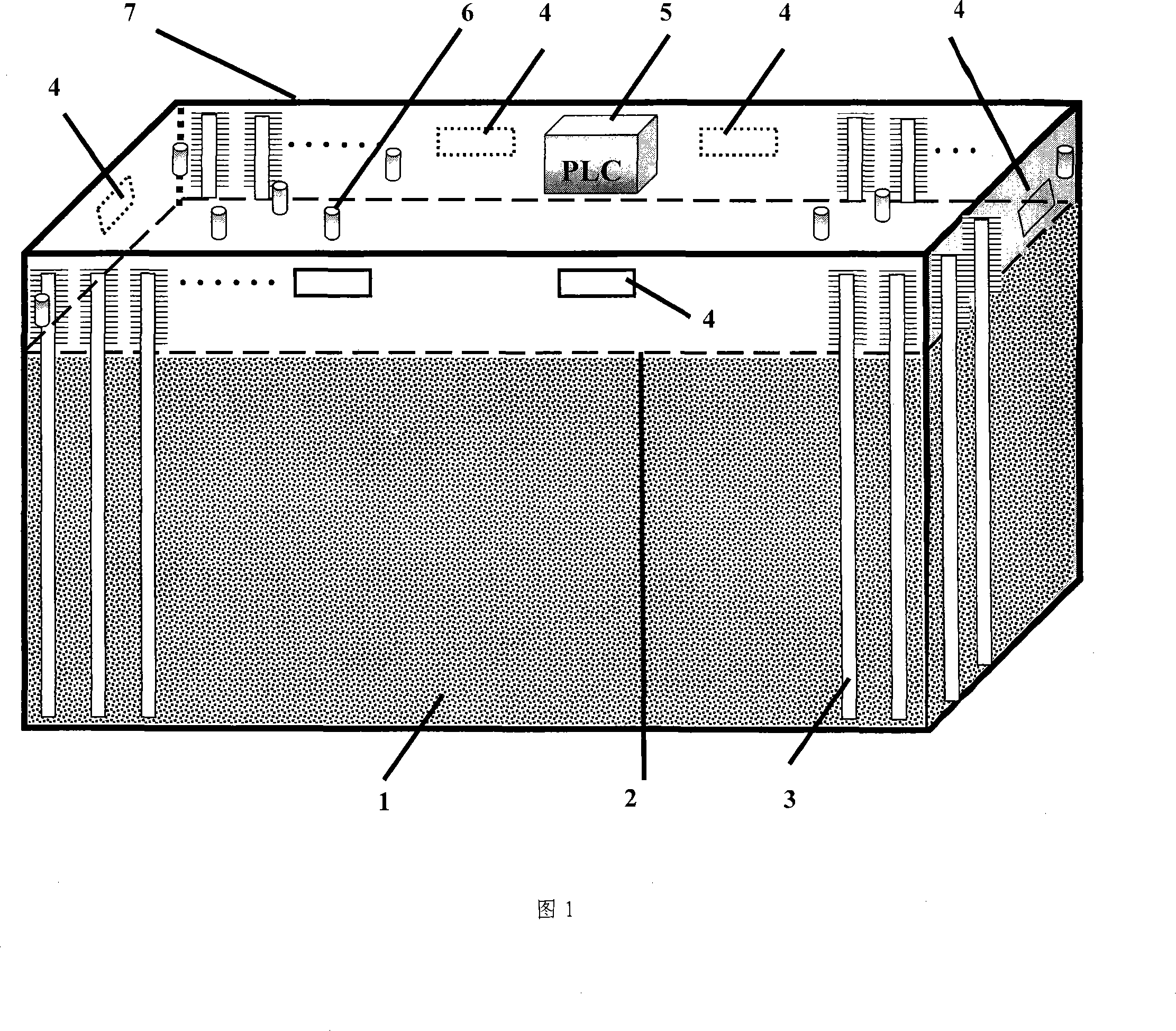

[0015] As shown in Figure 1, the system consists of a single-cooling split wall-mounted inverter air conditioner 4, a low-temperature gravity heat pipe 3 suitable for the heat transfer characteristics of indica and stalk rice, a PLC control system 5, and a temperature sensor 6. The composition and working principle of this system will be further described below in conjunction with Fig. 1, Fig. 2 and Fig. 3 .

