Method for processing two column internal ball tracks by one grinding

A technology for inner raceway and grinding, which is applied in metal processing equipment, grinding machines, manufacturing tools, etc. It can solve the problems of prolonging processing time, poor processing quality, and reducing the utilization efficiency of grinding wheels, so as to improve processing efficiency and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

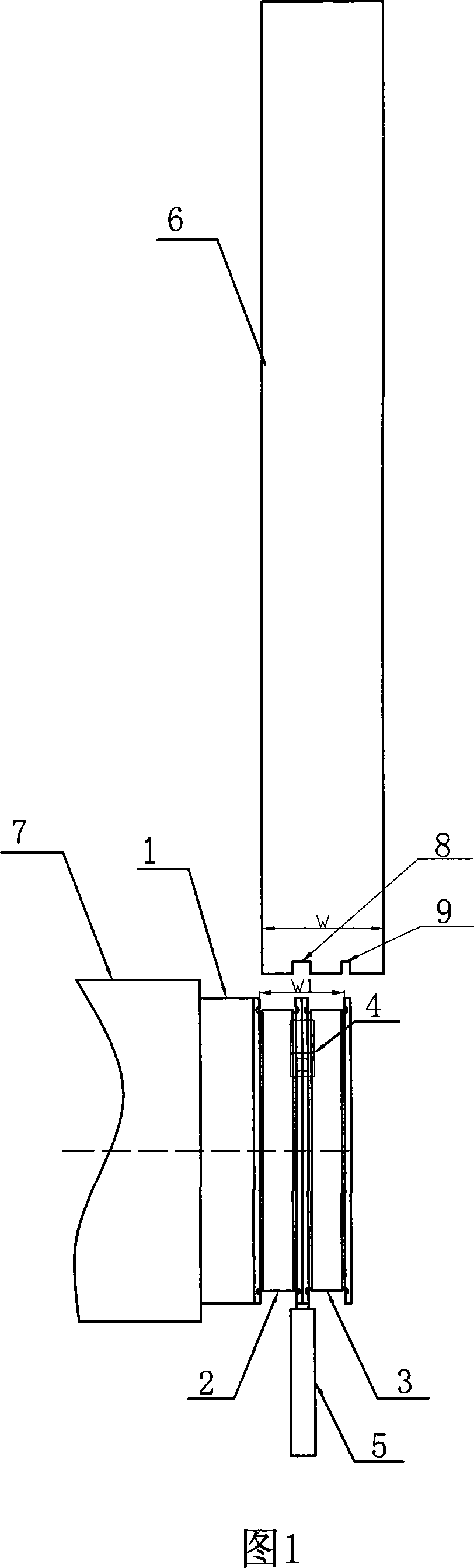

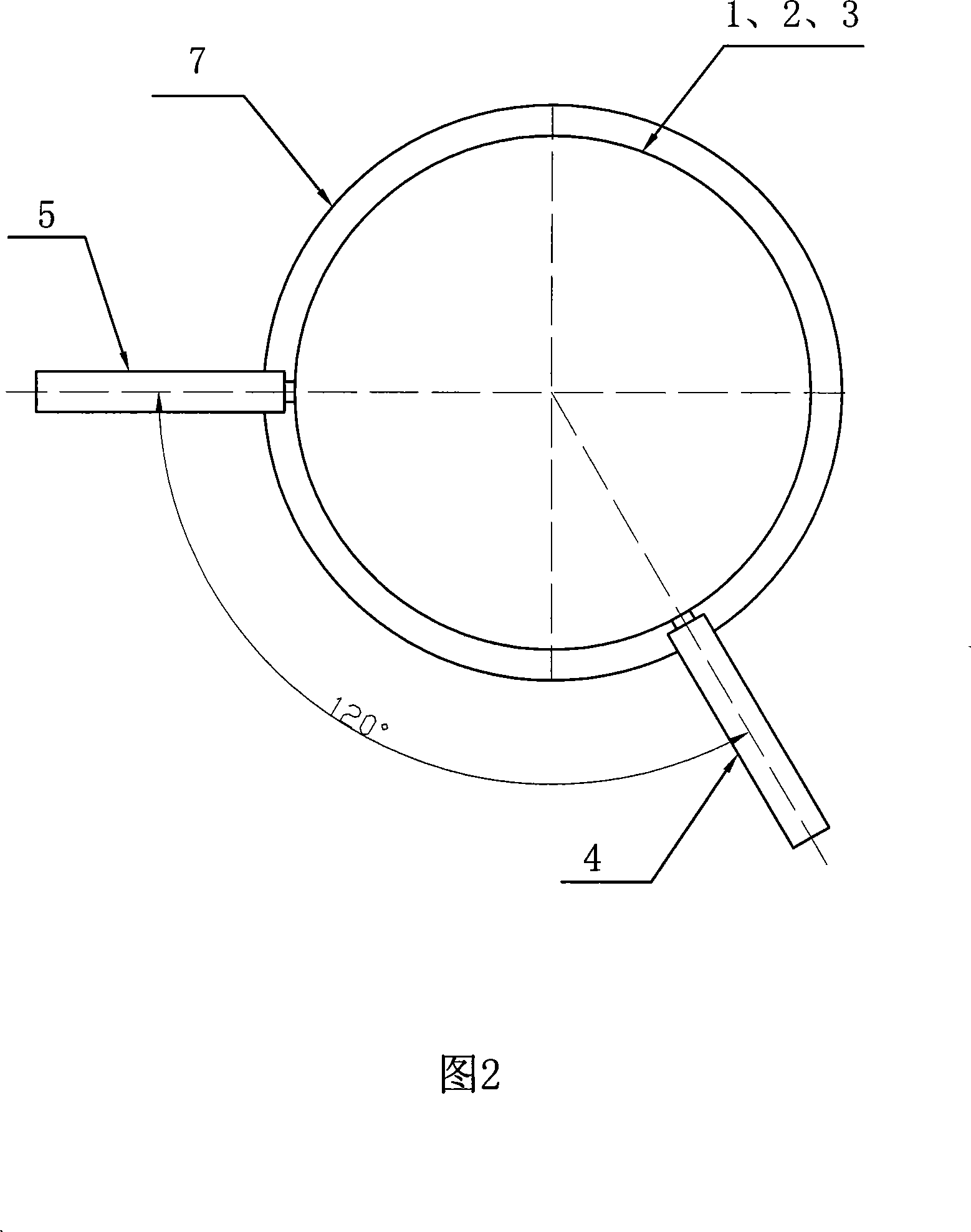

[0010] The present invention is described in further detail below in conjunction with accompanying drawing:

[0011] As shown in Figure 1 and Figure 2, on the 3M2150 cylindrical grinding machine, the electromagnetic centerless fixture is used to clamp two workpieces at the same time, and the grinding wheel cuts into the grinding method. The grinding wheel reciprocates at one time and can process two workpieces at the same time. This method It not only ensures the processing accuracy, but also improves the processing efficiency and reduces the cost.

[0012] The specific implementation steps are as follows:

[0013] 1) Install the positioning cylinder 1 on the workpiece shaft 7, and use the end surface of the grinding wheel 6 to grind the end surface of the positioning cylinder 1 smoothly. Positioning accuracy, so as to ensure processing accuracy;

[0014] 2) Adjust the fulcrum 4 and the fulcrum 5 of the electromagnetic centerless fixture, so that the two fulcrums are support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com