High speed bend test device

A bending test, high-speed technology, used in the testing of measuring devices, machines/structural components, and the use of repetitive force/pulse force to test the strength of materials, etc. , easy to adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

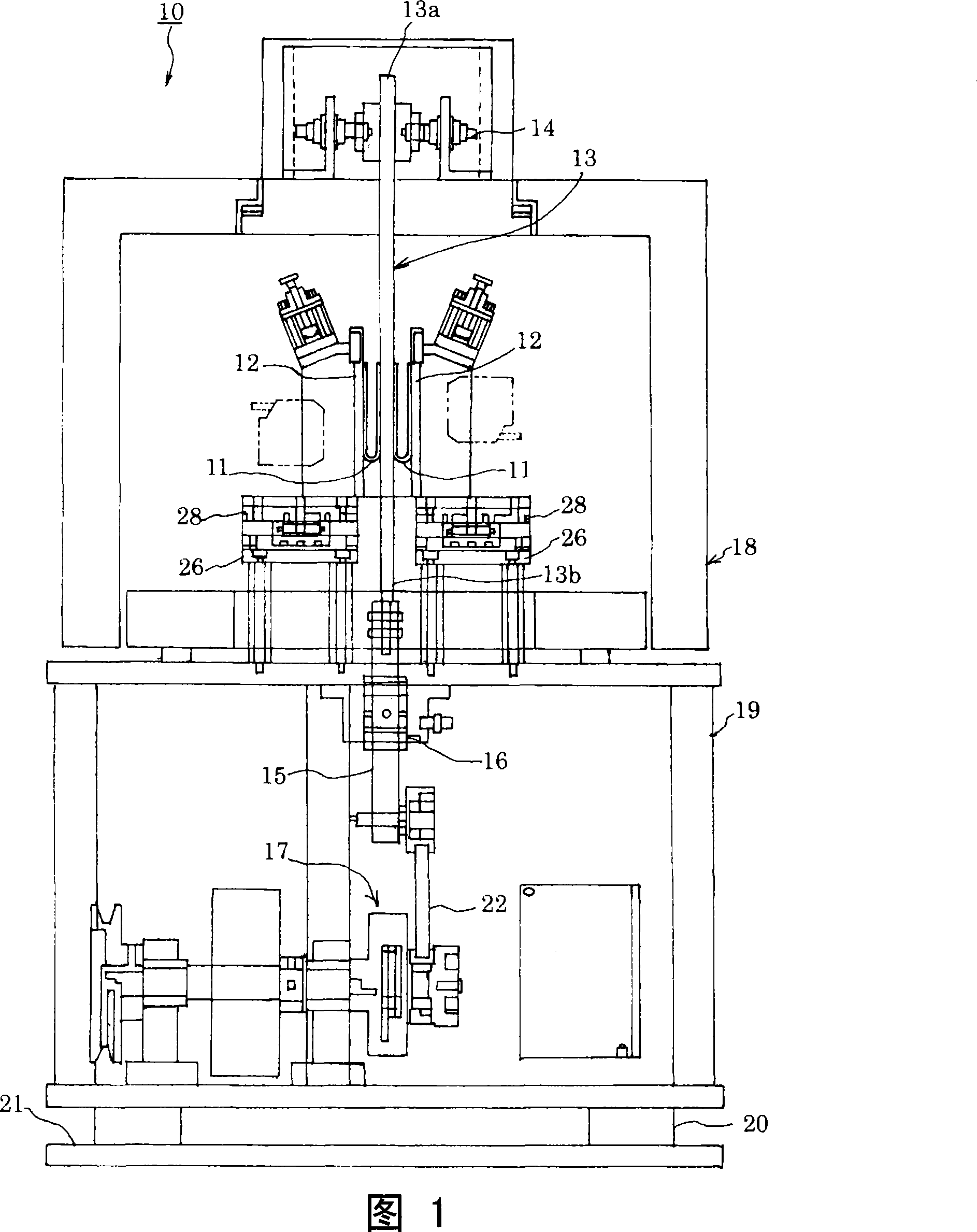

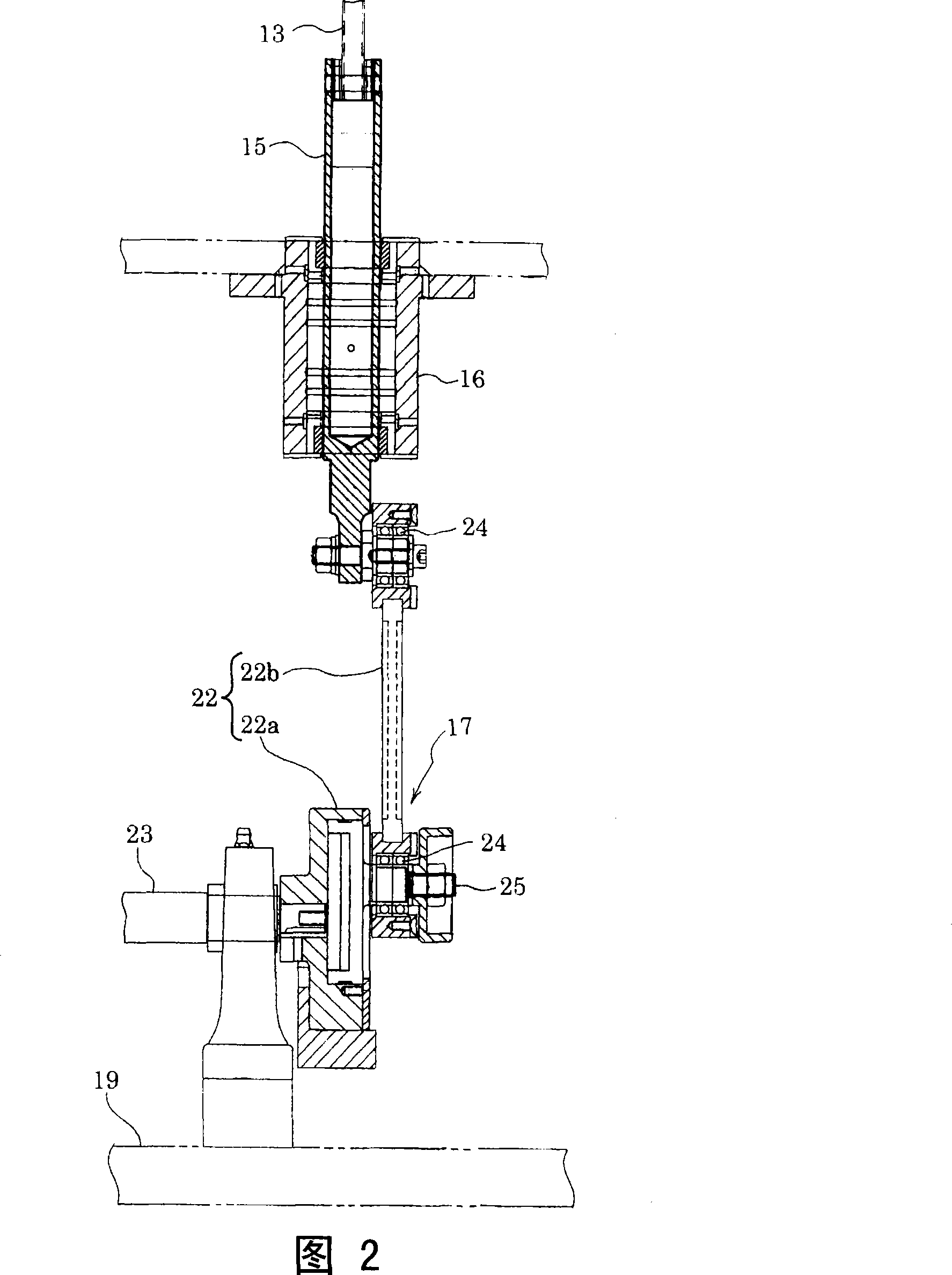

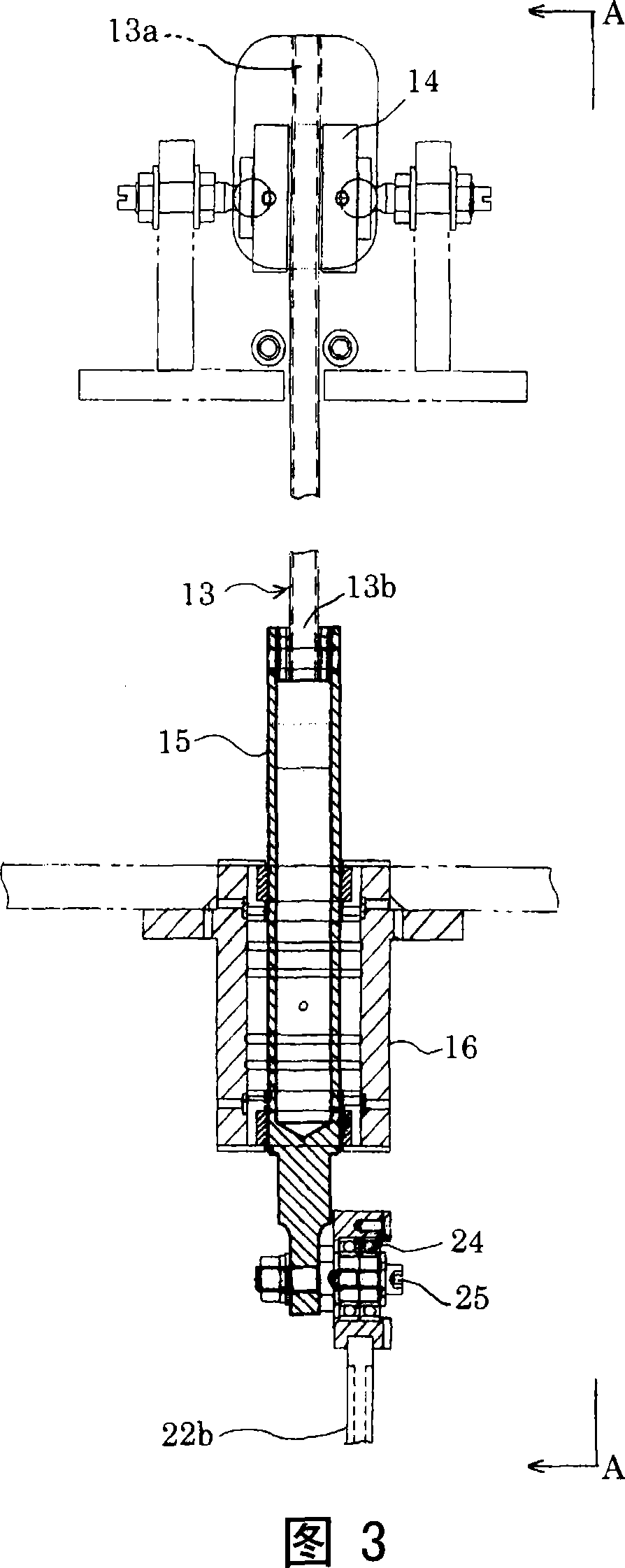

[0027] FIG. 1 is an overall structural diagram of the high-speed bending test apparatus of the present invention. A high-speed bending test apparatus (hereinafter simply referred to as a "test apparatus") 10 is composed of the following components and the like: a pair of left and right fixing plates 12 to which one end portion of the flexible printed circuit board 11 to be bent is fixed; The left and right fixed plates 12 are arranged in parallel with the fixed plate 12 at a predetermined distance, and the other end of the flexible printed circuit board 11 is fixed; the air bearing 14 slidably supports the movable plate 13. One end (in the figure, the top end) 13a; the holder 15 mounted on the other end (in the figure, the bottom end) 13b of the movable plate 13; the air bearing 16, The air bearing 16 slidably supports the holder 15 ; the vibrating body 17 connected to the holder 15 , and the like.

[0028] The flexible printed circuit board 11 that is bent and fixed between ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap