Directly-down back light module unit

A backlight module and direct-type technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of reducing the thickness of the direct-type backlight module, large induced current, and reduced luminous efficiency of the lamp tube, and achieves a reduction Thickness, reduce the induced current, ensure the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the invention will be further described below in conjunction with the accompanying drawings:

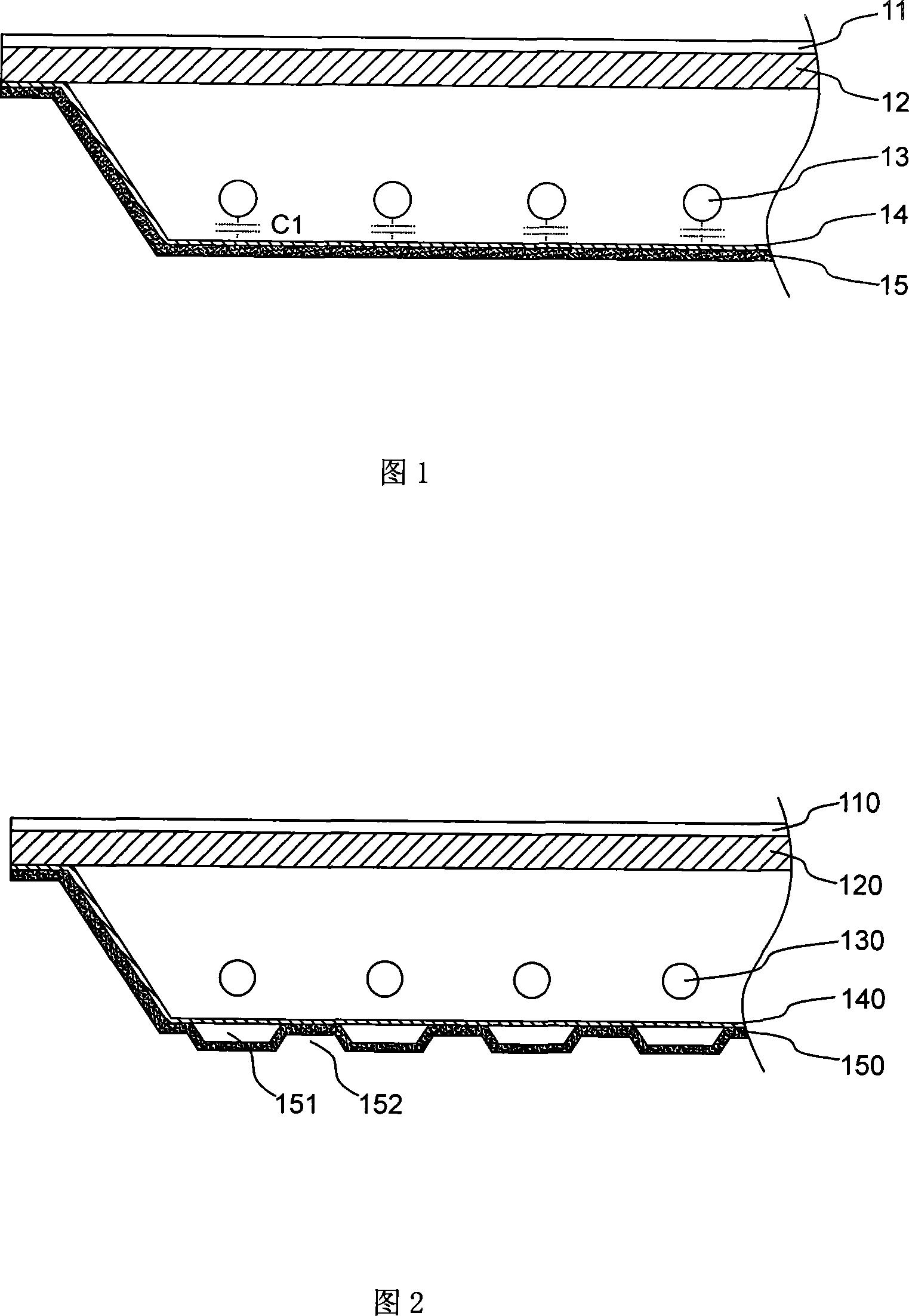

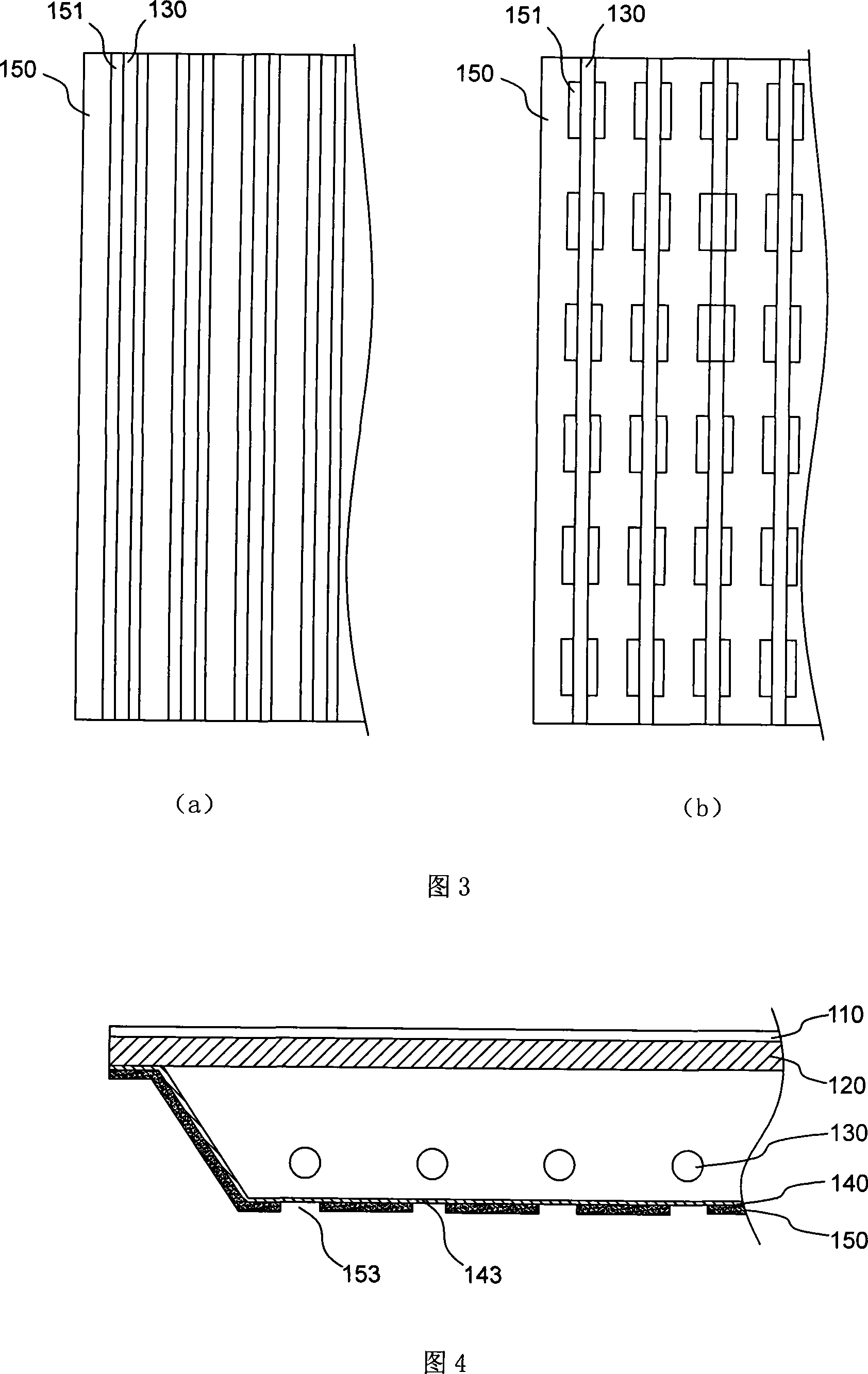

[0020] Fig. 2 is a schematic diagram of an embodiment of the direct-type backlight module of the present invention, as shown in the figure, the direct-type backlight module of the present invention includes: several optical films 110; a diffusion plate 120 placed on the optical film 110; a number of lamp tubes 130 arranged in parallel are placed under the diffusion plate 120; a reflector 140 is placed under the lamp tube 130; a back plate 150 is placed under the reflector 140 for fixing The reflection sheet 140 is supported.

[0021] The back plate 150 below each light tube 130 is bent downward to form a back plate groove 151. In a preferred embodiment, the back plate groove 151 is located directly below the light tube 130, and the back plate groove 151 The cross-sectional shape of the groove is trapezoidal, and the cross-sectional shape of the back plate groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com