Environment-protection husk absorbent charcoal activation furnace

A technology of activated carbon from shells and an activation furnace, which is applied in the field of environmental protection activated carbon activated carbon from shells, which can solve problems such as strict operating conditions, high product costs, and environmental pollution, and achieve low energy consumption, less product consumption, and reduced steam consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

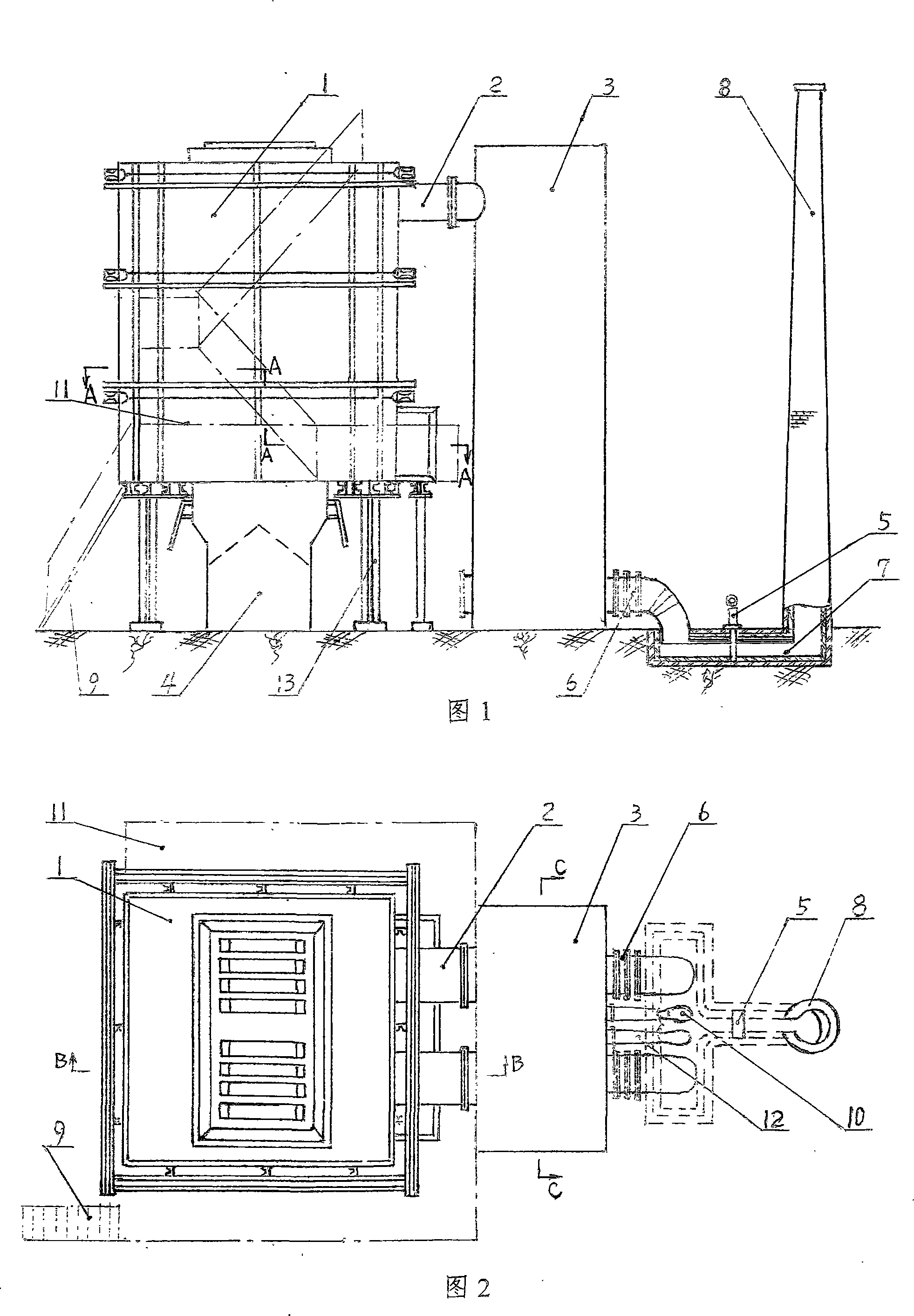

