Ultrasonic probe and ultrasonic diagnostic apparatus

A technology of ultrasound and probes, which is applied in ultrasound/sonic/infrasonic diagnosis, sonic diagnosis, infrasonic diagnosis, etc. It can solve problems such as strength and uniformity without any consideration, and achieve excellent heat release characteristics, large attenuation rate, and high image quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

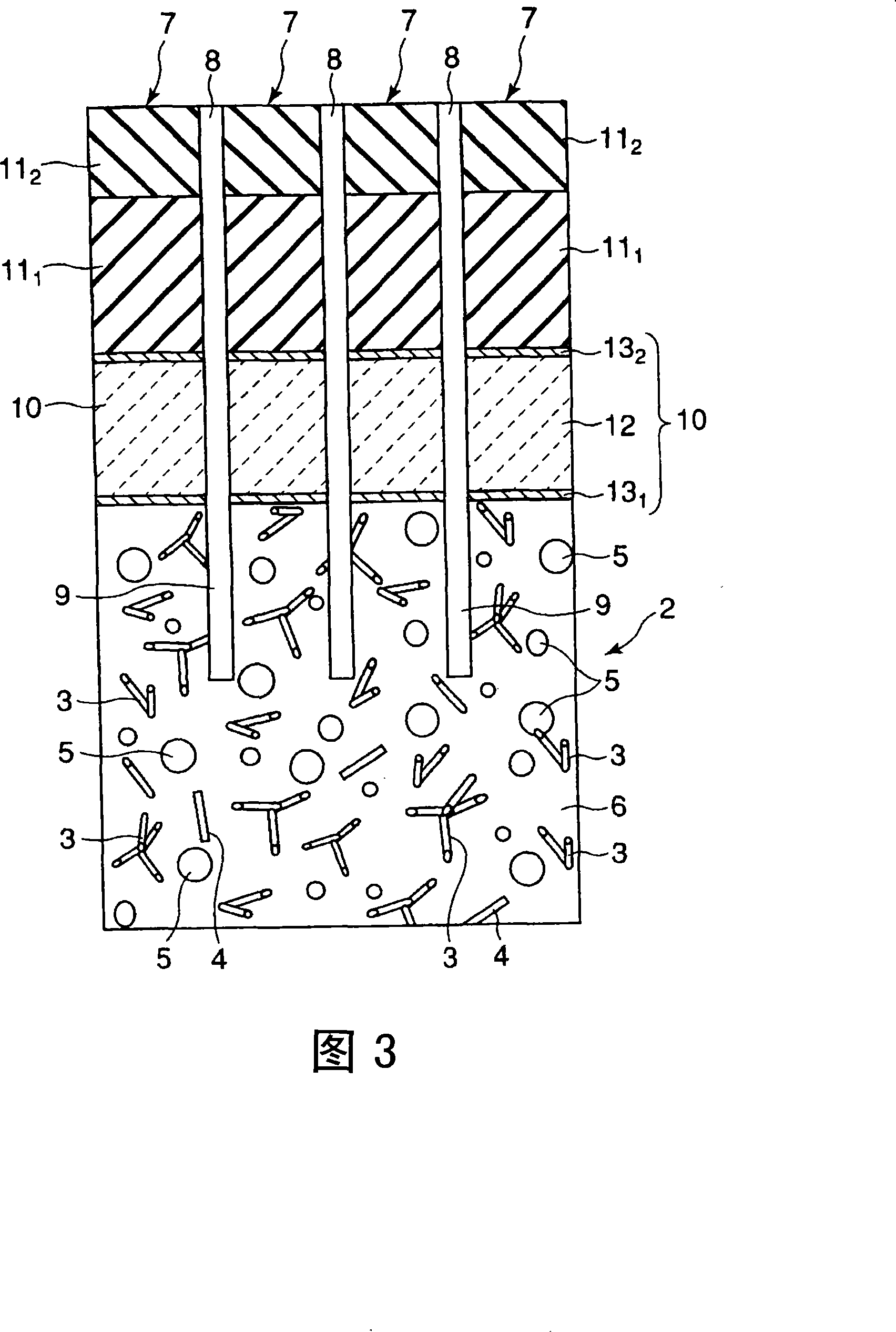

[0092] A plurality of tetrapod-shaped zinc oxide fibers (TPZ) are added as binding fibers to liquid epoxy resin (trade name manufactured by Emerson & Cuming, ェコビンド 27) [abbreviated as EPR]. The total amount was 3% by volume, and then a curing agent was added, put into a polyethylene container, stirred for 5 minutes with a rotary mixer, and uniformly mixed to prepare an acoustic backboard composition. The TPZ used here has a shape in which four zinc oxide fibers are bonded at one end and the other ends extend in different directions. Each zinc oxide fiber has a diameter of about 2 μm and a length of 40 to 50 μm. In addition, the shape in which four zinc oxide fibers of substantially the same length protrude in different directions and the one in which four zinc oxide fibers with a length in the range of 40 to 50 μm protrude in different directions exist in a mixture of multiple TPZs. shape.

[0093] Next, the acoustic backboard composition was subjected to a degassing treatmen...

Embodiment 2~7

[0095] Materials for acoustic backing layers were produced in the same manner as in Example 1, except that EPR, TZP, and the second filler were mixed in the ratios shown in Table 1 below.

Embodiment 8

[0097] Add a plurality of tetrapod zinc oxide fibers (TPZ) identical to Example 1 in liquid nitrile rubber (Japan Zeon company produces trade name, liquid NBR) [abbreviated as NBR], its relative to this NBR and TPZ The total amount is 5% by volume, and Fe with an average particle size of 5 to 10 μm is added at 5% by volume relative to the total amount of NBR and particles. 2 o 3 After the particles were placed in a polyethylene container, they were stirred for 5 minutes with a rotary mixer, and uniformly mixed to prepare an acoustic backboard composition. Next, this acoustic backboard composition was degassed for 10 minutes in a vacuum container, and placed in a container containing Teflon (registered trademark). Next, curing was performed at 80° C. for 24 hours to manufacture a material for an acoustic backing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com