Method for assembling sleeve tank and inner and outer tank supporting device of cryogenic tank car

A supporting device and assembly method technology, applied in the direction of auxiliary devices, workpiece clamping devices, auxiliary welding equipment, etc., can solve problems such as low work efficiency, supporting leg support structure is not suitable for railway transportation, and cracks are easy to occur at the welding connection position , to achieve the effect of improving work efficiency, improving construction efficiency and quality, and improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

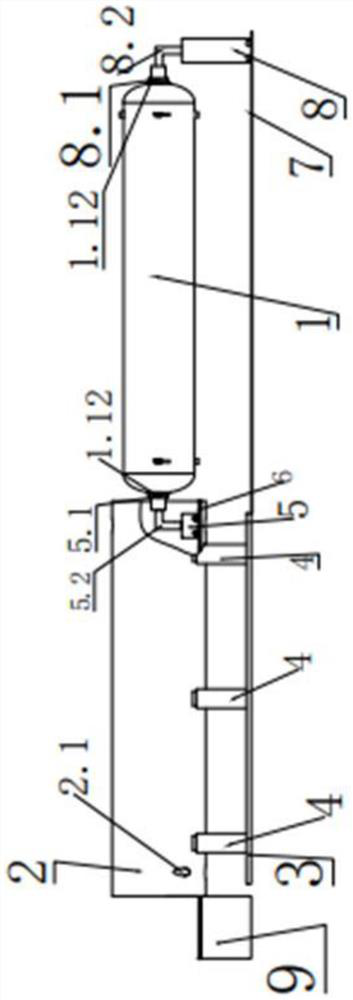

[0134] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0135] The invention provides a method for assembling a cryogenic tank car sleeve and an inner and outer tank supporting device, and the specific steps are as follows:

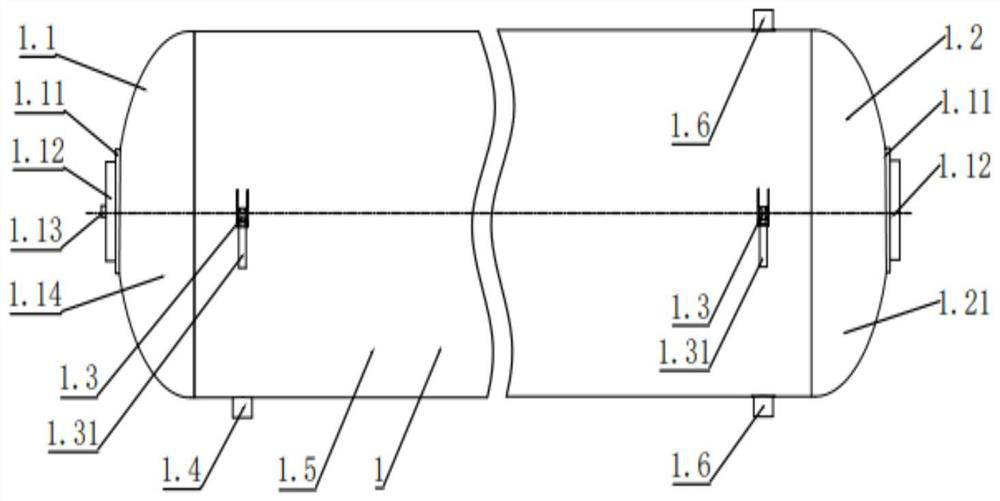

[0136] Step 1, such as figure 1 and figure 2 As shown, the inner tank assembly 1 is assembled and welded.

[0137]Step 1.1, in order to ensure that the 4 inner tank body upper ball joint unit components 1.3 in the inner tank body component 1 are on the same level after being assembled and welded, such as figure 1 As shown, first place a qualified workbench horizontally on the ground of the factory building, and use a spirit level to level the workbench.

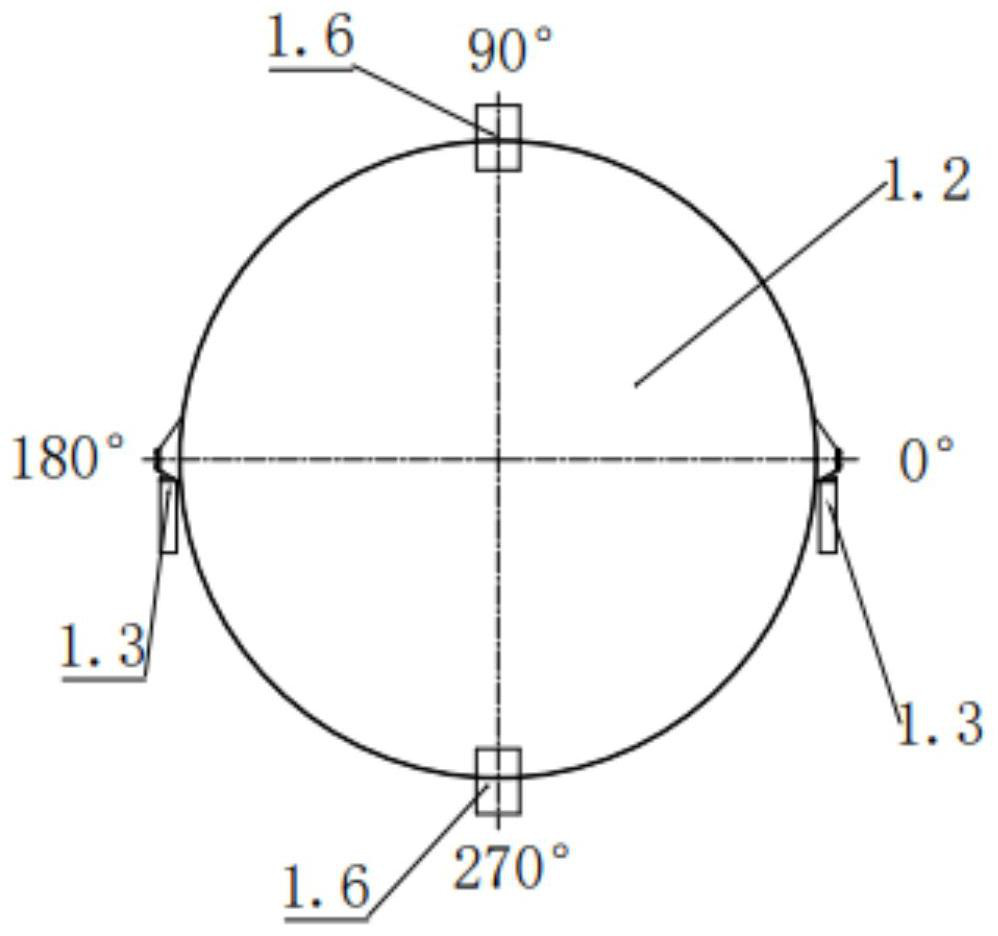

[0138] Step 1.2, place the inner tank body assembly 1.5 welded by several barrel sections on the workbench, draw 0°, 90°, 180°, 0°, 90°, 180°, 270° busbar. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com