A wood chip fuel heating furnace and its use method

A heating furnace and wood chip technology, applied in the direction of botany equipment and methods, applications, air heaters, etc., can solve the problems of reduced effective area of greenhouses, uneven temperature distribution, high fuel costs, etc., and achieve low cost of transformation and simple structure , the effect of long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

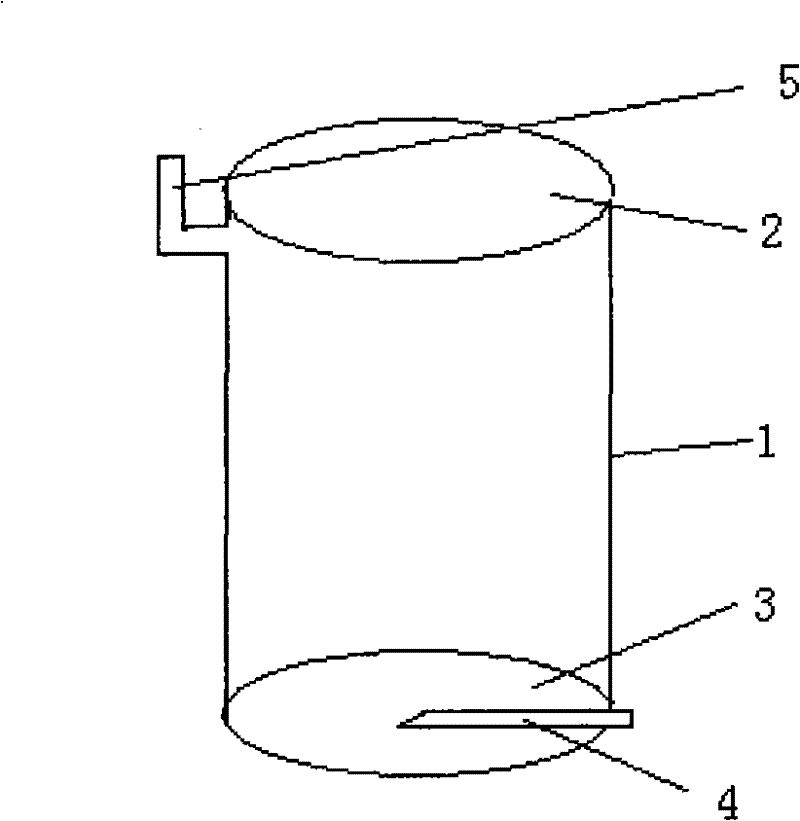

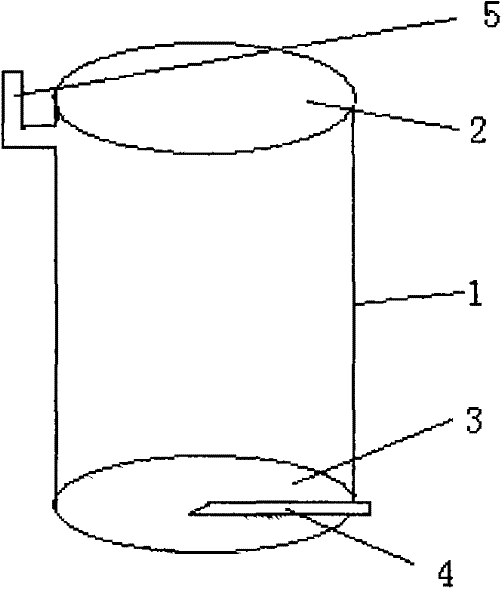

[0014] 1. Processing and production of heating furnace

[0015] (1) Preparation materials: buy 1 waste diesel barrel; an iron pipe with a diameter of 8-10 cm, a length of 35-40 cm, and a thickness of about 3 mm; a piece of scrap iron sheet with a length and width of about 80 cm and a thickness of 1.5-2 mm ; Go to the white iron production office, process a white iron elbow with a diameter of 8-10 cm, two sections each 15 cm long, and a thickness of 1.5 mm. 10mm round steel 20cm.

[0016] (2) Welding the air inlet pipe: please welder first cut one end of the iron pipe into a 45°C oblique head as the air inlet pipe, and then open a hole with a diameter equal to the outer diameter of the air inlet pipe on the barrel wall near the bottom of the diesel barrel. Insert one end of the flat mouth of the air inlet pipe, protruding about 2cm from the wall of the barrel, place the end of the oblique head on the center of the bottom of the diesel barrel, with the oblique opening facing up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com