Three-dimensional plastic sheet

A plastic sheet, three-dimensional technology, applied in the field of three-dimensional plastic sheets, can solve the problems of blurred vision, moiré, and no high resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

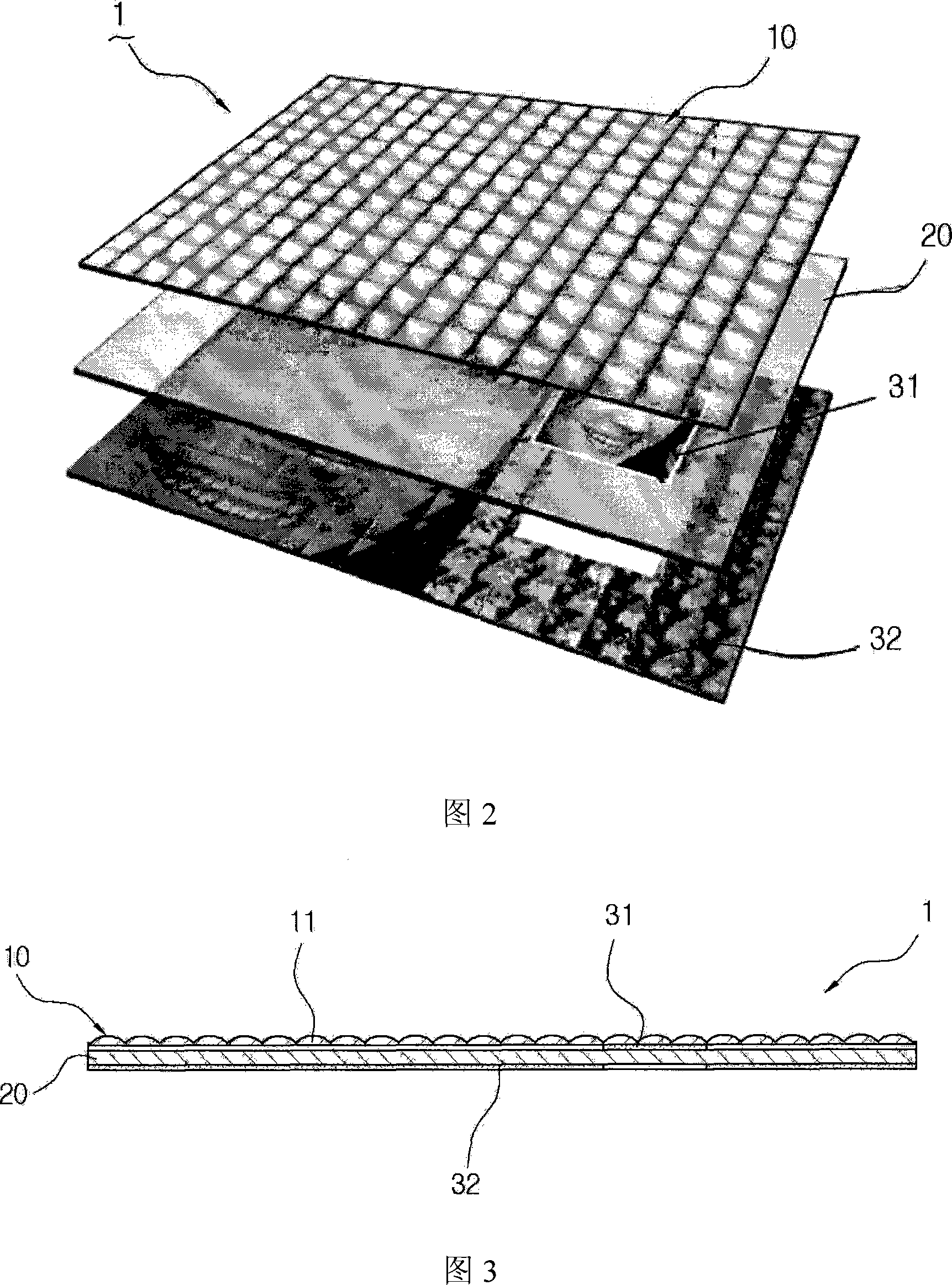

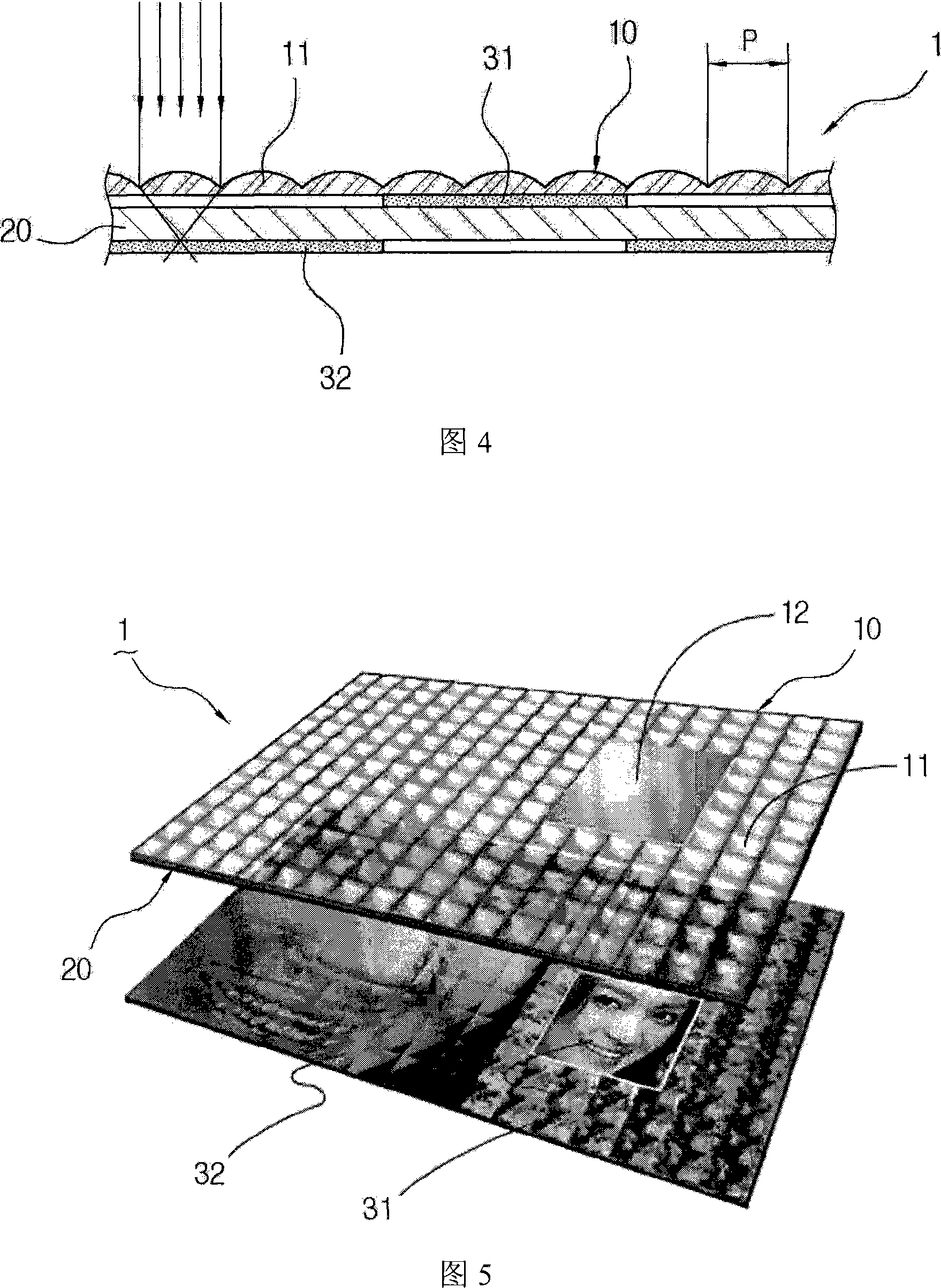

[0025] The following drawings show a preferred embodiment of the structure of the present invention. First, the reference numerals of each component indicate the same numerals in explaining other drawings.

