Series battery charge up circuit with charge compensate function

A technology of connecting battery packs and charging circuits in series, which is used in the charging control of large-capacity power batteries, and electrical appliance control. Achieve the effect of improving charging and discharging efficiency and improving power conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

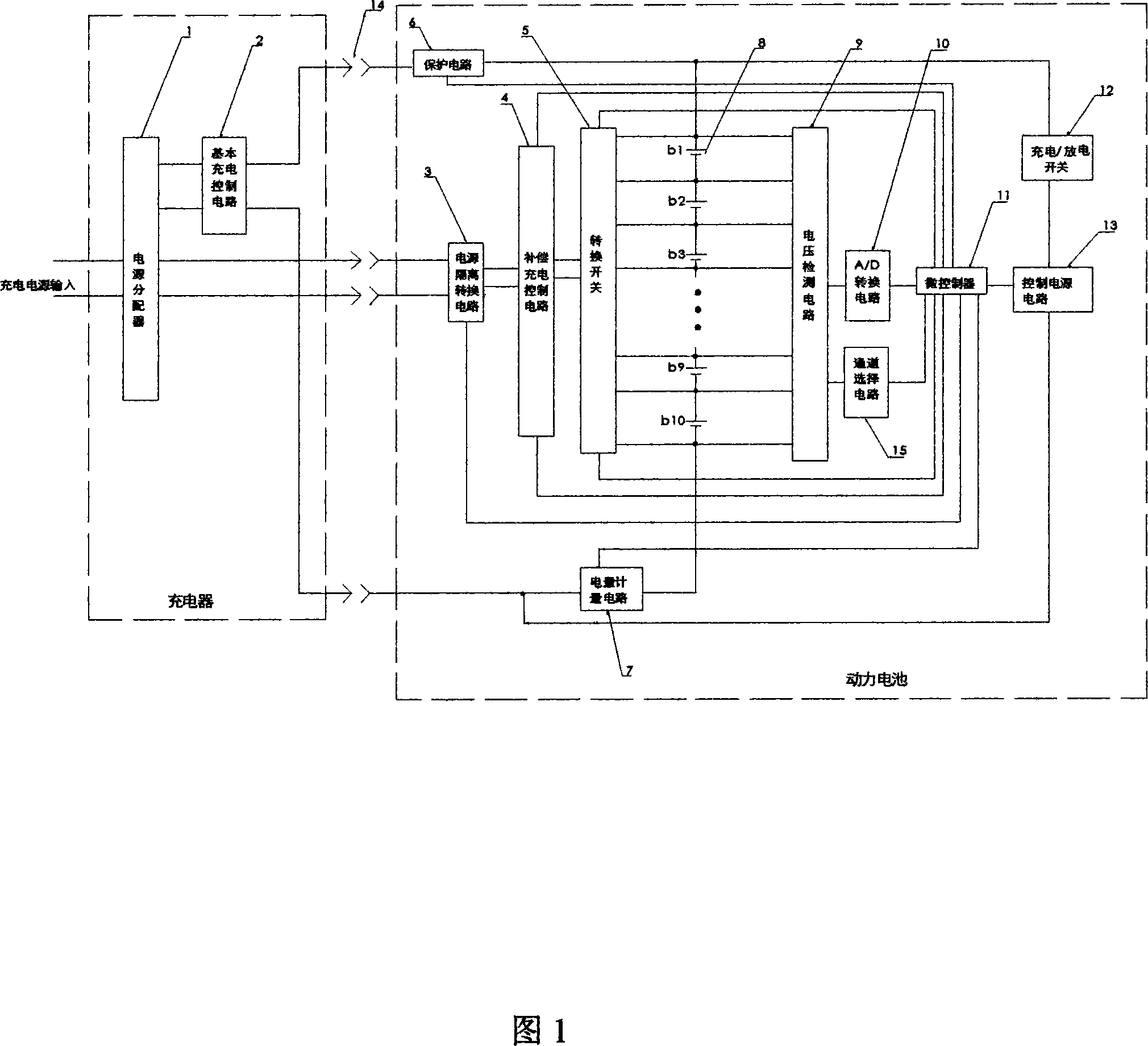

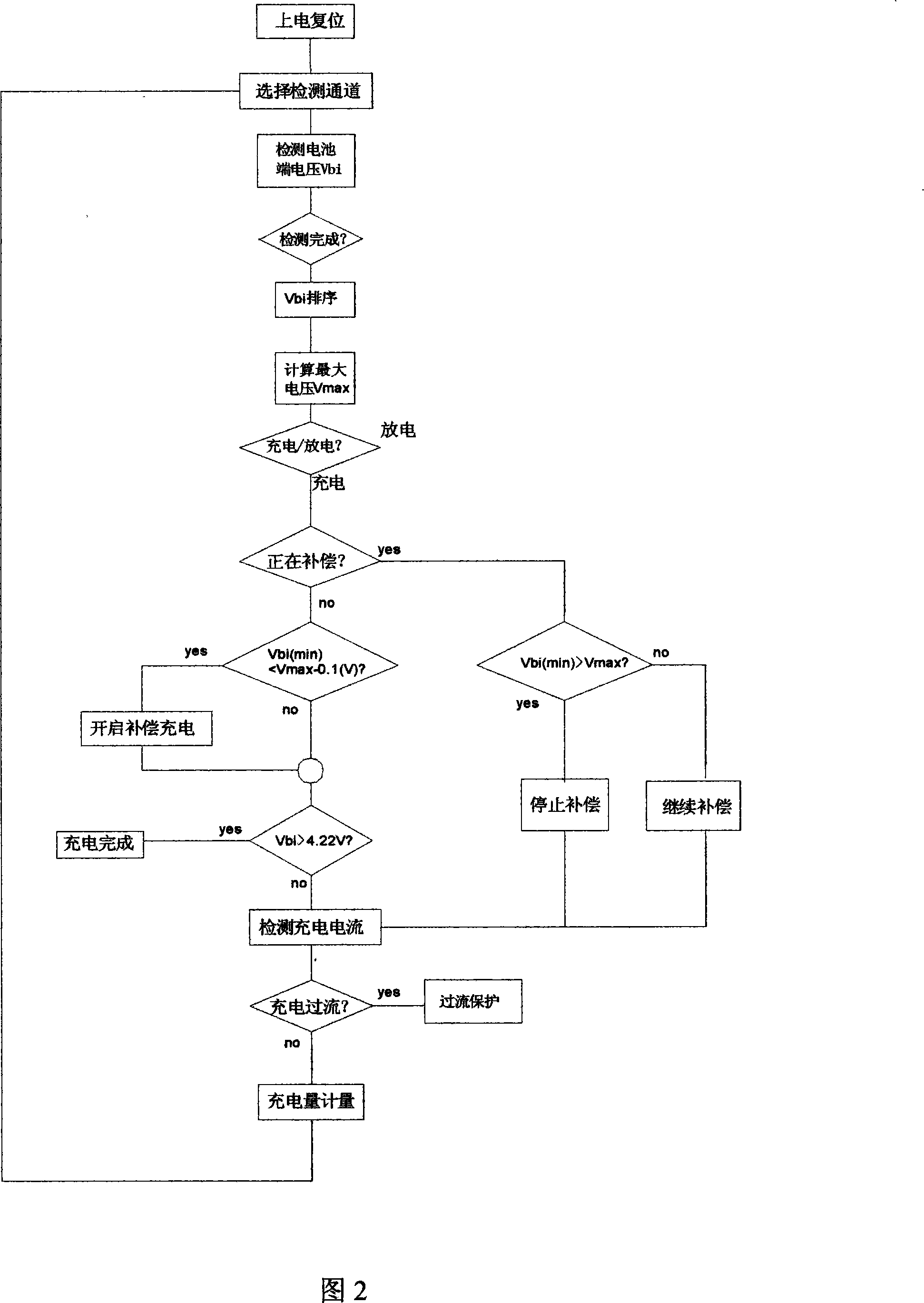

[0022] The implementation method is as follows, see Figure 1 and Figure 2:

[0023] (1) The power distributor 1 adopts a copper connection terminal with a capacity of 5A, and supplies the input power to the basic charging control circuit 2 and the power isolation conversion circuit 3 respectively.

[0024] (2) The basic charging control circuit 2 is composed of an AC / DC converter of AC220V / DC48V15A and a high-power field effect transistor MTB30P06 to form a constant current control circuit to provide a basic charging current of 10A to the series battery pack 8 .

[0025] (3) The power isolation conversion circuit 3 uses an AC200V / 5V20W power isolation transformer and a 5A bridge full-wave rectification circuit to convert the AC220V charging power into a suspended DC5V DC power supply.

[0026] (4) Compensation charging control circuit 4 uses field effect transistor NTMS10P02 as a constant current control element, and the output current is constant at 2A.

[0027] (5) The tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com