Optical processing structure for digital optical processing projection device

A technology of digital light processing and projection device, which is applied to the image reproducer of projection device, projection device, optics, etc., can solve the problems of increasing difficulty in lens design, back focal length of projection objective lens, and large prism volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

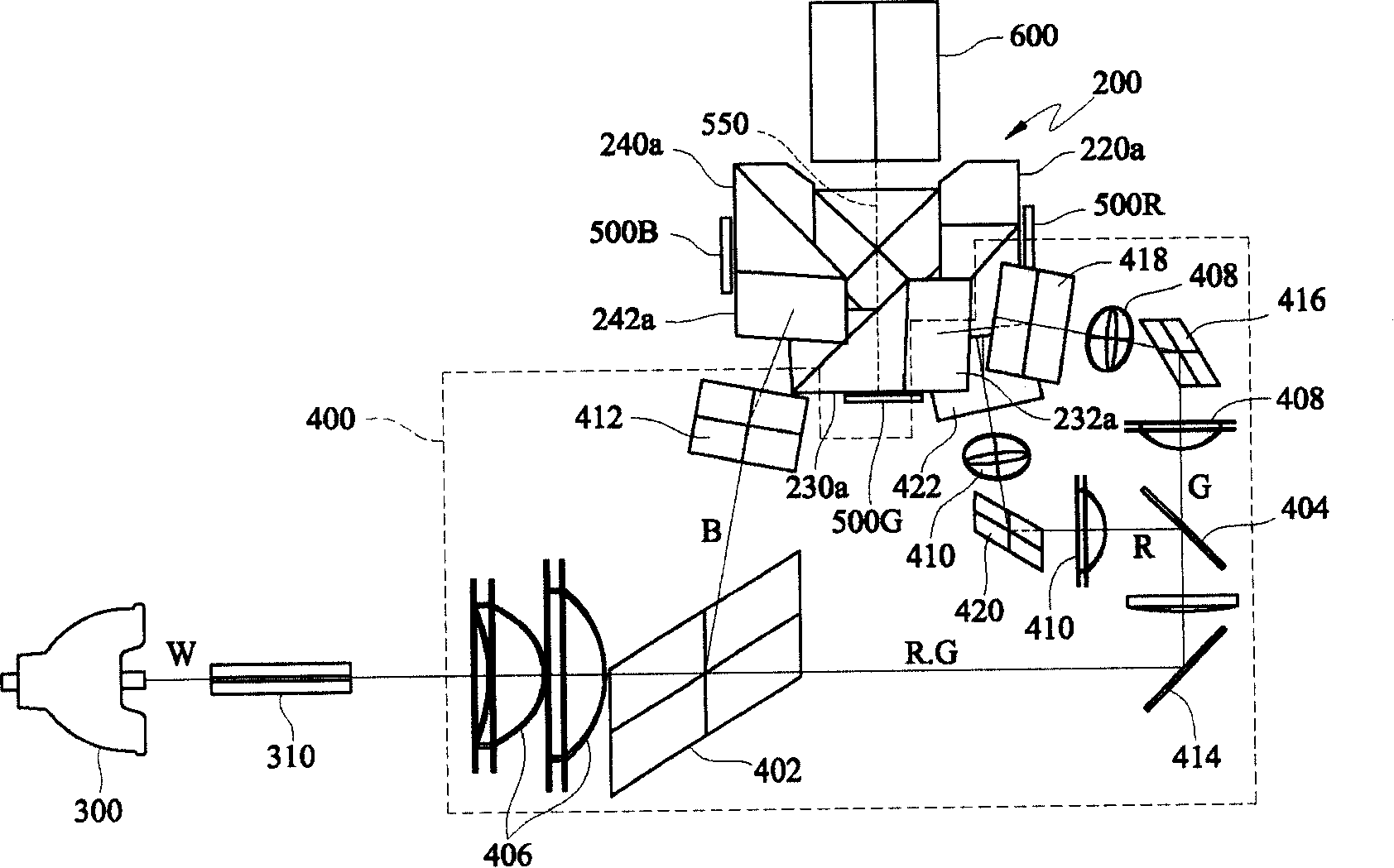

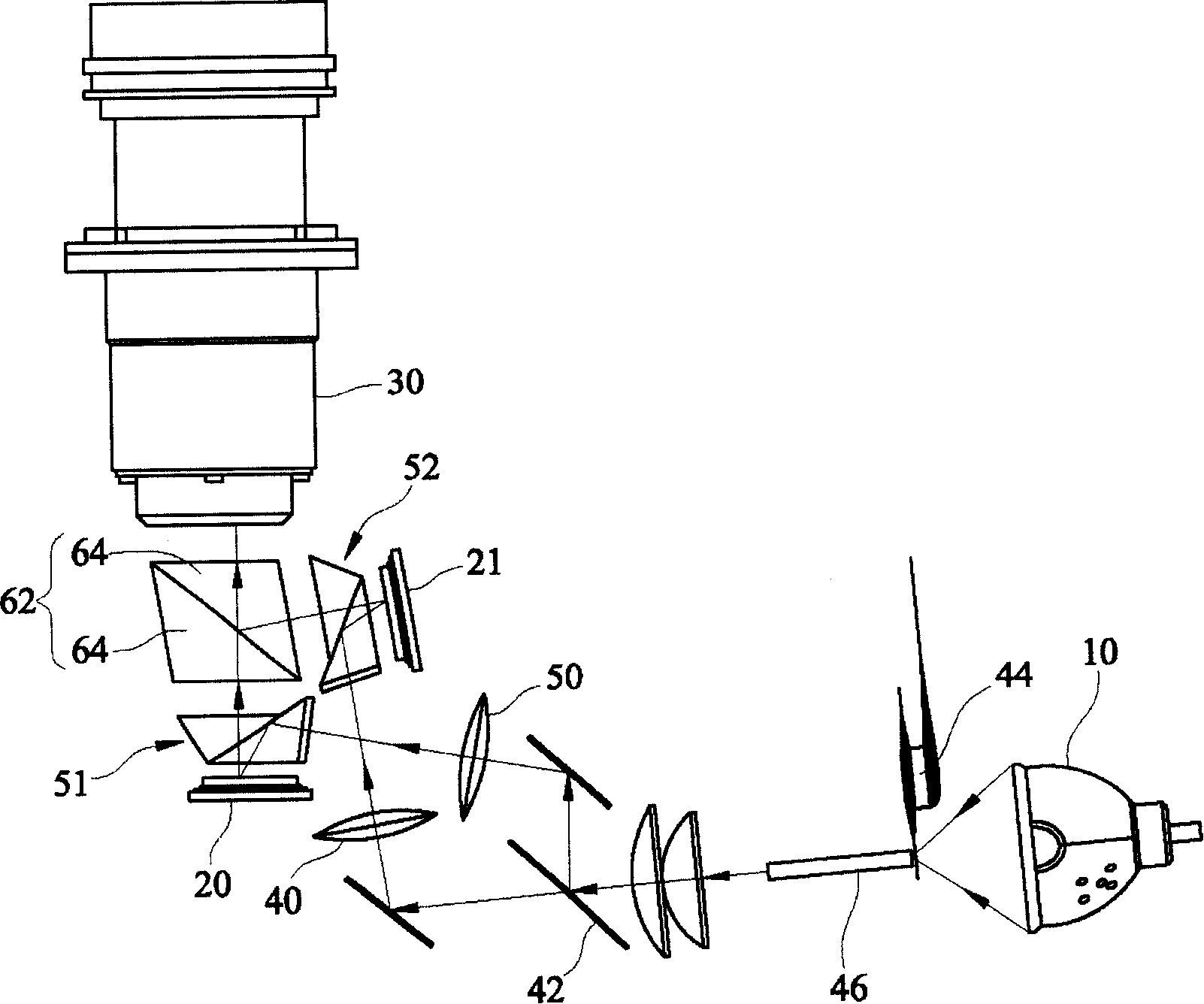

[0038] figure 2 Represents one embodiment of the light processing structure used in the digital light processing projection device of the present invention, wherein the DLP projection device includes a light source 10, a plurality of digital micromirror devices (two digital micromirror devices 20, 21 are shown in the figure) , the projection objective lens 30 and the light processing structure of the present invention. The light processing structure includes a light splitting structure, a reflection structure and a light combining structure.

[0039] In detail, the light splitting structure includes at least one light splitting component for splitting the main incident light emitted by the light source 10 into a plurality of secondary incident lights. In a specific embodiment, the beam splitting component can be a beam splitter 42. According to different light source types and different beam splitting requirements, the beam splitting coating in the beam splitter is used to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com