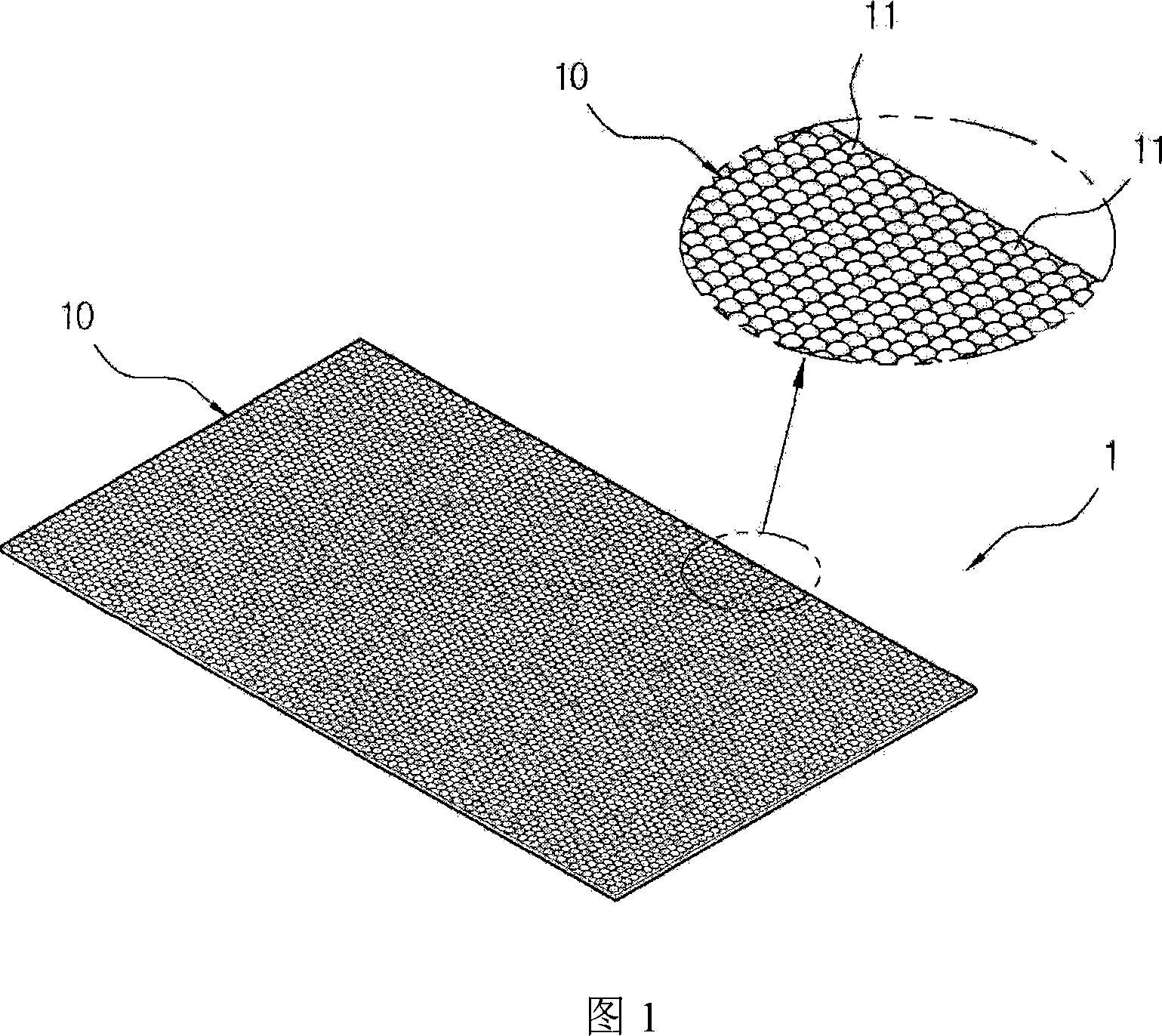

[0026] As shown in FIGS. 1 to 4 , the lenticular lens layer 10 is arranged on the uppermost layer of the three-dimensional plastic sheet 1 .

[0027] The lenticular lens layer 10 is molded from transparent synthetic resin by forming a series of identical hemispherical lenticular lenses 11 vertically and horizontally on the top surface of the lenticular lens layer 10 .

[0028] As shown in FIG. 9 , the lenticular lenses 11 of the lenticular lens layer 10 are arranged at an inclination angle of 45° such that imaginary lines passing through the centers of the lenticular lenses 11 have an intersection angle of 90°.

[0029] In some cases, as shown in FIG. 10 , the convex lens 11 is arranged at an inclination angle of 60° such that an imaginary line passing through the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com