Cam axle underneath type valve mechanism of motorcycle engine

A valve train, camshaft technology, applied in engine components, machines/engines, valve drives, etc., can solve problems such as low engine power, torque and even efficiency, inability to meet design requirements, and inability to achieve timing valve distribution. Eliminate over-restraint, reduce valve noise, high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

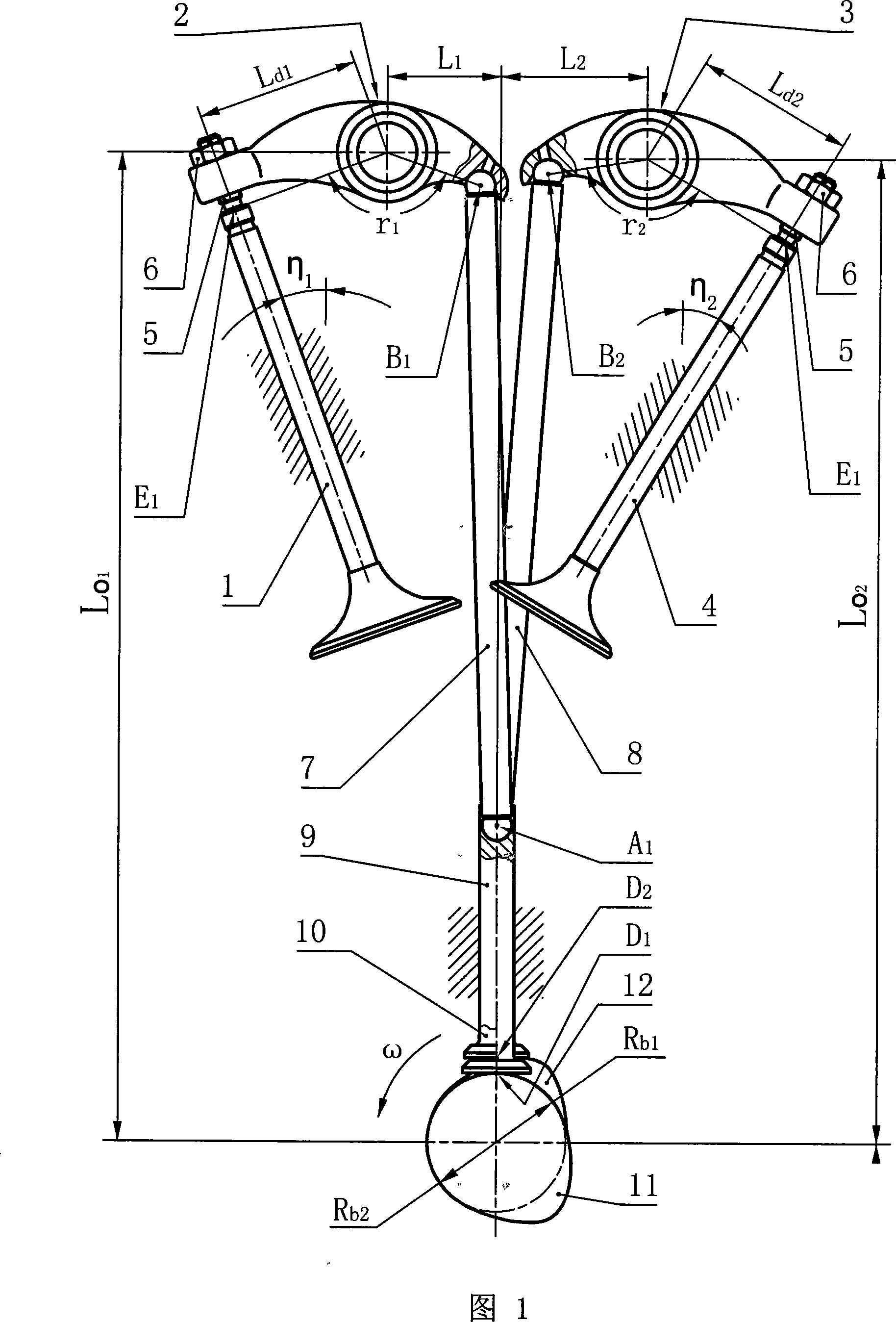

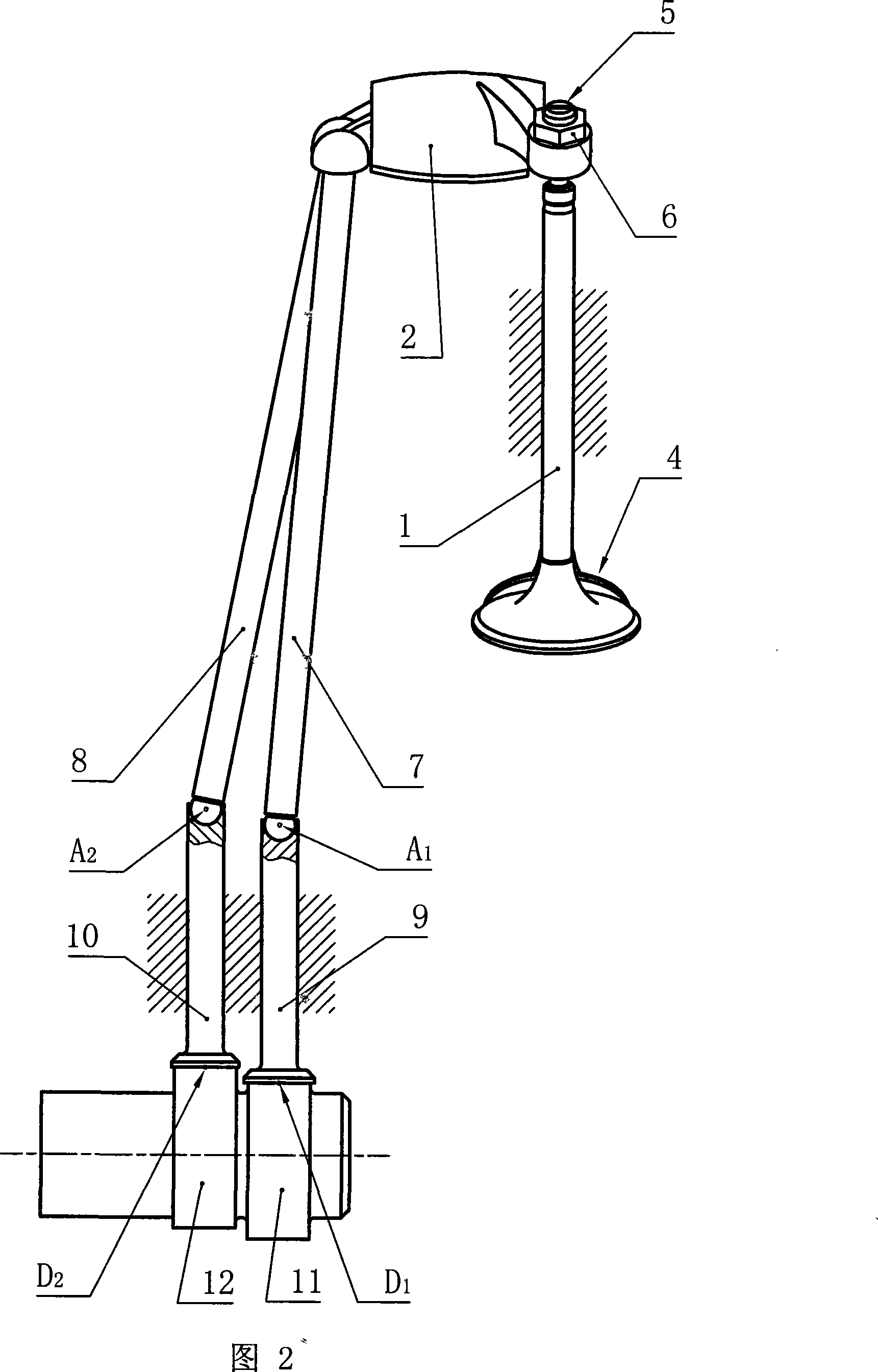

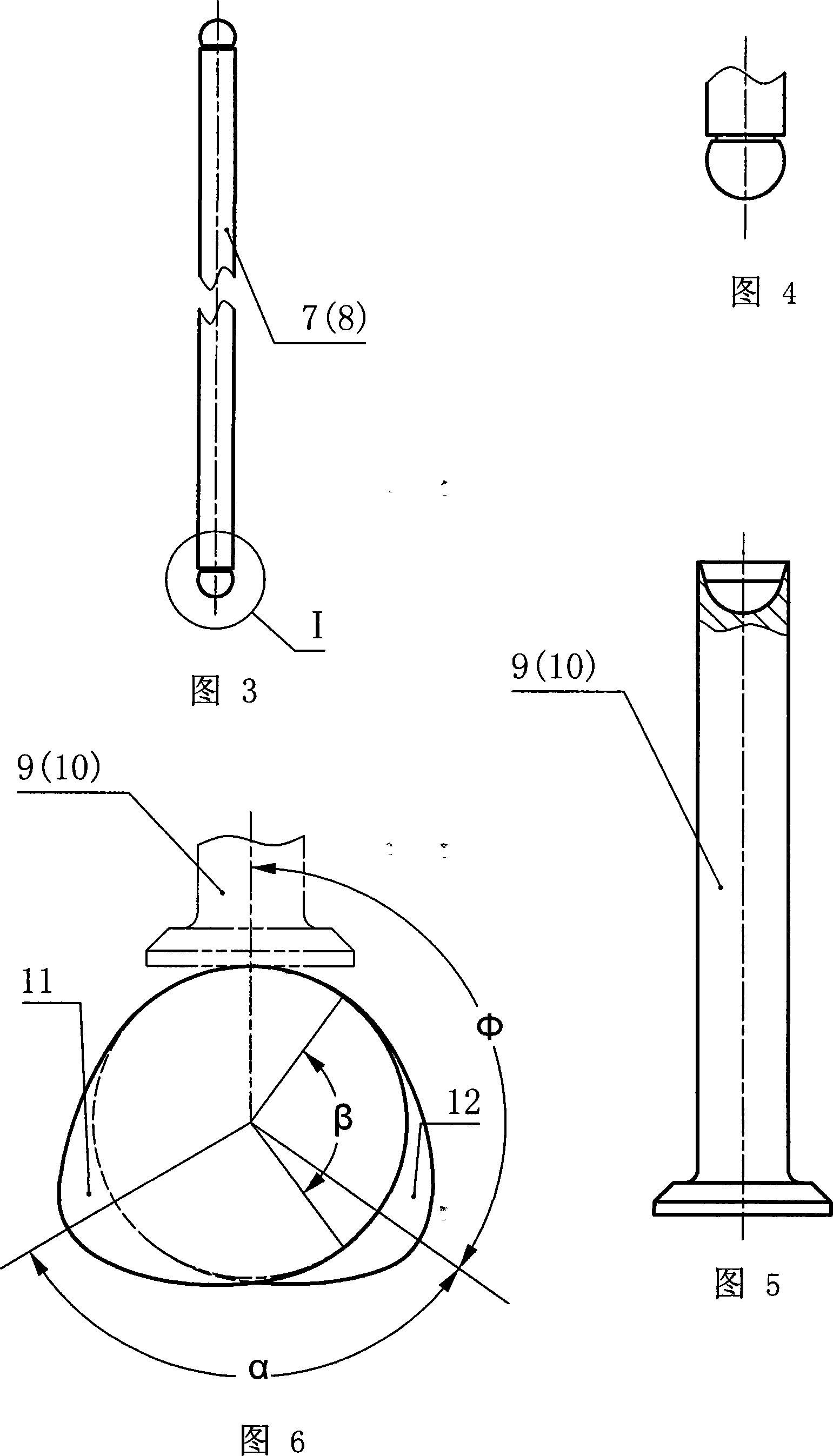

[0025] Disclosed is a camshaft-mounted valve train of a motorcycle engine (refer to Figs. 1-5). The gas distribution mechanism includes a camshaft with a cam on it, finally the intake and exhaust push rods (7, 8) pushed by the cam, and the intake and exhaust push rods (7, 8) respectively pass through the ball joints at the upper ends respectively. The intake and exhaust rocker arms (2, 3) that are connected to one end and push it to swing, the intake and exhaust rocker arms (2, 3) respectively conflict with their tail ends through the adjustment screws 5 on the other ends and push them to open Intake and exhaust valves (1, 4) [after adjusting the adjustment screws 5 respectively, the adjustment screws 5 are locked on the end of the intake and exhaust rocker arms (2, 3) by the lock nut 6]. Each back-moving spring (because it is obvious and is the prior art, so omits and does not draw among the figures) is respectively installed with driving them to close on this inlet and exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com