Multicrystalline silicon compounds electric fuse silk part

A technology of silicided electricity and polysilicon, which is applied to electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of increased resistance at both ends of fuses, unstable recrystallization of polysilicon, and alignment errors affecting the size of three polysilicon regions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

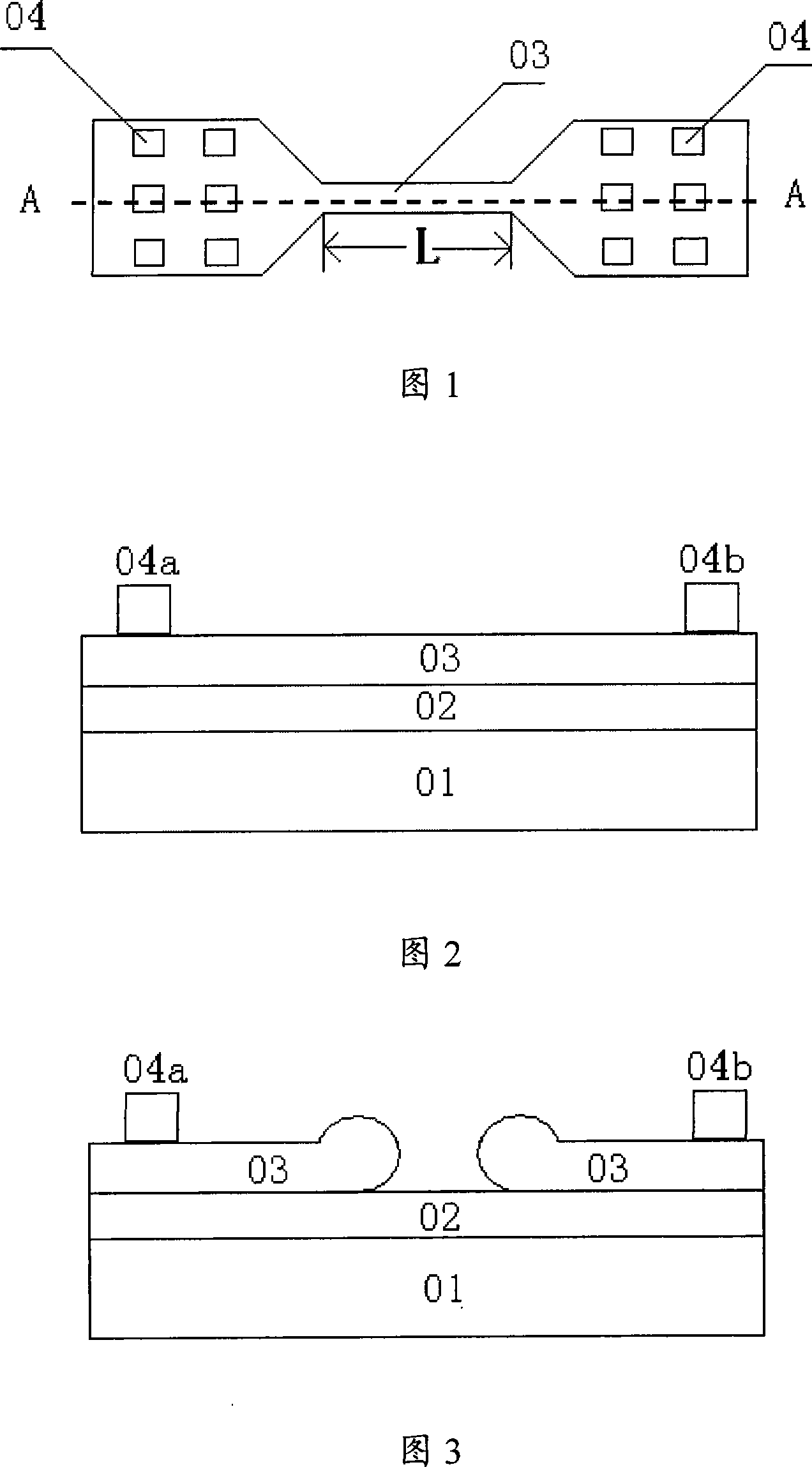

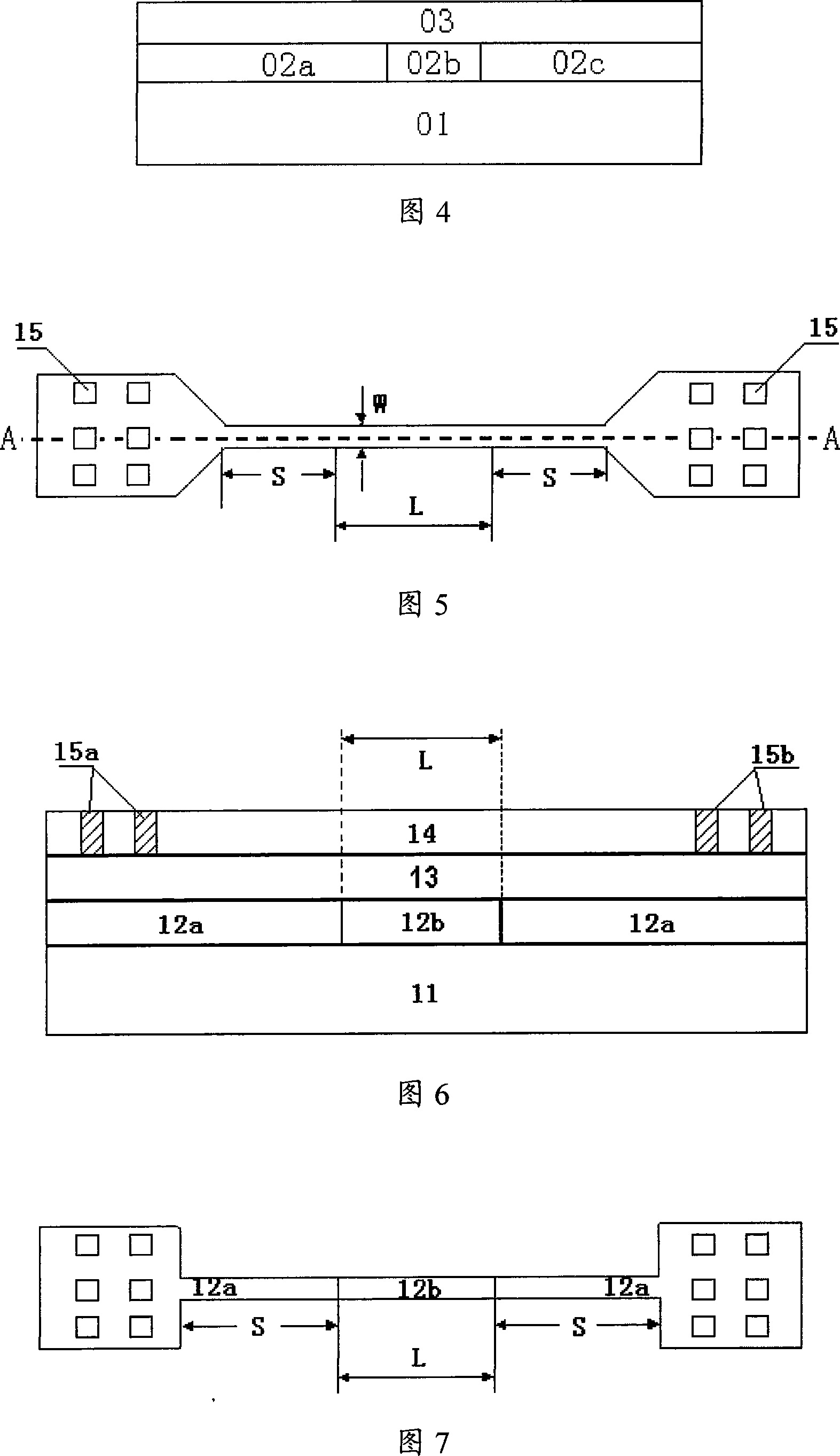

[0032] As shown in Figure 5 and Figure 6, a polysilicon silicide electric fuse device includes:

