Pneumatic compression sealing machine for pillow core

A sealing machine and pillow core technology, applied in the field of pneumatic pillow core compression sealing machine, can solve the problems of inaccurate product size, long maintenance time, high maintenance frequency, etc., and achieve high production speed, convenient transportation and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

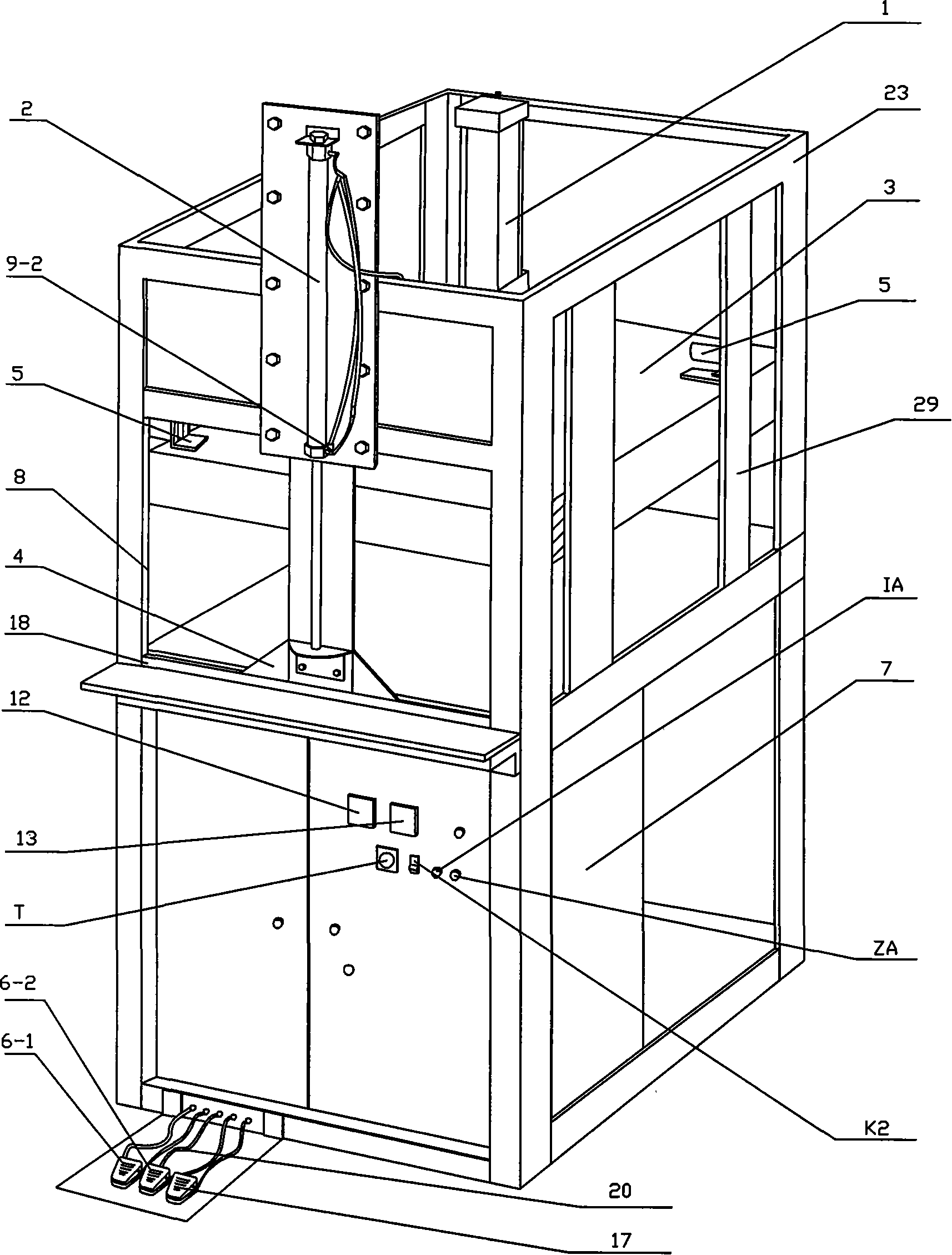

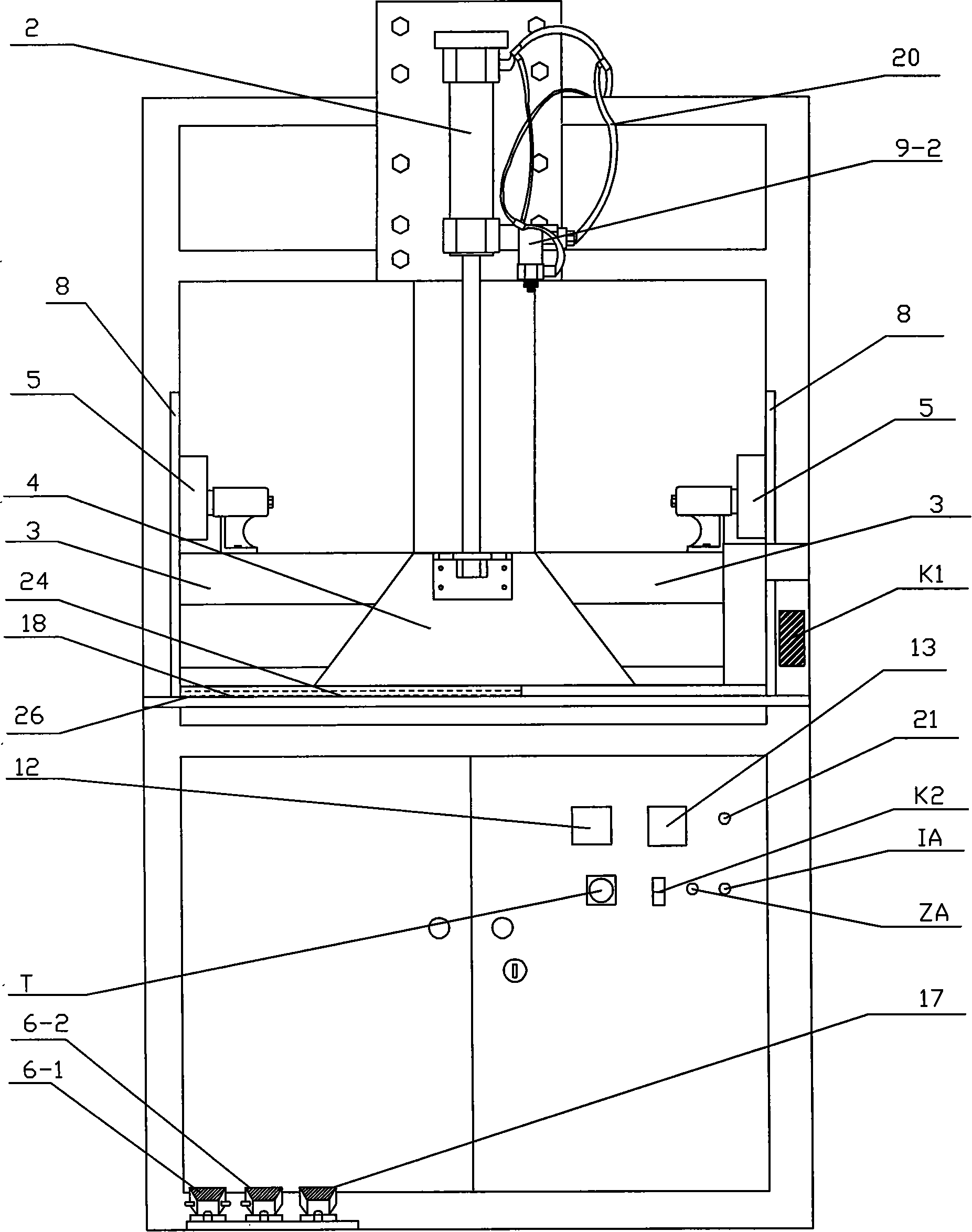

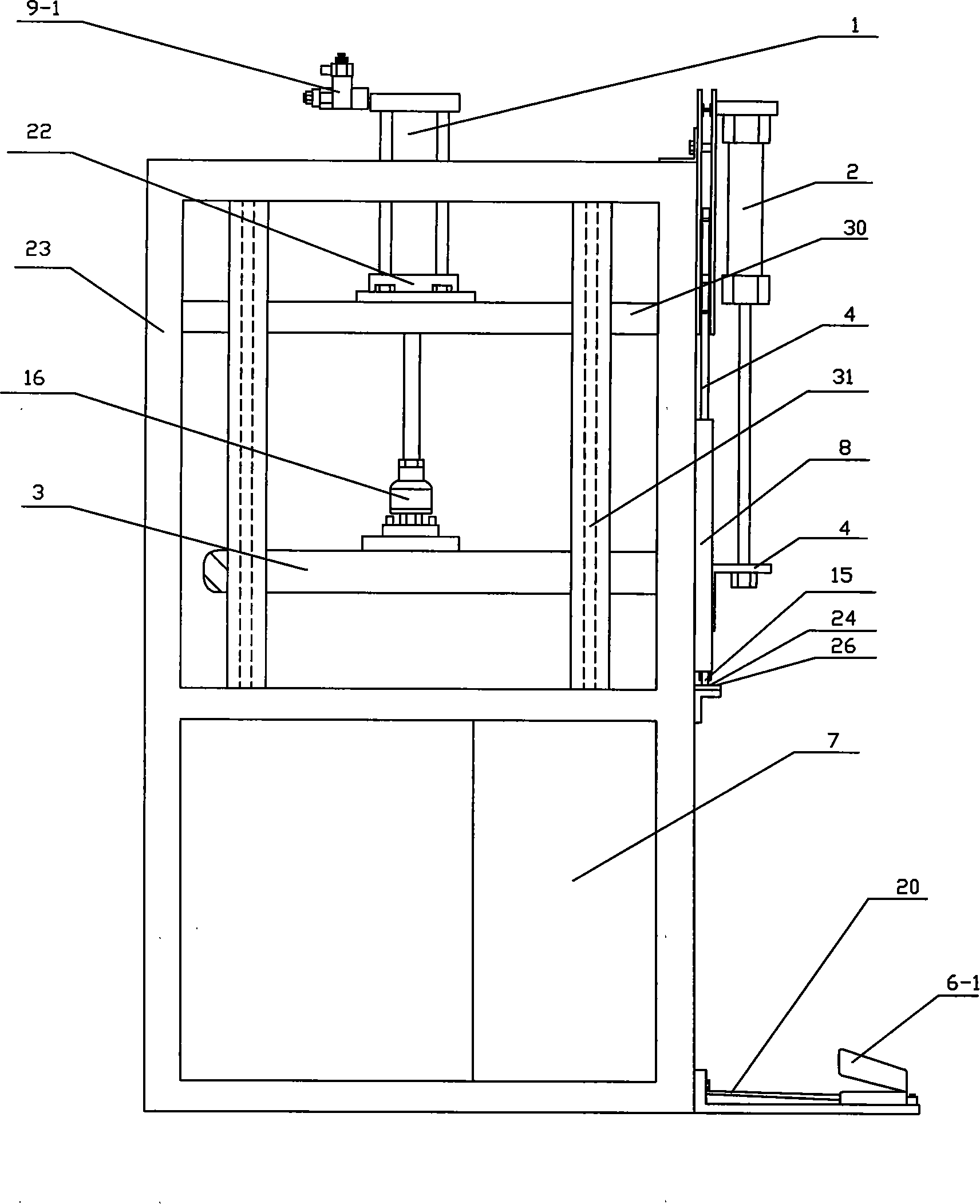

[0038] like figure 1 , figure 2 , image 3 As shown, the present invention includes a frame 23, and the form of the frame 23 is not limited. In the present embodiment, the frame 23 is a cabinet type and is divided into upper and lower parts, the upper part is a compression sealing device, and the lower part is a control box 7. Two angle irons 29 are respectively connected to the left and right sides of the compression sealing device, and slide rails 31 are arranged vertically on the inner walls thereof. The slide rail 31 is connected to the large pressure plate 3 through the small dining ladder guide shoe 5, and the center of the large pressure plate 3 is connected to the piston rod of the upper large cylinder 1 through the floating joint 16, and the large cylinder 1 is fixedly connected to the flange 22 through two parallel channel steels 30 In the middle upper end of frame 23. The small platen 4 is arranged in front of the upper end of the frame 23 and is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com