Surface mounting type electronic components and manufacturing method of the same

A surface-mounted, electronic component technology, used in capacitor manufacturing, fixed capacitor parts, electrical components, etc., can solve the problems of cost, difficulty in handling, and difficulty in obtaining laminated ceramic capacitors, and achieves excellent mountability, improved Effect of Plating Adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the surface mount type electronic component of the present invention will be described below by taking a laminated ceramic capacitor as an example. In addition, the present invention is particularly applicable to composite electronic components having a capacitor portion, such as capacitor arrays and LC filters, in addition to laminated ceramic capacitors.

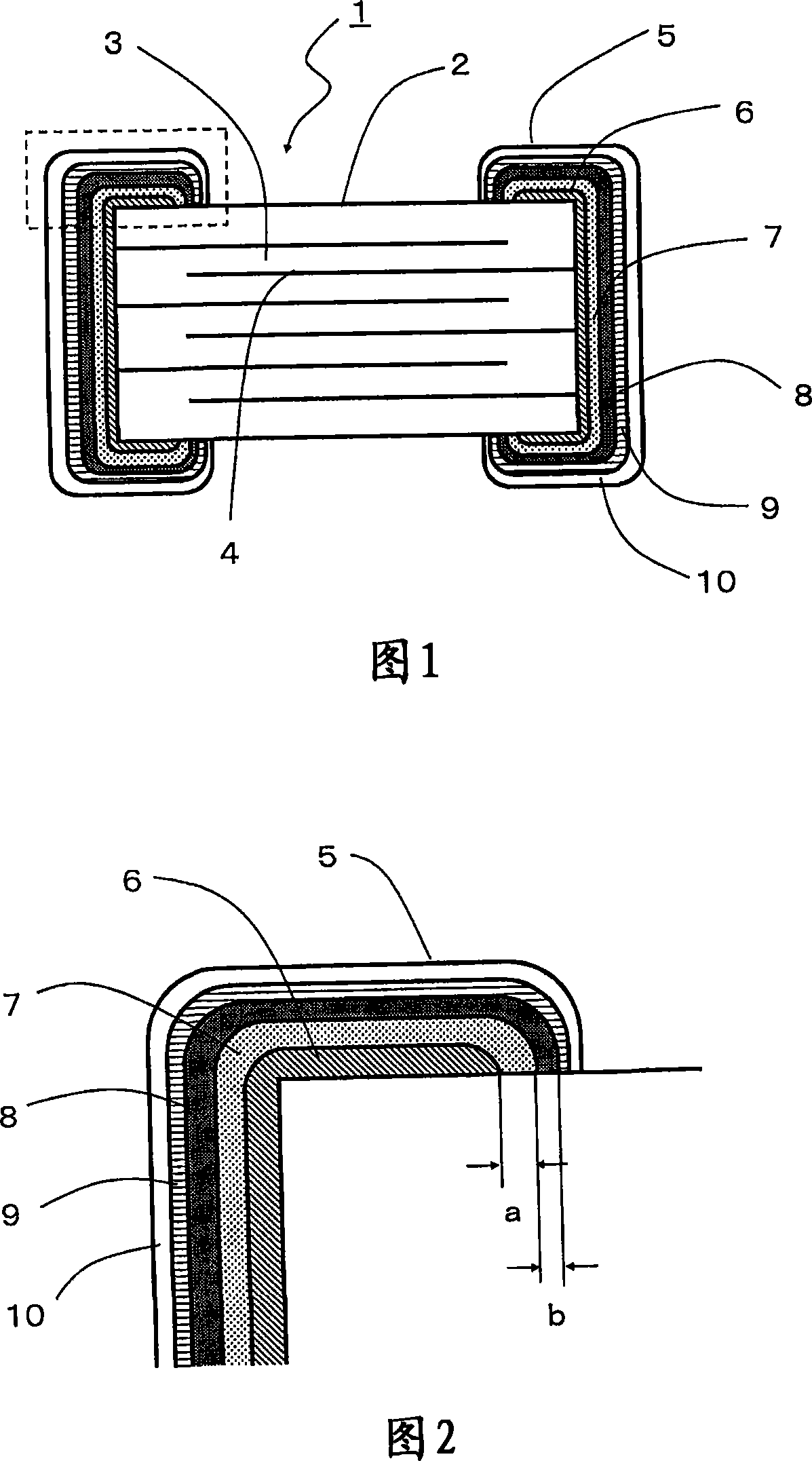

[0033] Fig. 1 is a schematic longitudinal sectional view showing a multilayer ceramic capacitor of the present invention. This multilayer ceramic capacitor 1 has a structure in which a pair of external electrodes 5 are formed on an electronic component base 2 formed by alternately stacking internal electrodes 4 with a ceramic dielectric 3 mainly composed of barium titanate. . The above-mentioned external electrode 5 has a base metal layer 6 closely bonded to the electronic component substrate 2 and electrically connected to the internal electrode 4, has a first resin layer 7 formed on the base metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com