High-power double burner for gas cookers, with multiple concentric flame crowns

A dual-combustion, flame furnace technology, applied in the direction of gas fuel burners, burners, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

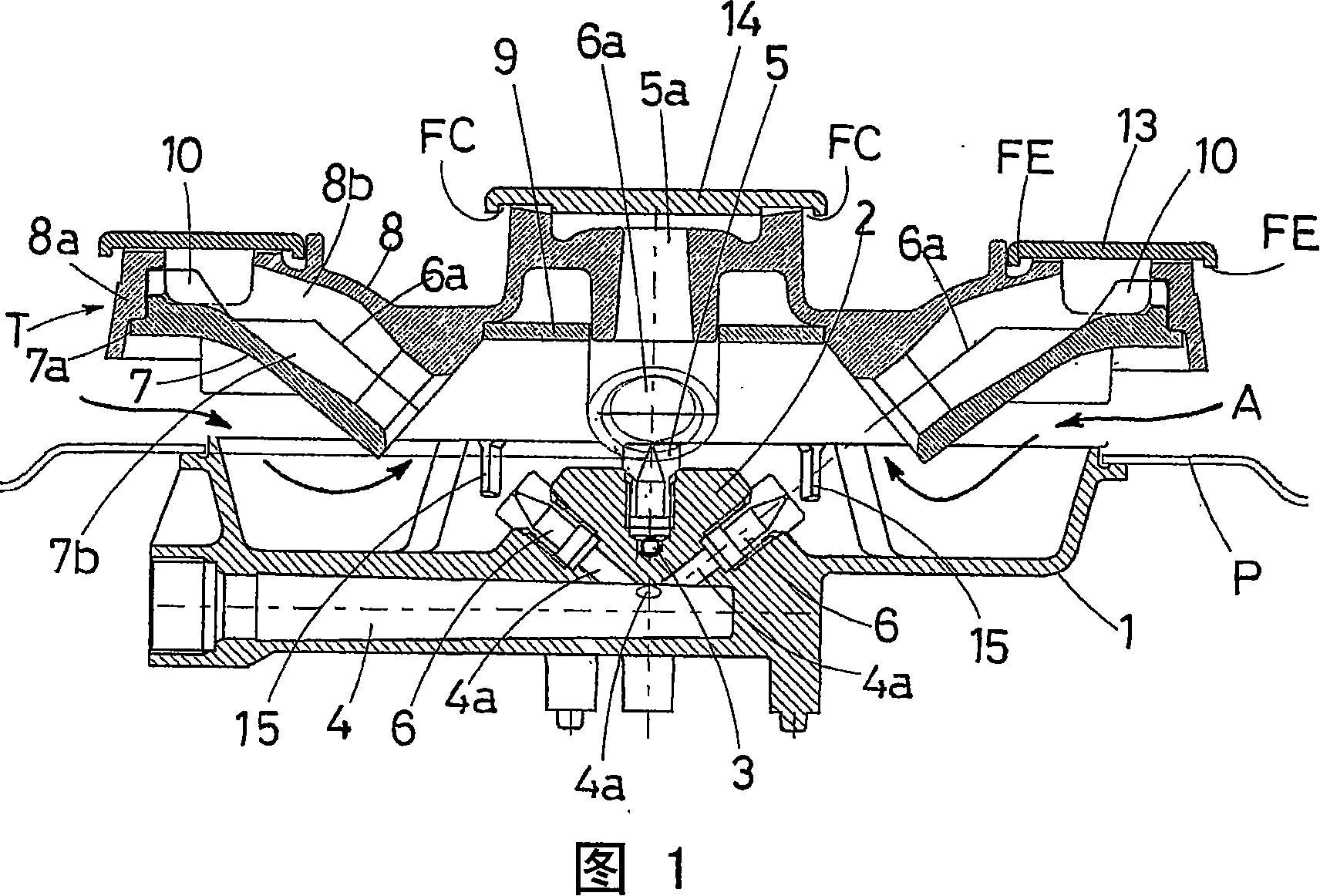

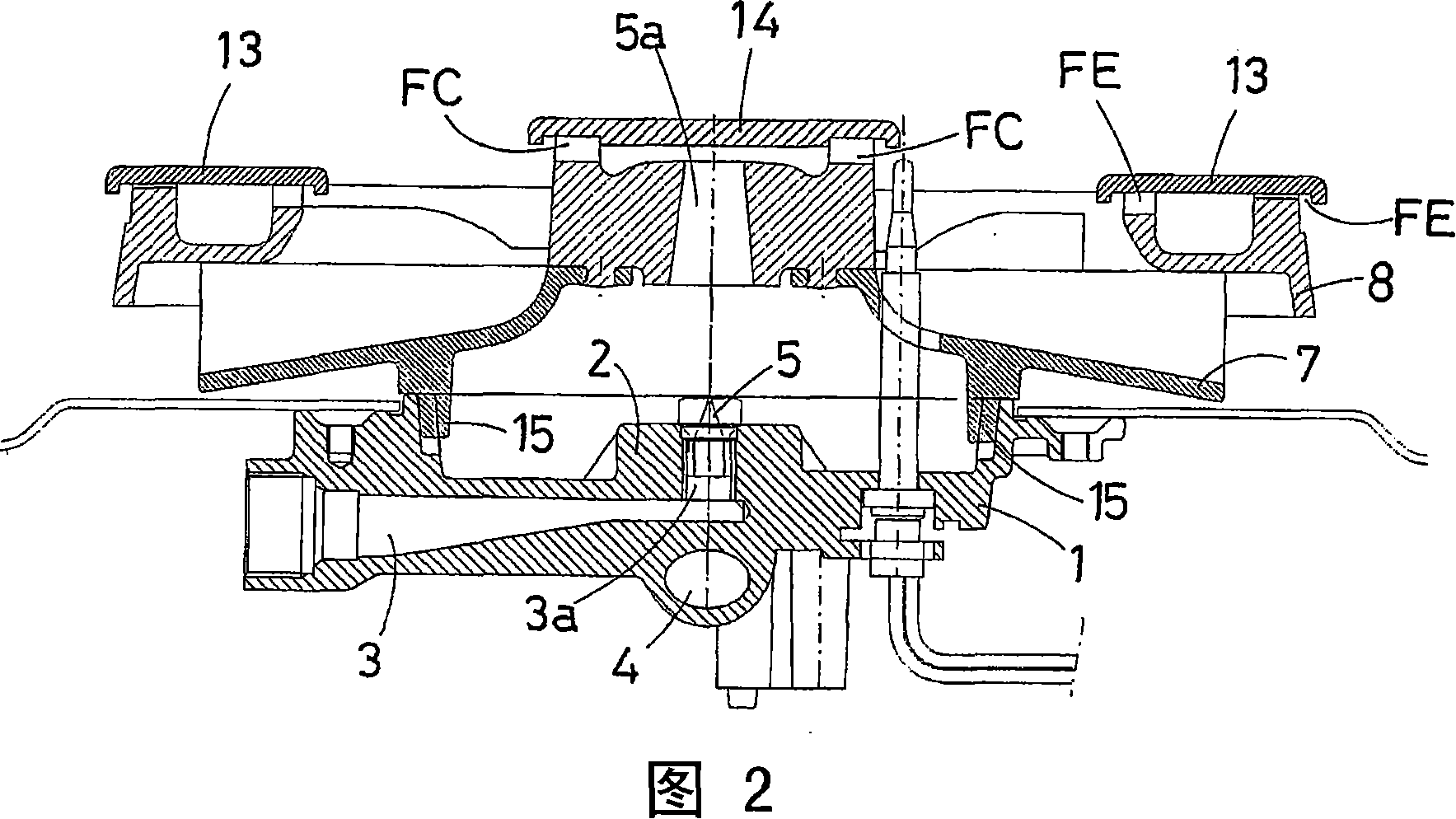

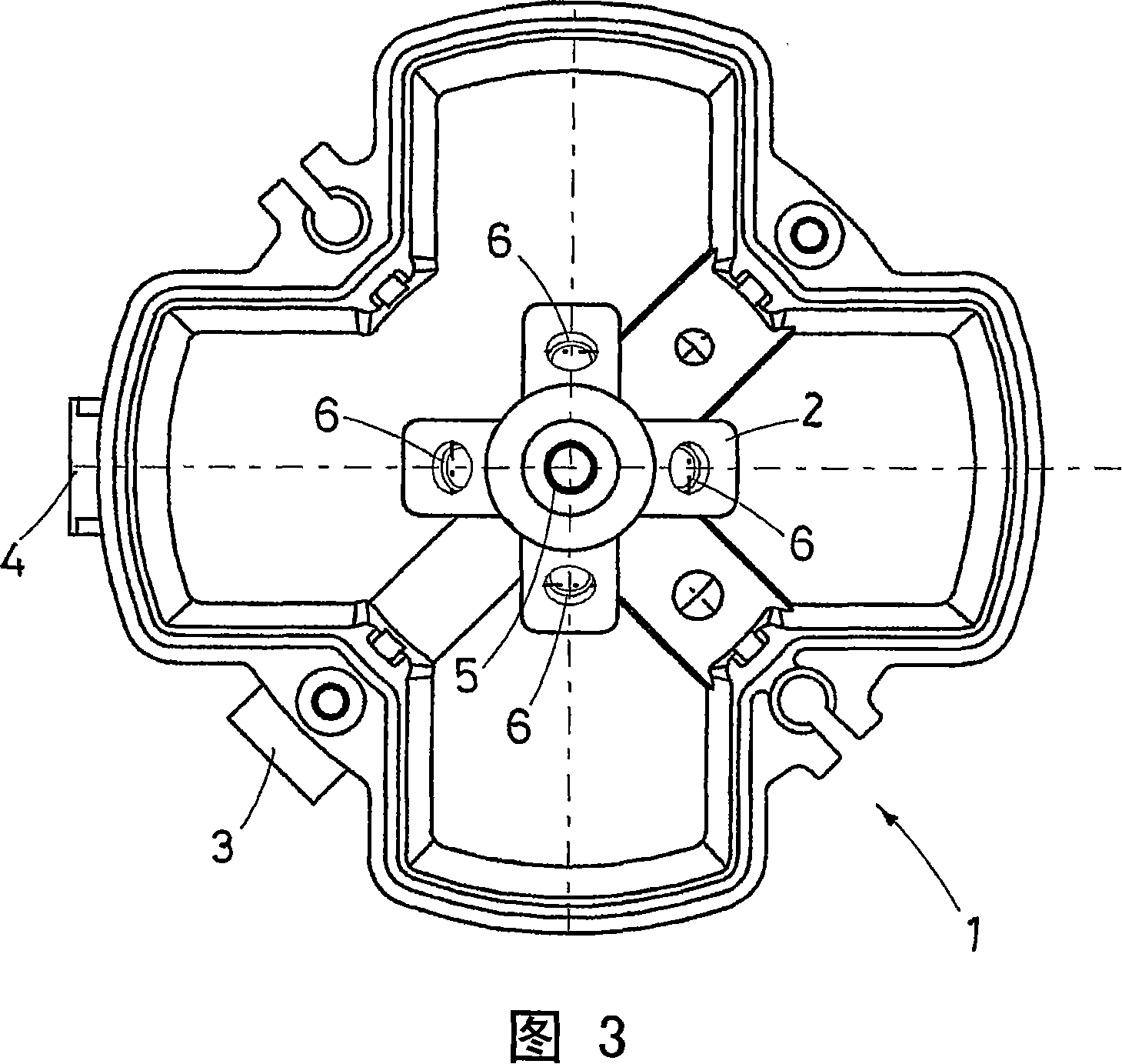

[0026] With reference to the above figures, the double burner of the present invention comprises a circular basin-shaped body 1 housing a raised central crosspiece 2 on which there are housings for a plurality of gas nozzles.

[0027] The main body 1 generally houses two distinct and disconnected gas inlet ducts 3 and 4, each of which can selectively and separately feed the nozzles connected to the centrally fired crown and the nozzles connected to the peripheral fired crown Group.

[0028] The two gas inlet ducts 3 and 4 reach the center of the body 1 at slightly different heights; more precisely, the upper inlet duct 3 ends exactly in the center of the body 1, while the lower inlet duct 4 passes above the center, as shown in Fig. 1.

[0029] A vertical channel 3a branching upwards from the upper gas inlet duct 3, on which is mounted a first nozzle 5 designed to introduce the gas into the venturi mixing chamber that feeds the central flame crown FC; at the same time, Branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com