High power semiconductor laser device coupling packaging component

A technology for packaging components and lasers, which is applied to semiconductor lasers, structural details of semiconductor lasers, laser components, etc., can solve problems such as low fiber coupling efficiency, low power density, and laser damage, so as to improve fiber coupling efficiency and reduce reflection The influence of light, the effect of ensuring work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

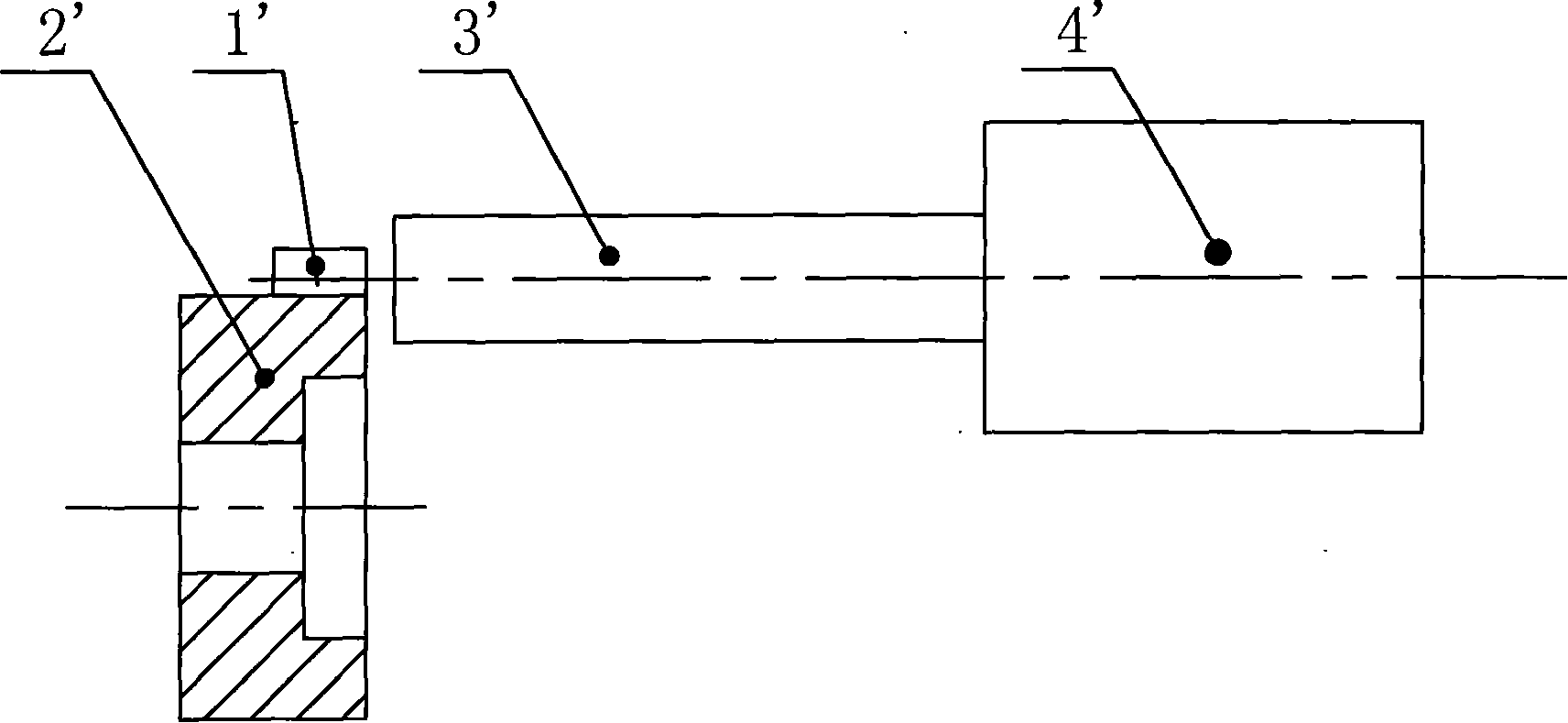

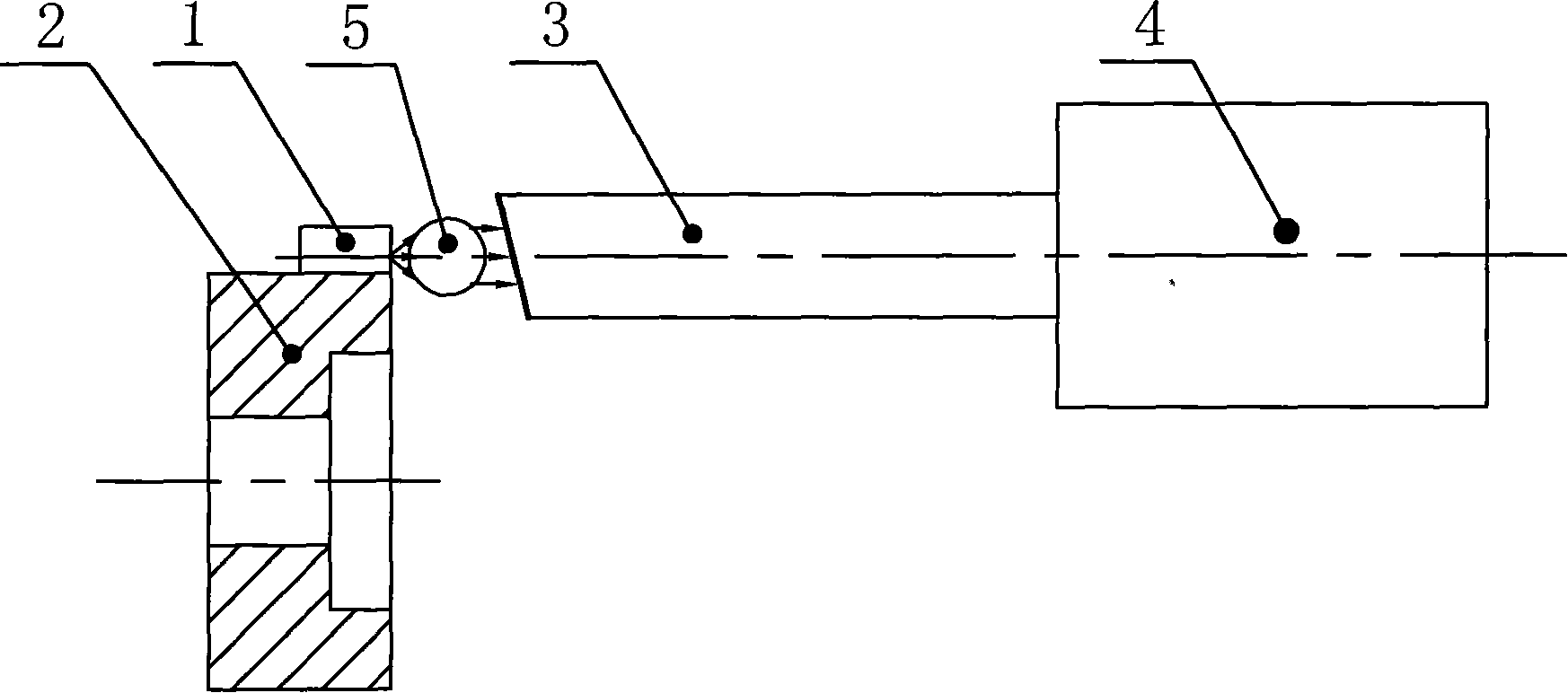

[0020] refer to figure 2 As shown, a high-power semiconductor laser coupling package assembly includes a C-Mount package laser emitting laser, a transmission fiber 3 and an optical fiber connector 4, and the C-Mount package laser includes a heat sink 2 and is fixed on the heat sink The laser light-emitting chip 1 on 2 and the fiber connector 4 are connected to one end of the transmission fiber 3. The laser light emitted by the laser light-emitting chip 1 is coupled into the transmission fiber 3 and then output from the fiber connector 4 at one end of the transmission fiber 3. Among them, a cylindrical lens 5 is arranged between the emitting end of the laser (that is, the light-emitting end of the laser light-emitting chip 1), the end of the transmission fiber 3 and the laser coupling, and the cylindrical lens 5 is used to compress the laser li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com