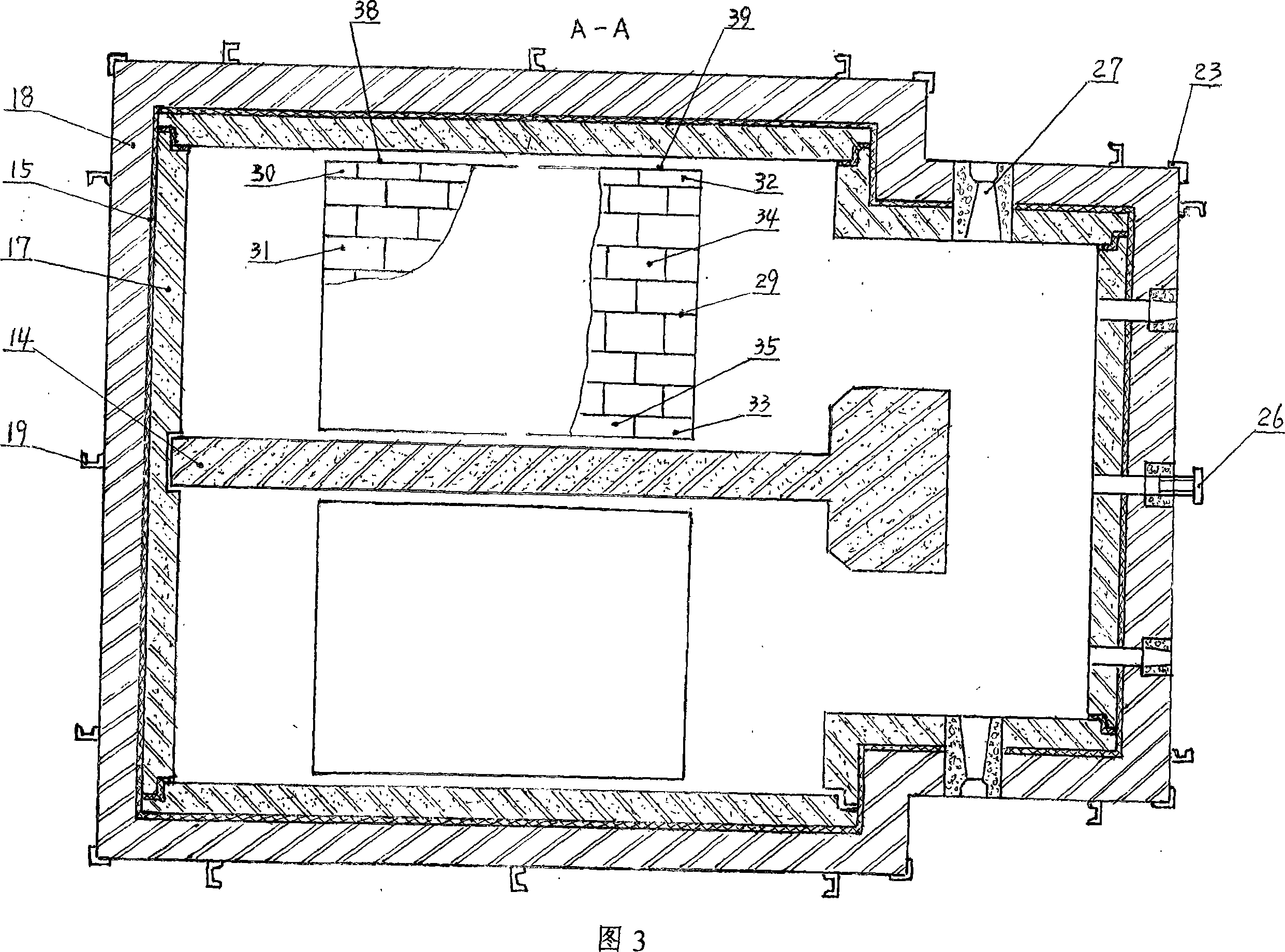

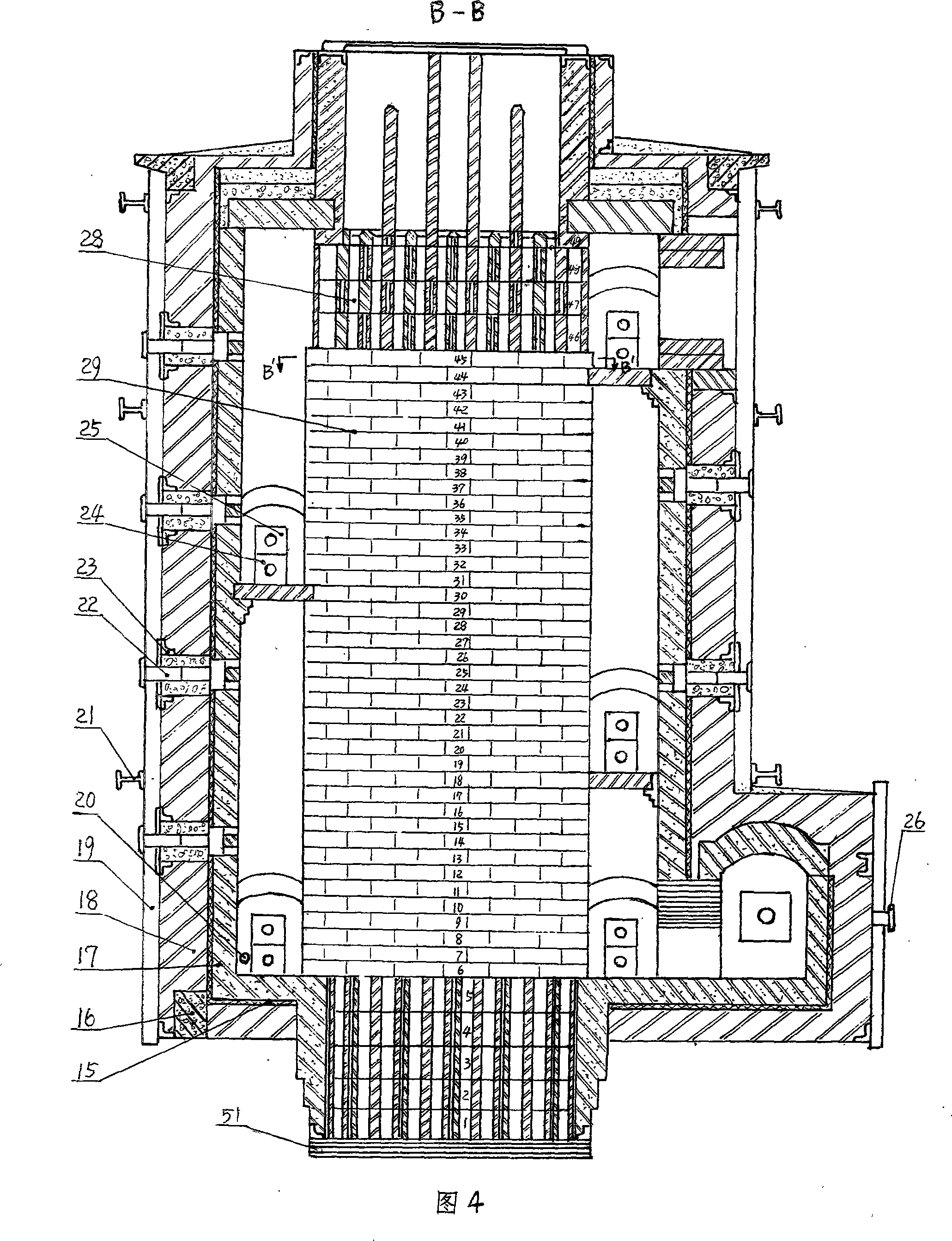

[0057]Referring to accompanying drawings 1 and 2, the activation furnace is mainly composed of furnace body 1, upper connecting flue 2, furnace foundation 4, flue main gate valve 5, waste gas, steam, air switching valve 6, flue 7 and chimney 8 and other devices Composition, which is characterized in that two adjacent half-furnaces are set in the furnace body 1, and each half-furnace is built with 8 kinds of special-shaped refractory bricks to form 80 product channels 28 and 360 horizontal channels 29, and the product channels 28 are set as arcs; Between the furnace body 1 and the chimney 8, red machine bricks are set for the outer wall, clay refractory bricks are used for the inner wall, and diatomite bricks are used in the middle. The heat exchange chamber 3 is divided into two chambers 45 by a partition wall 48. The upper connecting flue 2 communicates with the activation furnace respectively. At the bottom of the heat exchange chamber 3, two steam pumps 10 are installed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com