Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

A plant fiber and magnesium-calcium technology, applied in the field of building materials, can solve the problems of waterproof, fireproof, anticorrosion, mothproof performance, cost increase, environmental pollution and other problems, and achieve good wind and rain erosion performance, small equipment investment and quick results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

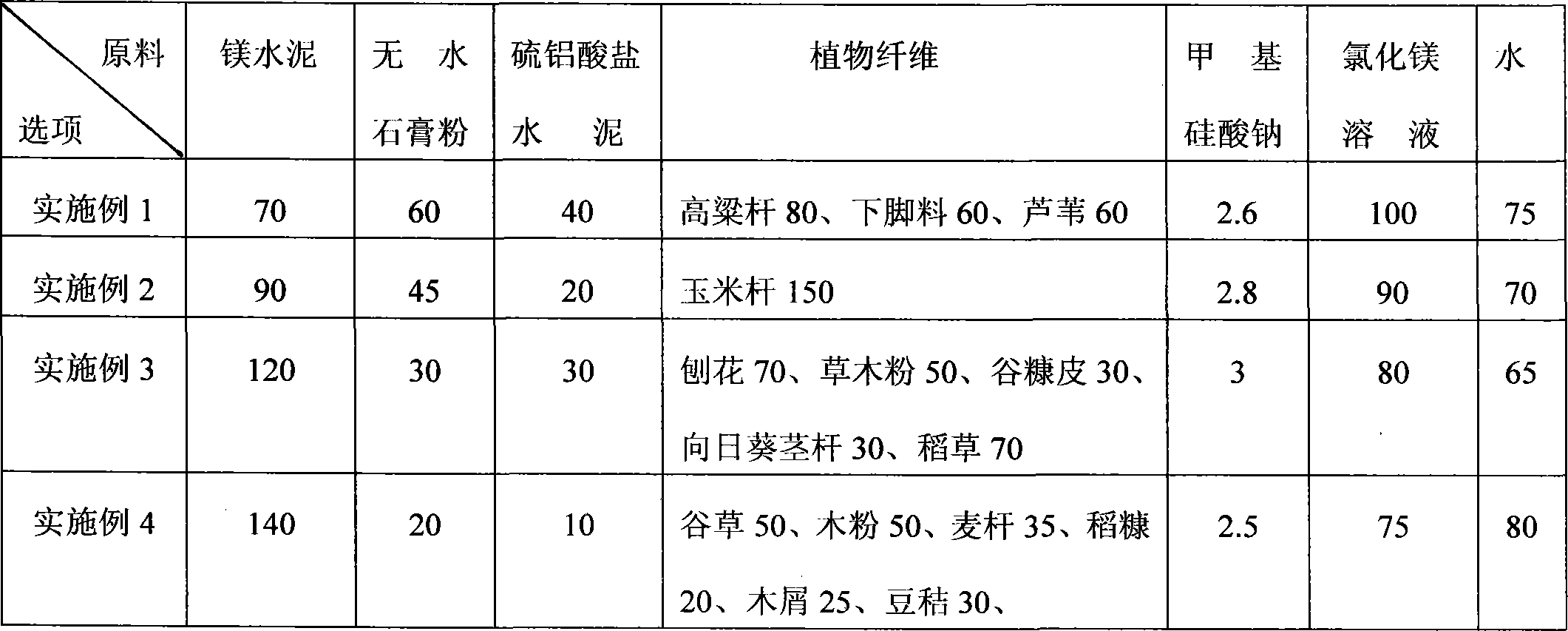

[0028] Magnesium-calcium fireproof plant fiberboard is composed of four parts: inorganic gelling material, plant fiber, sodium methyl silicate and stirring solution. Each raw material weight component is:

[0029] 1-2.4 parts of inorganic cementitious material, including: 0.7-1.4 parts of magnesium cement; 0.2-0.6 parts of anhydrous gypsum powder; 0.1-0.4 parts of sulphoaluminate cement. Magnesium cement is mainly used as a cementing agent. It is required that the magnesium cement must be high in silicon and low in calcium, and the active magnesium oxide should be between 62%±2. Its parameters are: MgO 80-86%, active CaO 1.0-1.5%, SiO 2 3.5~4.5%, Al 2 o 3 2.2~2.9%, Fe 3 o 4 1.0-2.0%; loss on ignition is 3-11%. 0.1-0.4 parts of sulphoaluminate cement, its function is early strength and waterproof.

[0030] 1.5-2.5 parts of plant fiber, including one or more of crop plant fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com