High hole dense perforation pressing crack sand controlling device for oil well

A technology with high porosity and pore pressure, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of high oilfield production, small sand control plug volume, and difficulty in large-scale promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

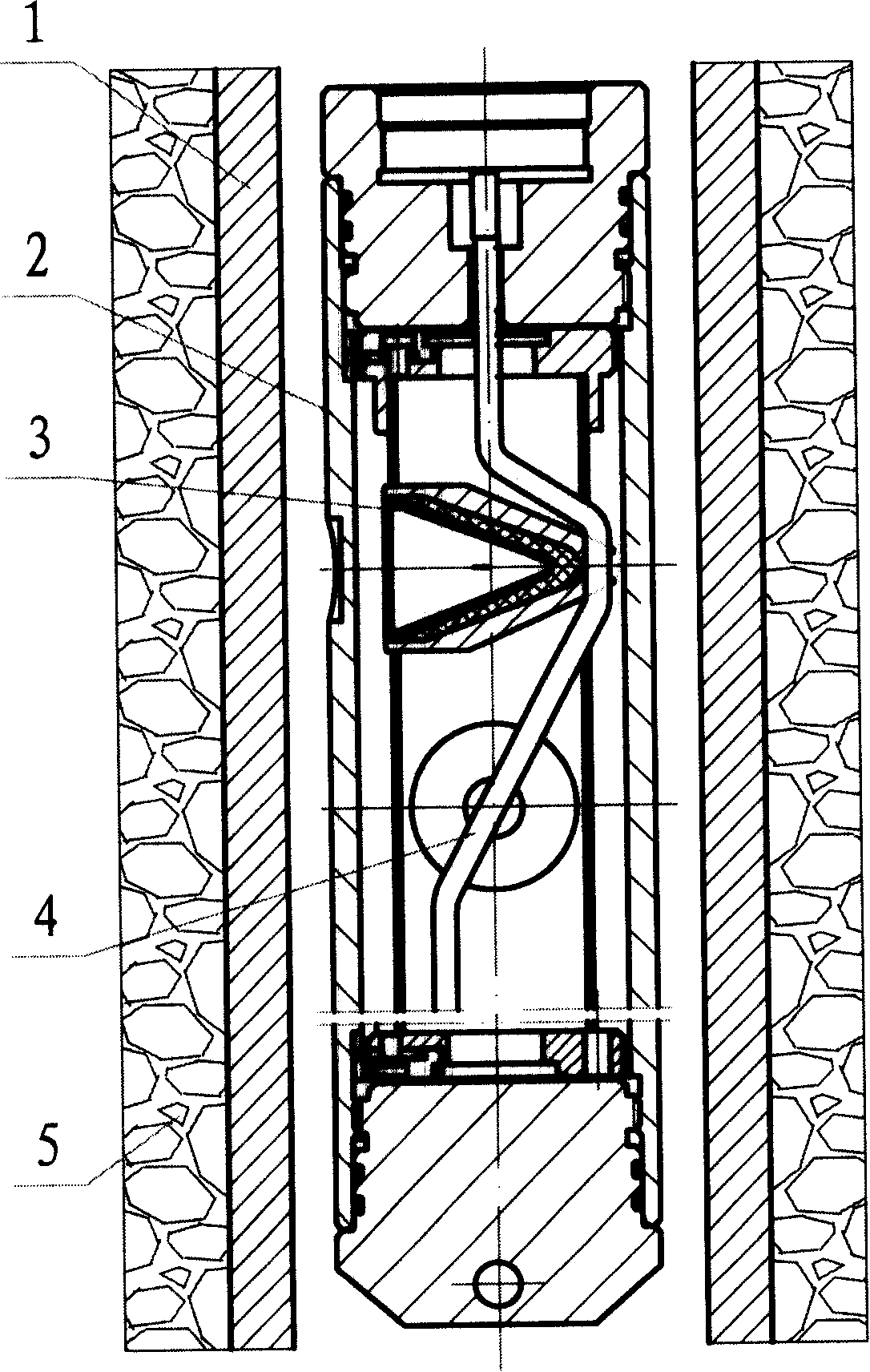

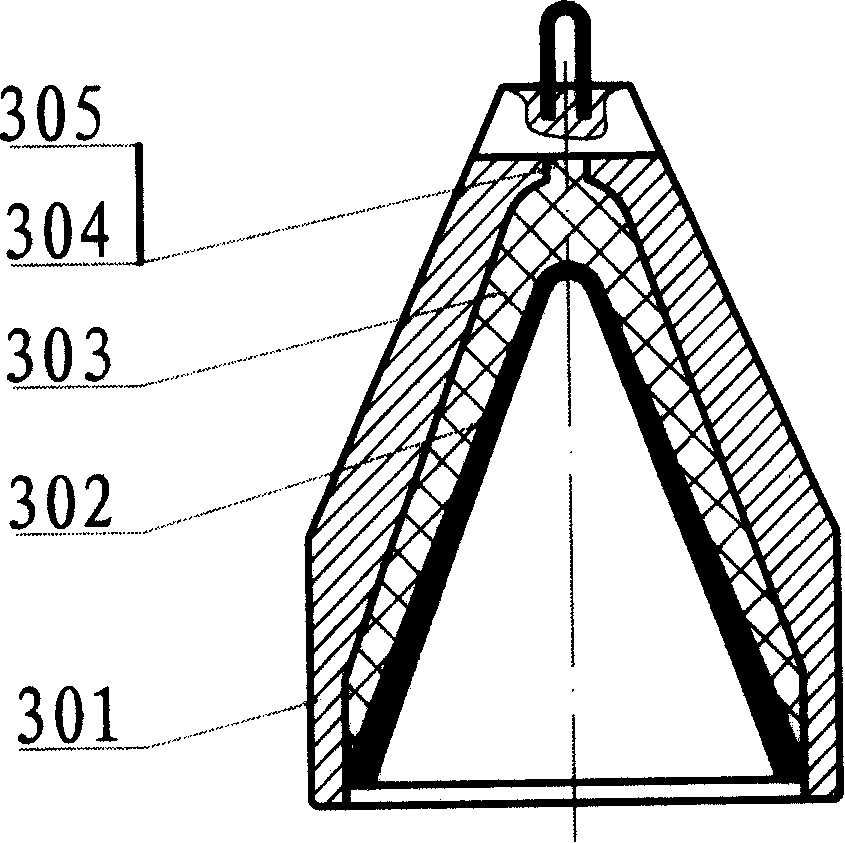

[0017] figure 1 It is a schematic diagram of oil well perforation operation during oil exploration and oil production. During oil production, the casing 1 should be drilled in the oil field, and the space between the casing 1 and the formation 5 should be reinforced with cement, and then the perforating device 3 should be loaded