[0033] substrate 11,

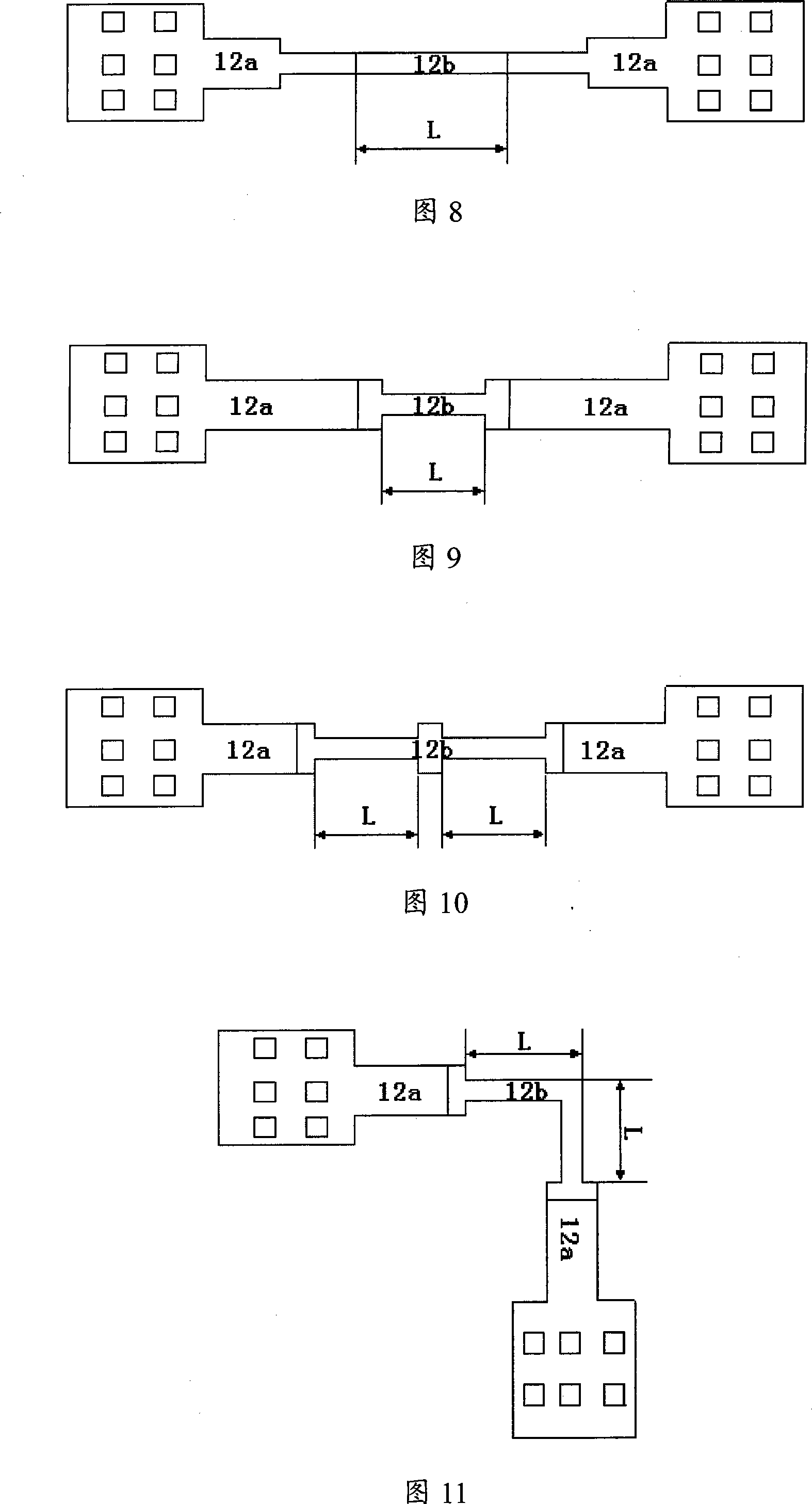

[0034] A semiconductor material layer 12 disposed on the substrate 11, the semiconductor material layer 12 includes lead-out regions 12a with the same type of doping at both ends and an undoped region in the middle or a middle region 12b with a lower doping concentration than the lead-out regions at both ends ; There are one or more fusing zones L in the middle zone 12b;

[0035] A metal silicide layer 13 disposed on the semiconductor material layer 12 .

[0036] Wherein, the metal silicide layer 13 is also provided with a dielectric layer 14, and the lead-out regions 12a at both ends of the dielectric layer 14 are respectively provided with one or more contact holes 15 penetrating to the metal silicide layer 13. .

[0037] Wherein, the semiconductor material layer 12 may be selected from one of semiconductor materials such as polysilicon, amorphous silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com