Heat converter for outdoor machine of air-conditioner and outdoor aerials using the same

An air conditioner outdoor unit and heat exchanger technology, which is applied in the field of outdoor unit heat exchangers of cooling and heating heat pump type air conditioners, can solve the problems of low heat exchange capacity and effect, and achieves the improvement of cooling effect, obvious heat exchange effect, and increased flow rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

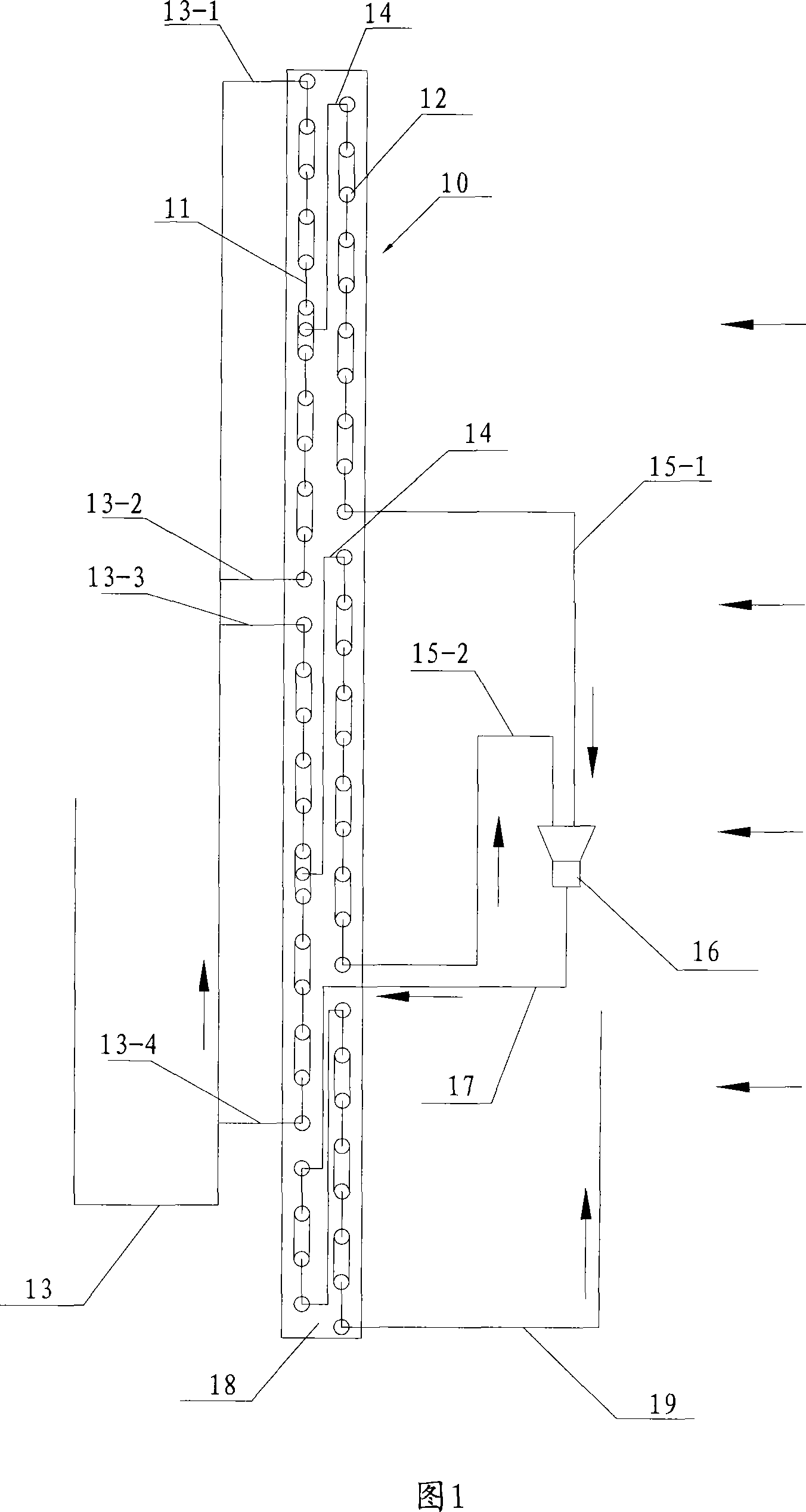

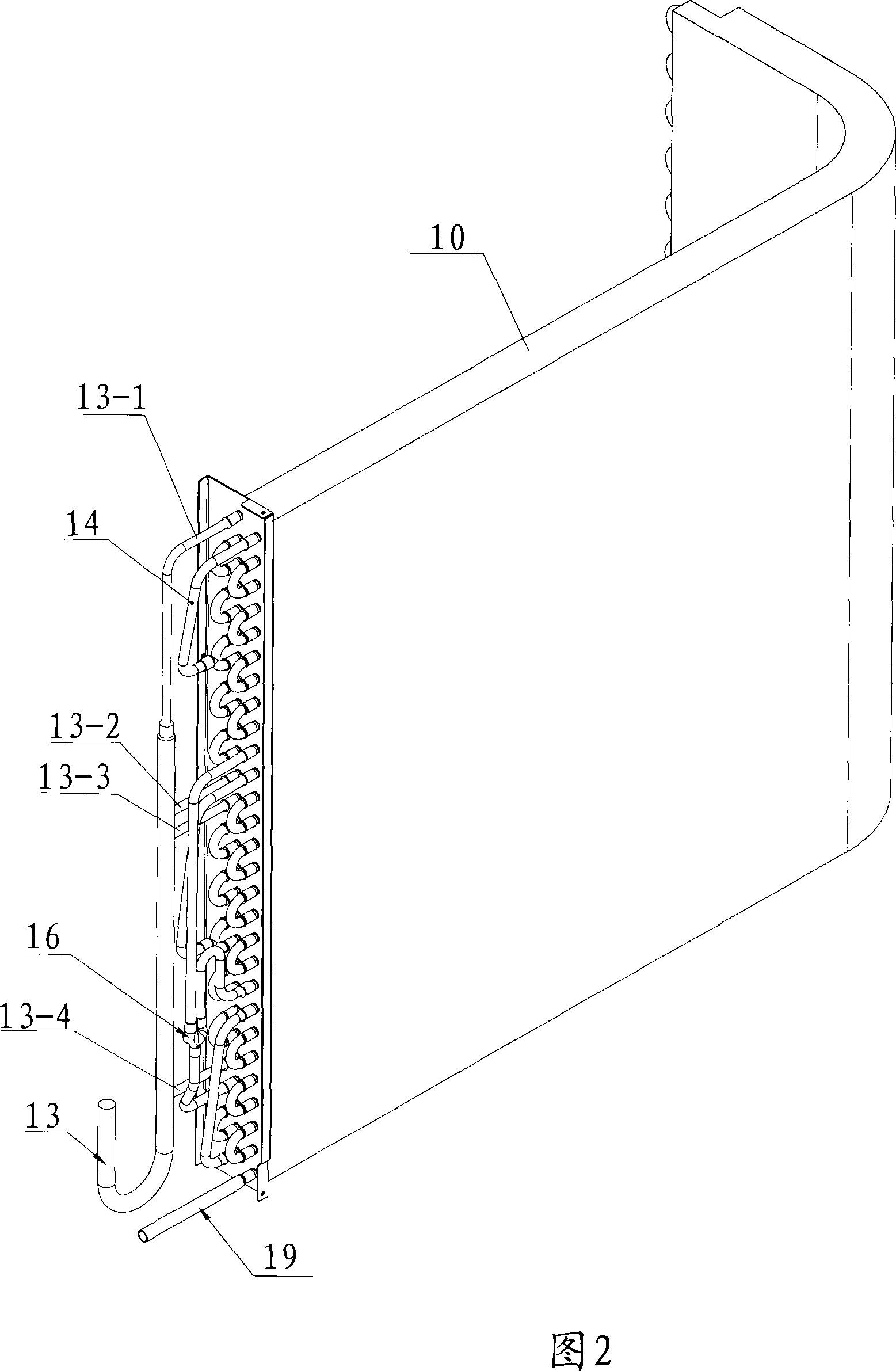

[0020] Referring to Fig. 1 and Fig. 2, the design concept of the present invention is to improve the flow of the refrigerant to increase the flow rate of the refrigerant in the U-shaped tube 12 of the outer heat exchanger, thereby improving the heat exchange effect.

[0021] The refrigerant enters through the inlet pipe 13, and is divided into four channels to form four inlet pipes 13-1, 13-2, 13-3, and 13-4, and enters the U-shaped copper tube 11 of the inner row heat exchanger. After the same number of U-shaped copper tubes 11 of the inner row heat exchanger, for example, 3 U-shaped tubes, enter the U-shaped tube 12 of the outer row heat exchanger through the jumper pipe 14, and the U-shaped tube 11 of the inner row heat exchanger at the confluence The two channels of refrigerant diverge into the outlet ports of the same number of U-shaped tubes, so that the distance of each channel is equal and the heat exchange is balanced. Each path of refrigerant entering the U-shaped tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com