into the perforating gun 2, and inserted into the casing 1 to a proper depth. . When the depth is calibrated, the perforating operation can be performed.

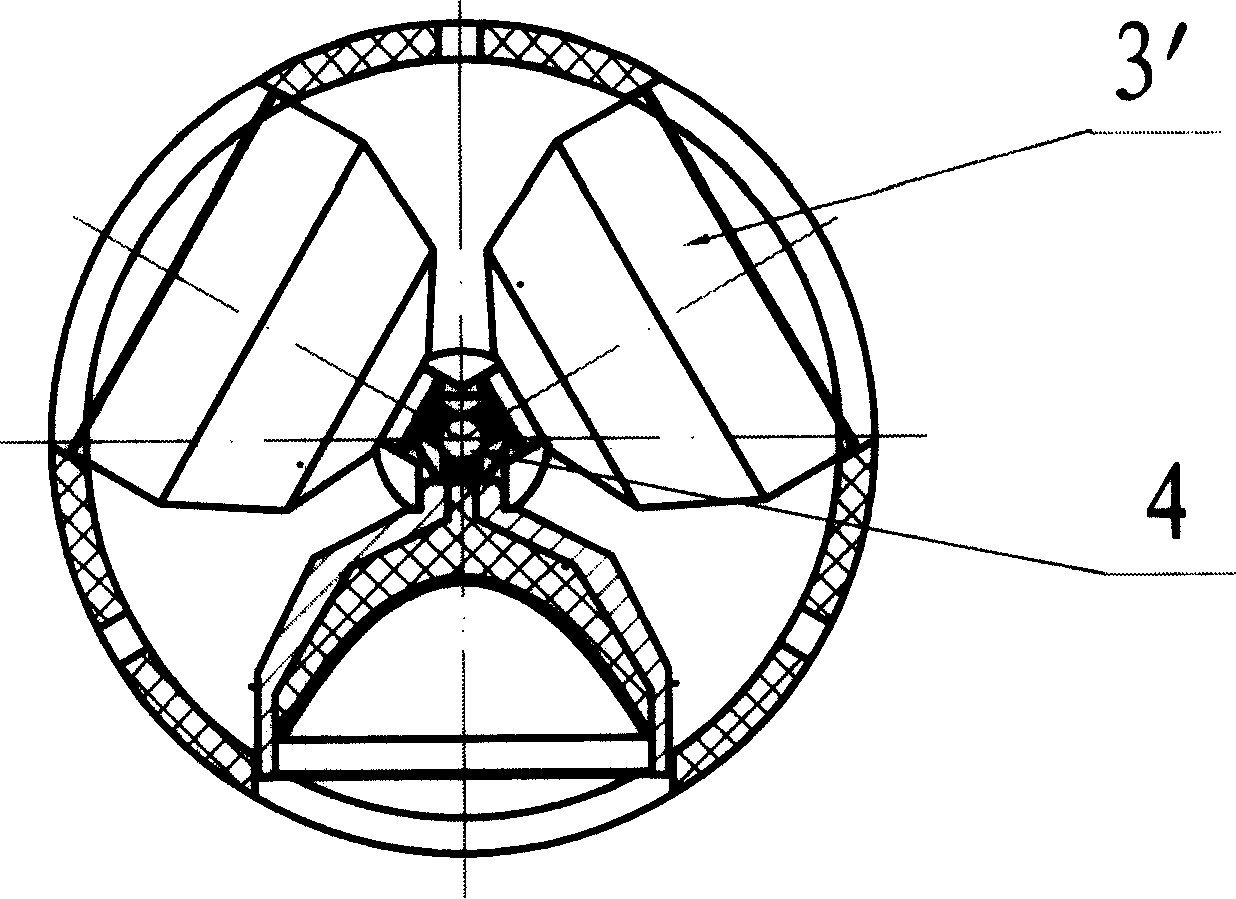

[0018] image 3 The petroleum perforating unit 3' that contains three perforating devices (3) used in the present invention is characterized in that three perforating devices 3 are placed on the position where ordinary perforating devices are usually placed, and the three are placed on their backs. At an angle of 120°, the detonating cord 4 passes through the middle of the detonation holes of the three perforators 3 and connects with the detonation holes.

[0019] Figure 4 For the embodiment (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com