[0016] 1. Circulating cold air system

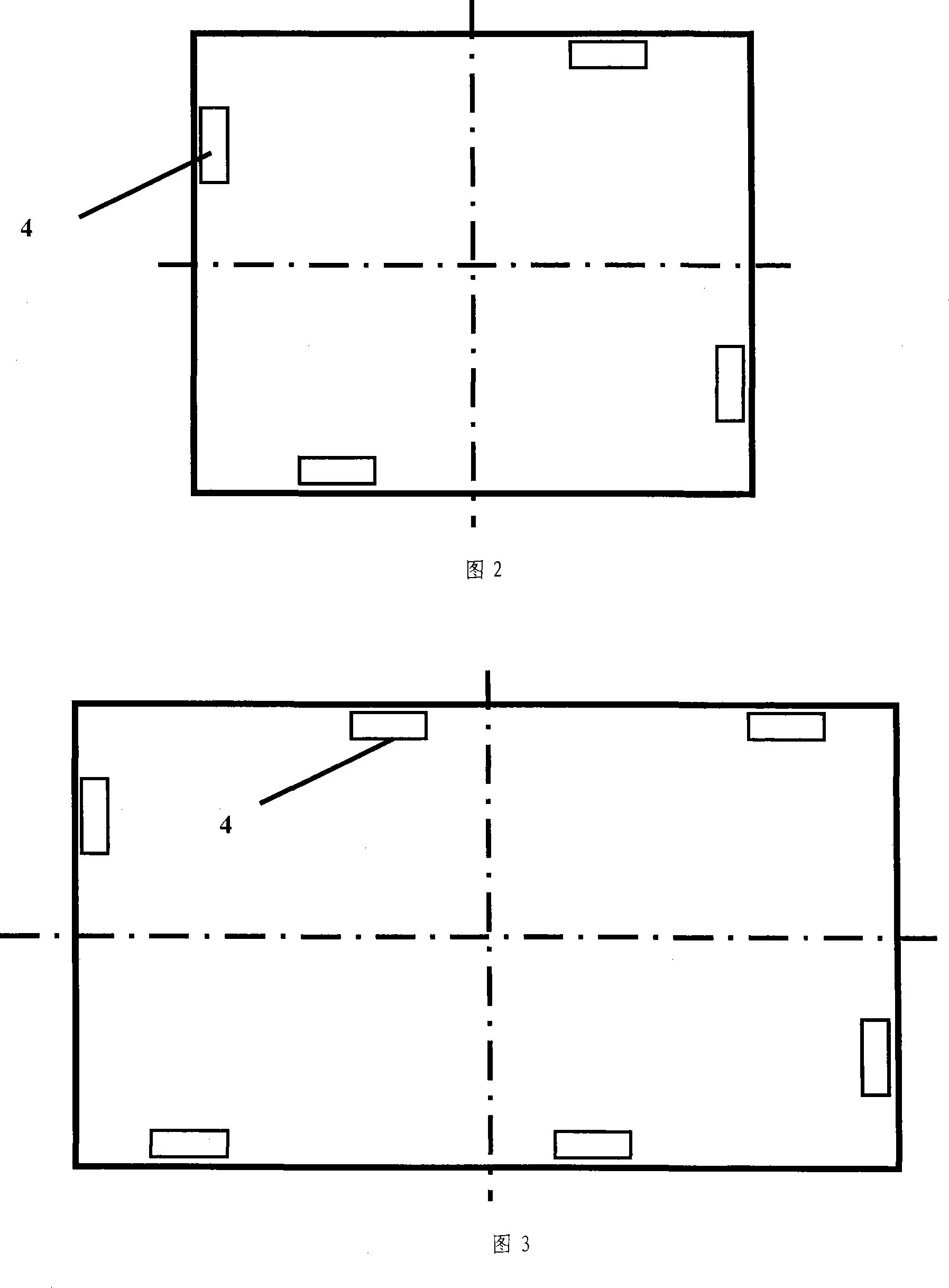

[0017] Cooling-only split wall-mounted inverter air conditioner 4 provides cooling air. Four or six single-cooling split wall-mounted inverter air conditioners are evenly and staggeredly installed on the upper part of the top surface 2 of the grain pile inside the room. See Figure 2 and Figure 3 for specific installation locations. The cold wind blown out forms a clockwise or counterclockwise circulation, thereby making the temperature of the cooling space more uniform. As shown in Figure 2, if the room is square, you need to inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com