Bending-forming apparatus

A bending forming and bending technology, which is applied in the field of bending forming devices, can solve the problems of inability to meet the needs of reprocessing PVC materials, unable to meet great demands, and the product quality is not too hard, so as to achieve outstanding substantive characteristics and improve Production efficiency and product quality, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

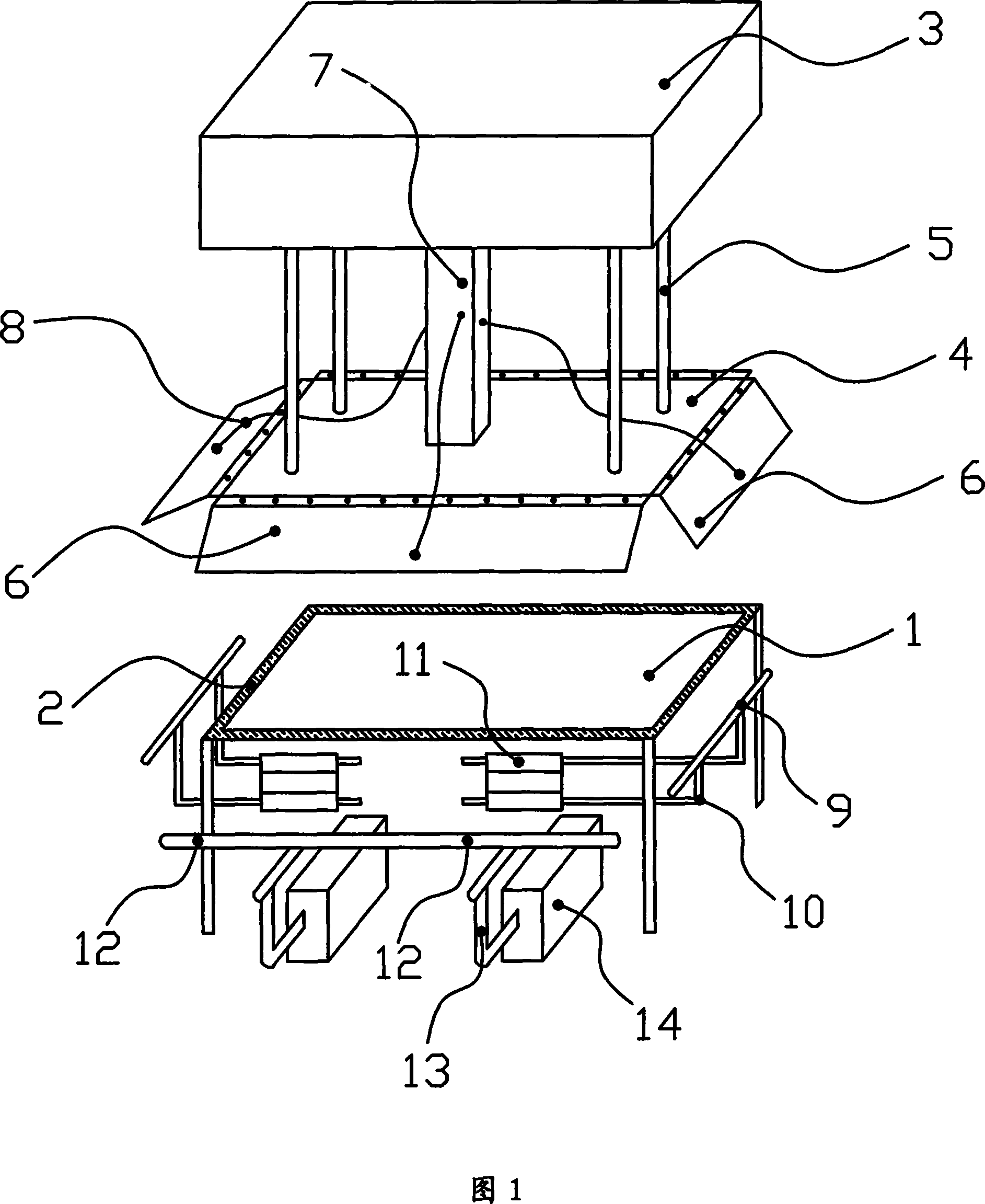

[0013] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

[0014] As shown in Figure 1, a bending and forming device includes a workbench 1, and a circle of heating and softening belt 2 is arranged at the four edges of the workbench 1, and the heating and softening belt 2 makes The PVC sheet softens and sags and bends.

[0015] A vertical pressure platform 4 is arranged above the workbench 1, and a vertical pressure plate 6 is movably connected to the four sides of the vertical pressure platform 4; usually, the vertical pressure plate 6 and the edge of the vertical pressure platform 4 are hinged. Structural connection, so that the outer end of the vertical pressure plate 6 can move up and down with the edge of the vertical pressure platform 4 as the axis;

[0016] The top of the vertical pressure platform 4 is provided with a vertical pressure platform lifting device 3 and a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com